2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

3.Disengagethebladecontrolswitchandmovethe

motioncontrolsoutwardtotheparkposition.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

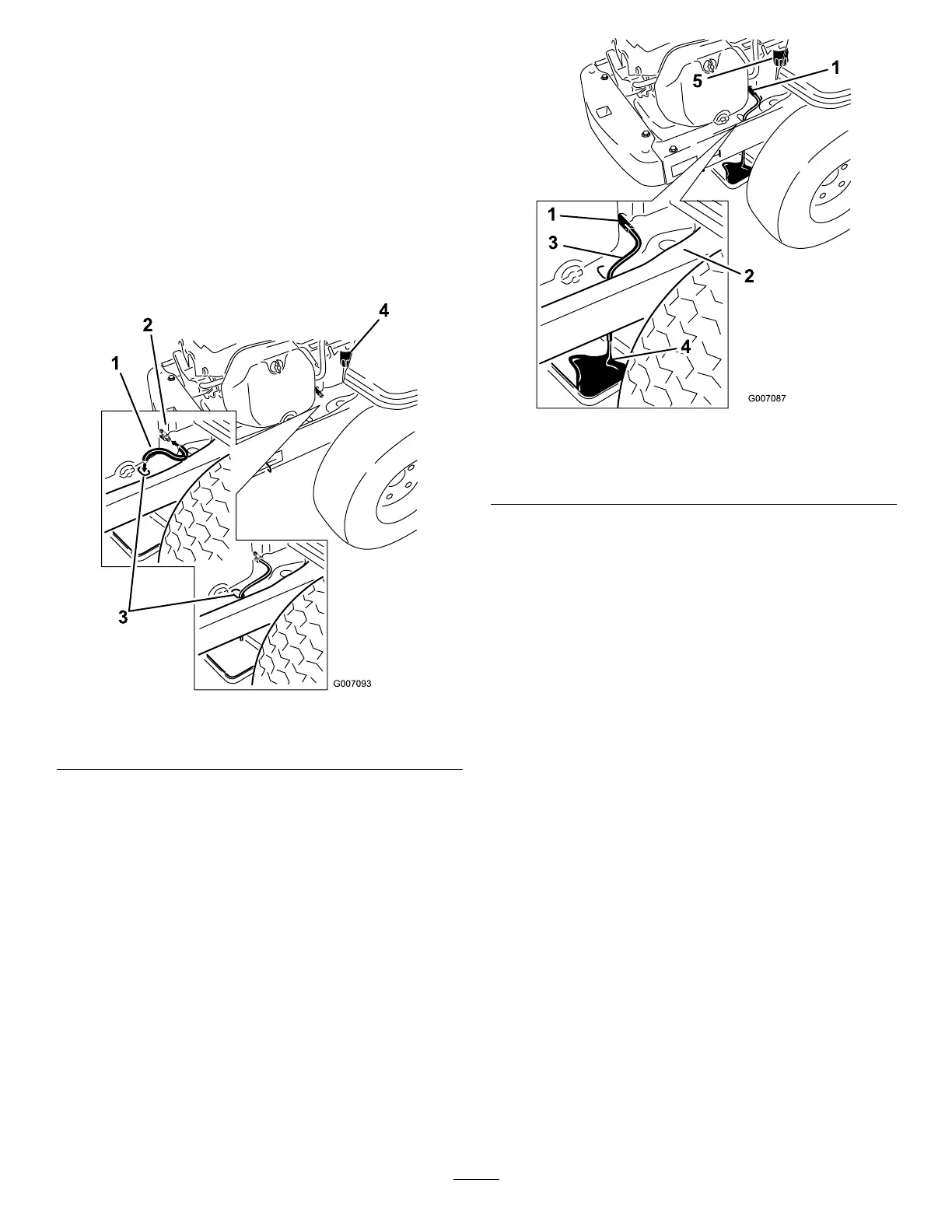

5.Cleantheareaaroundthedrainvalveandonthe

machineframe.Locatetheoildrainhoseandslide

itoverthedrainvalve(Figure32).

Figure32

1.Oildrainhose3.Holeinframe

2.Drainvalve

4.Oillter

6.Placetheoppositeendoftheoildrainhosethrough

thedrainholeintheframe(Figure32).

