–8–

EN

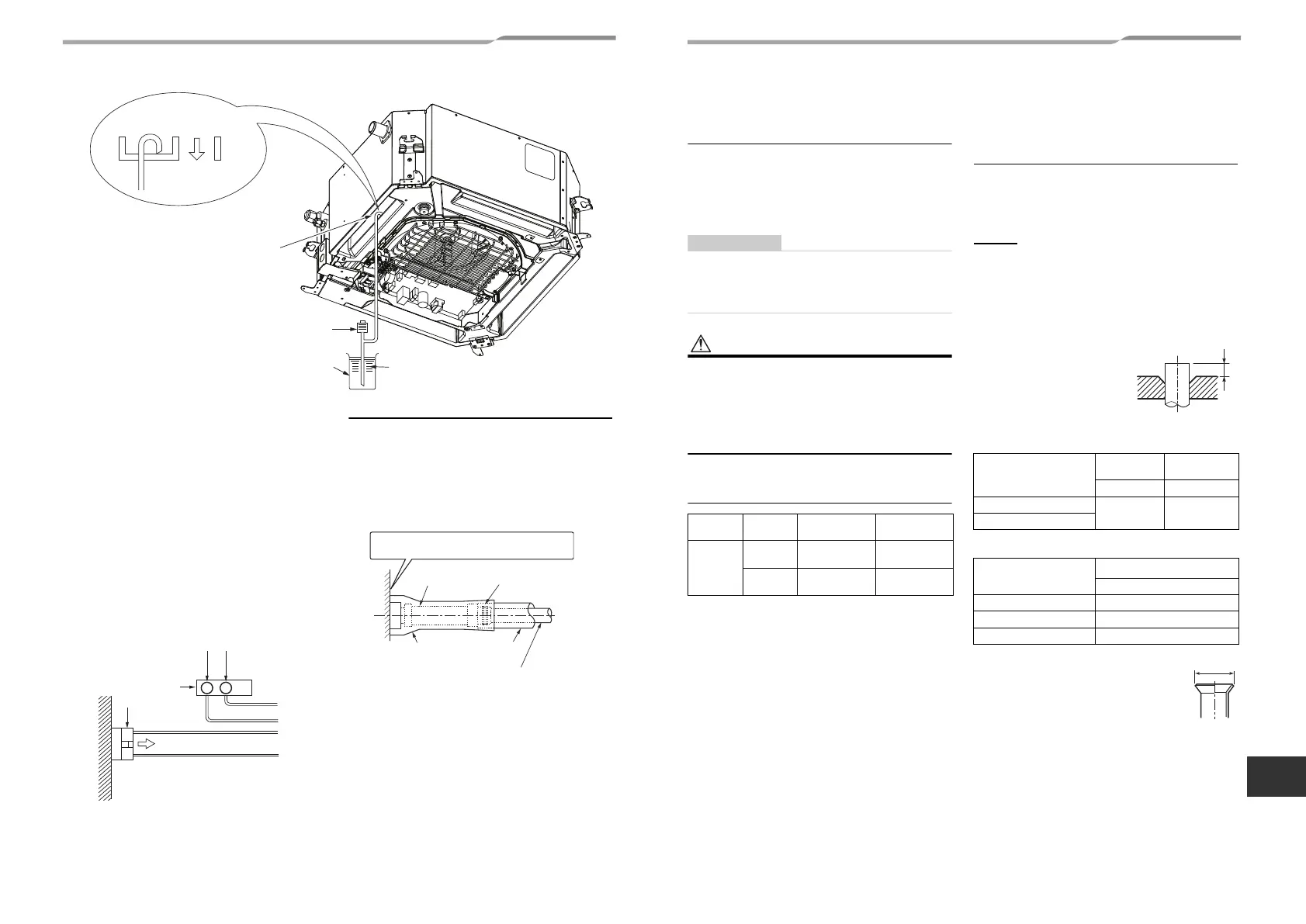

• After the electric work has finished, pour water

during COOL mode operation.

• If the electric work has not yet finished, pull out the

float switch connector (CN34: Red) from the

electrical control box, and check draining by plugging

the single phase 208/230 V power to the terminal

blocks L

1 and L2.

If doing so, the drain pump motor operates.

• Test water drain while checking the operation sound

of the drain pump motor.

(If the operation sound changes from continuous

sound to intermittent sound, water is normally

drained.)

After the check, the drain pump motor runs,

connecting the float switch connector.

(In case of check by pulling out the float switch

connector, be sure to return the connector to the

original position.)

Perform heat insulating

• As shown in the figure, cover the flexible hose and

hose band with the attached heat insulator up to the

bottom of the indoor unit without gap.

• Cover the drain pipe seamlessly with a heat insulator

to be procured locally so that it overlaps with the

attached heat insulator of the drain connecting

section.

* Direct the slits and seams of the heat insulator

upward to avoid water leakage.

Air discharge

area

Insert the leading part of the hose

between the heat exchanger and

the drain pan, and then bend it

downward.

