AdjustingtheMotionControl

Levers

AdjustingtheHeight

Themotioncontrolleverscanbeadjustedhigheror

lowerformaximumoperatorcomfort.

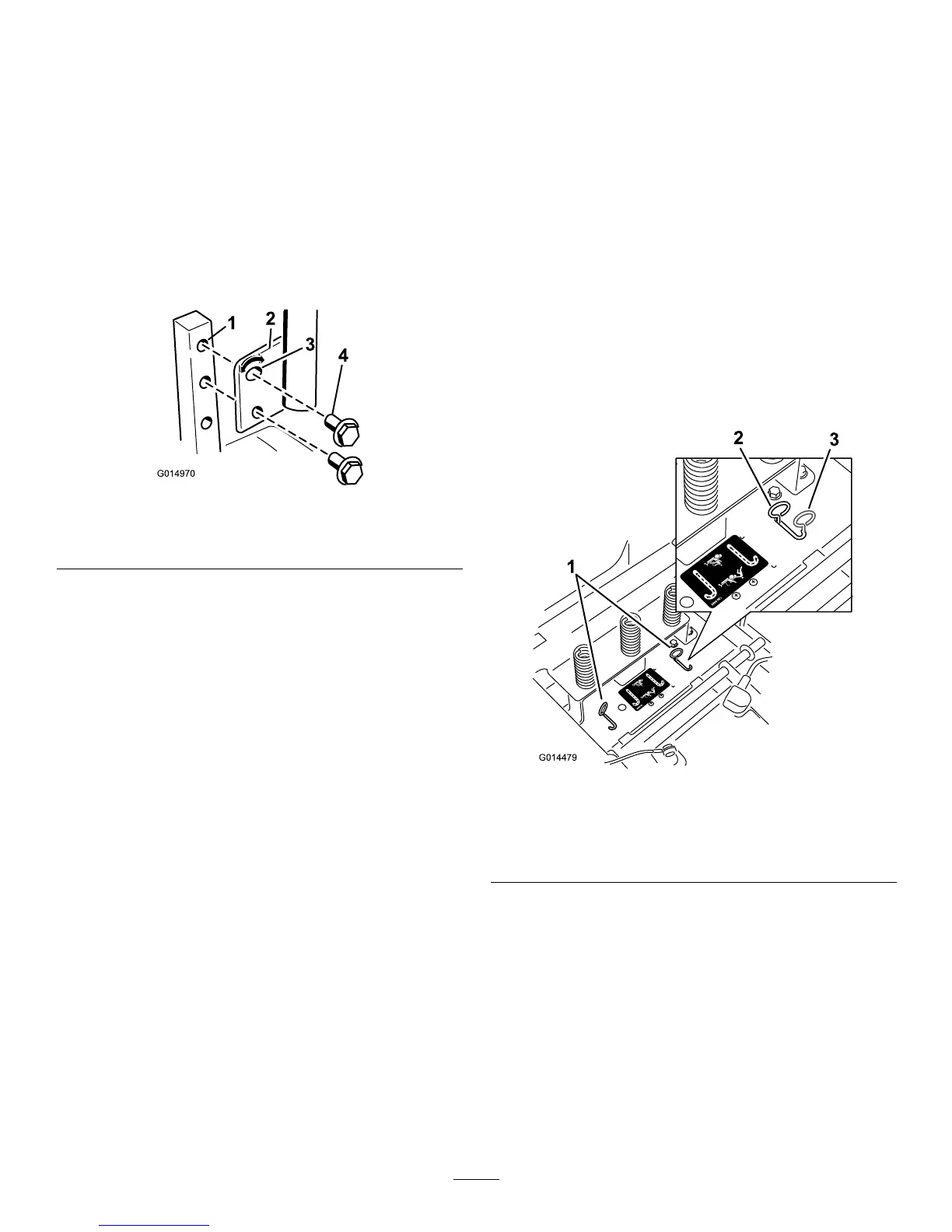

1.Removethe2boltsholdingthecontrollevertothe

controlarmshaft(

Figure23).

2.Movethecontrollevertothenextsetofholes.

Securetheleverwiththe2bolts(Figure23).

Figure23

1.Controlarmshaft3.Slotted,upperhole

2.Controllever

4.Bolt

3.Repeattheadjustmentfortheoppositecontrol

lever.

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrolleverto

thecontrolarmshaft.

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforeoraft(

Figure23).Tightenboth

boltstosecurethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrol

lever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausedamagemay

occur.