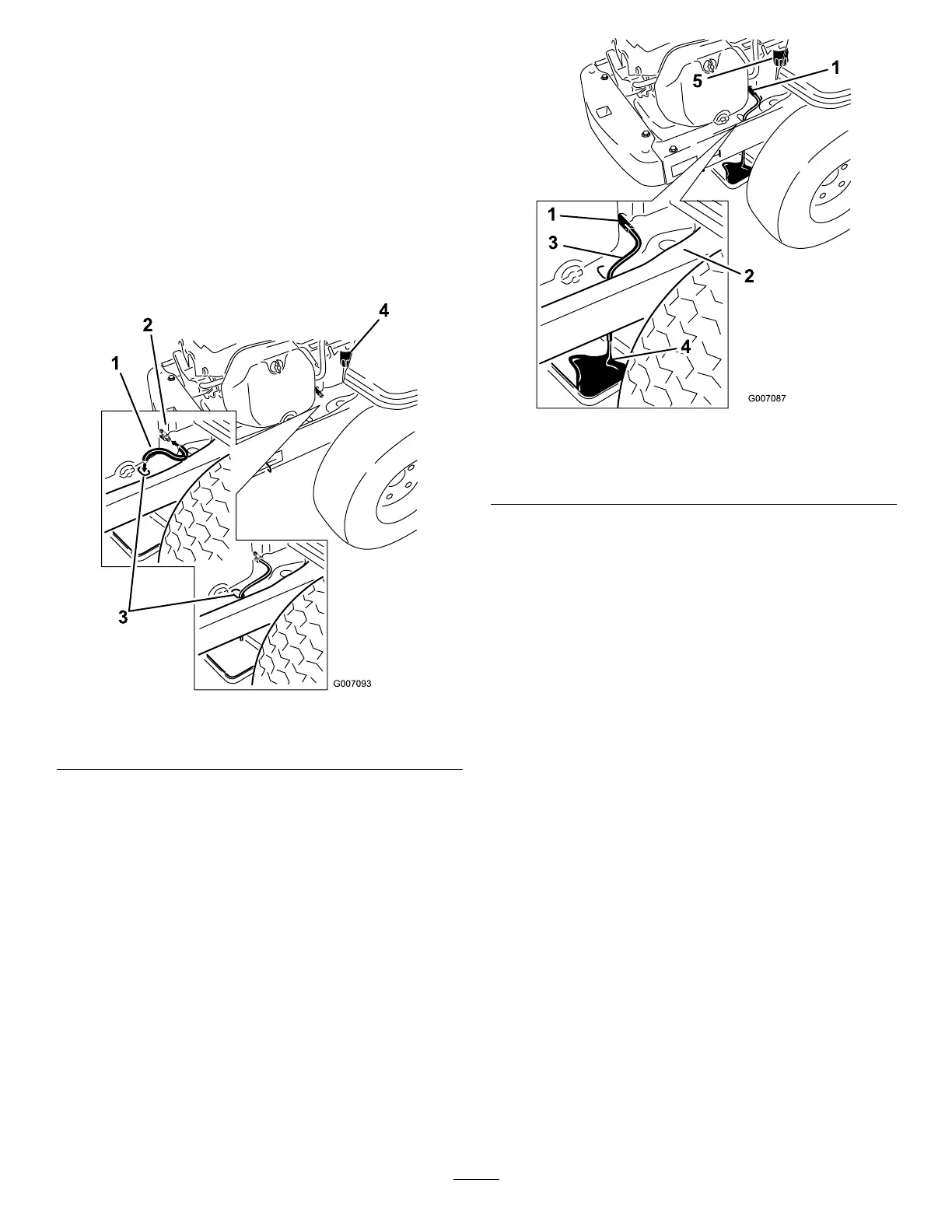

7.Placeapanunderneathmachinedirectlybelowthe

drainholeintheframeasshowninFigure33.

Figure33

1.Oildrainvalve

4.Pan

2.Machineframe5.Oillter

3.Oildrainhose

8.Turnthedrainvalve1/4counterclockwisetoopen

andallowtheoiltodrain(Figure33).Removethe

oilllcap/dipstick(Figure31).

9.Besuretoallowampletimeforcompletedrainage.

10.Removetheoldlterandwipeoffthemountingpad

(Figure33).

11.Whenoilhasdrainedcompletely,closetheoildrain

valve.Removetheoildrainhoseandwipeupany

excessoilontheframe(Figure33).

Note:Disposeoftheusedoilatarecyclingcenter.

12.Placethenewreplacementlterinashallowpan

withtheopenendup.Pournewoiloftheproper

type,inthroughthethreadedcenterhole.Stop

pouringwhentheoilreachesthebottomofthe

threads.Allowaminuteortwofortheoiltobe

absorbedbytheltermaterial.

13.Applyathinlmofcleanoiltotherubbergasketon

thenewlter.

14.Installthereplacementoilltertothemountingpad.

Turntheoillterclockwiseuntiltherubbergasket

contactsthepad,thentightenthelteranadditional

2/3to1turn(Figure34).

30

Loading...

Loading...