Thismachinehasanelectricbrakemechanismandto

pushthemachinetheignitionkeyneedstobeinthe

Runposition.Thebatteryneedstobechargedand

functioningfortheelectricbraketobedisengage.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtopark

position,stoptheengine,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

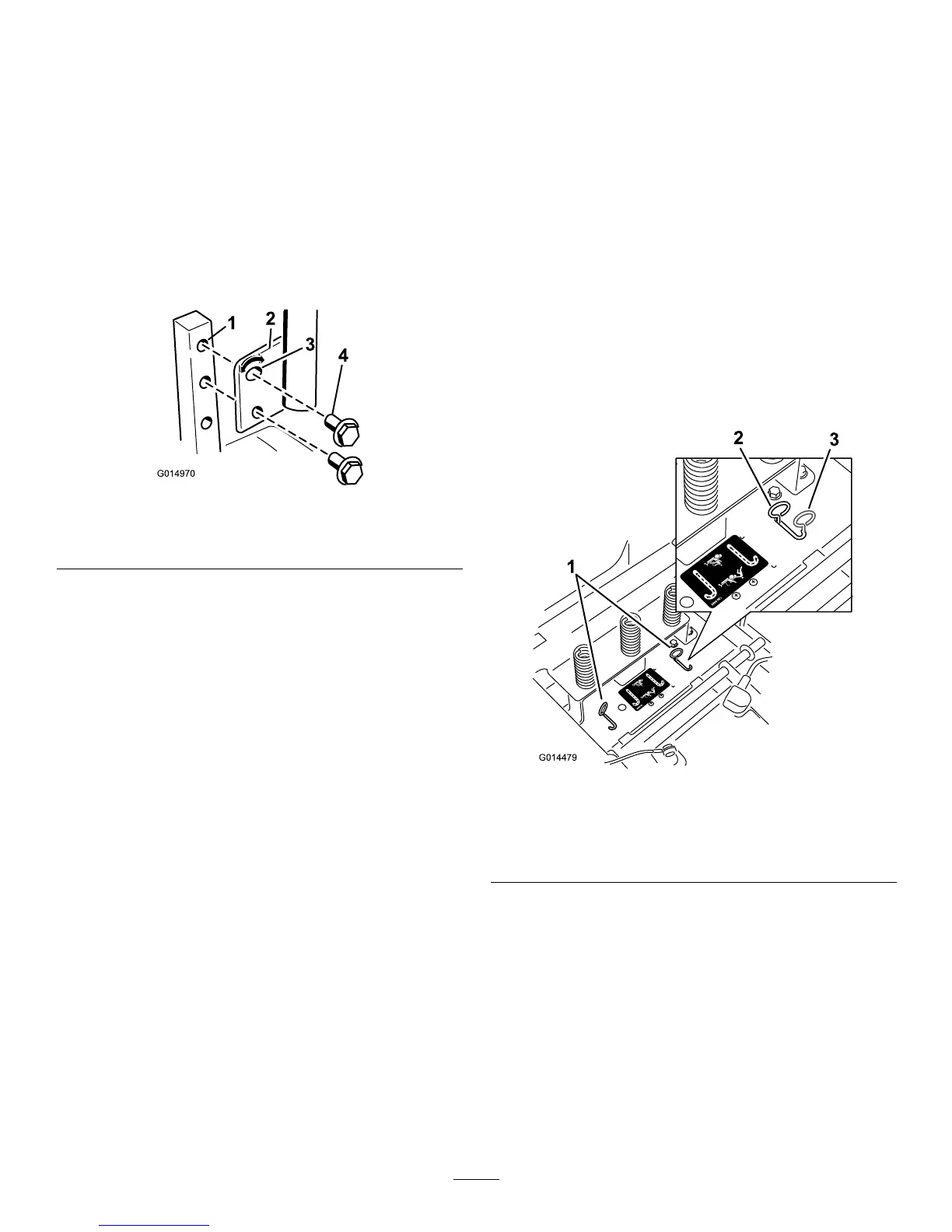

3.Raisetheseattolocatethebypassleversbehindthe

battery,ontheframe.

4.Movethebypassleversforwardsandthenout

tolocktheminplaceasshownin

Figure24to

disengagethewheelmotors.Repeatthisforeach

lever.

5.Lowertheseatandmovethemotioncontrollevers

inwardtotheneutralpositionandturntheignition

keytotherunposition.Donotstartthemachine.

Themachineisnowabletobepushedbyhand.

Figure24

1.Bypassleverlocations

3.Leverpositionforpushing

themachine

2.Leverpositionfor

operatingthemachine

6.Whennished,ensurethekeyhasbeenreturned

totheStoppositiontoavoiddrainingthebattery

charge.

Ifthemachinefailstomovetheelectricbrake

maystillbeengaged.Ifnecessarytheelectric

brakecanbereleasedmanually.Refertothe

ReleasingtheElectricBrake(page33)procedurein

DriveMaintenance.

21

Loading...

Loading...