Polyethylene hand

pump for pouring

water in drain pan

Water (0.4-0.5 gal

(1500 cc to 2000 cc))

Vessel

Drain pan

Pull out connector CN34 (Red)

from P.C. board.

CN34

(RED)

Black

Black

Red

White

Power

terminals

208/230-1-60

Wrap the attached heat insulator seamlessly from

the surface of the indoor unit.

Flexible hose

Hose band

Attached heat

insulator

Heat insulator to be

procured locally

Hard vinyl chloride pipe

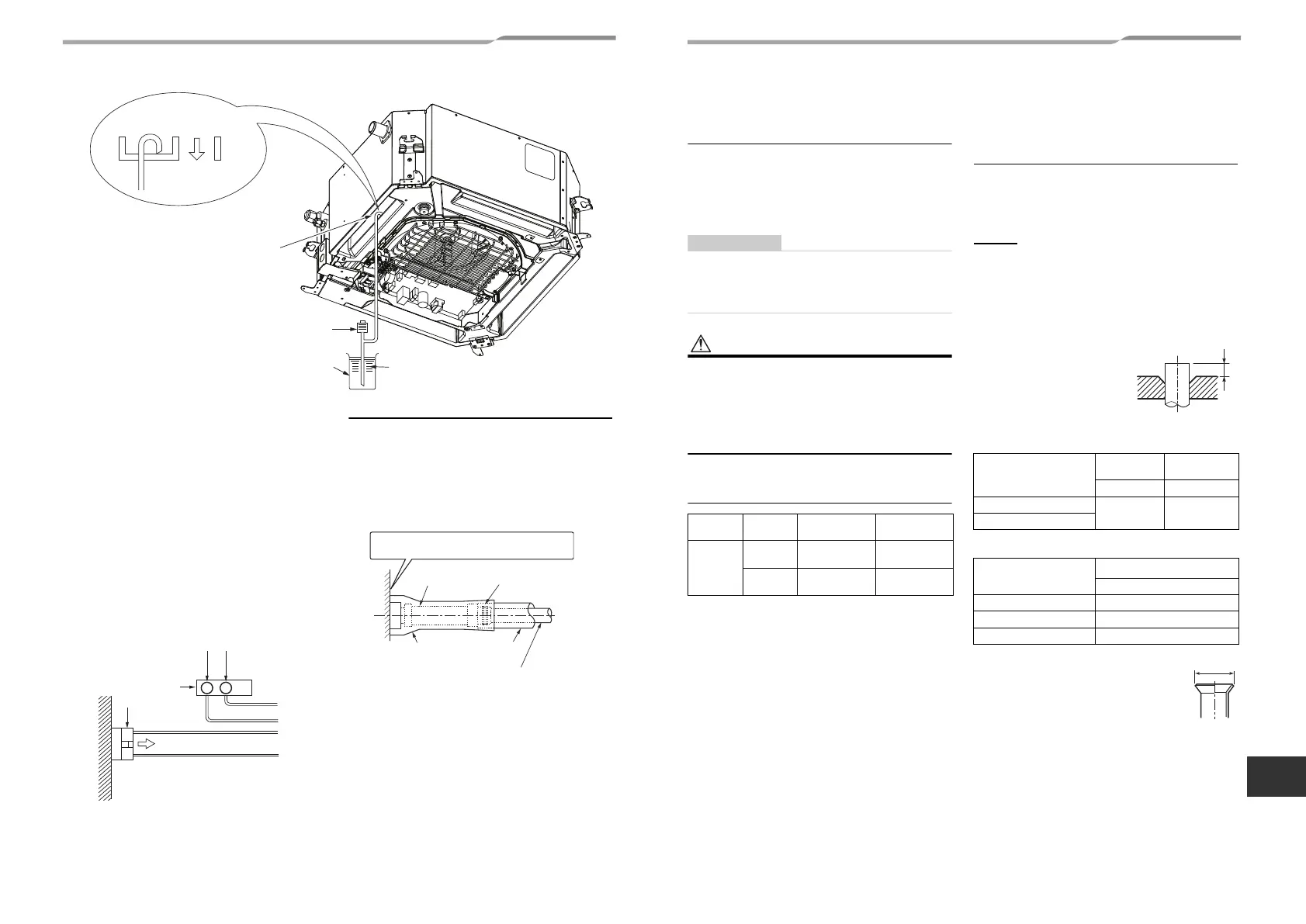

6 Refrigerant piping and evacuation

Refrigerant piping

1. Use copper pipe with 0.03” (0.8 mm) or more

thickness.

2. Flare nut and flare works are also different from

those of the conventional refrigerant.

Take out the flare nut attached to the main unit of the

air conditioner, and use it.

When the refrigerant pipe is long, provide support

brackets at intervals of 8’2” - 9’10” (2.5 - 3 m) to clamp

the refrigerant pipe. Otherwise, abnormal sound may be

generated.

IMPORTANT 4 POINTS FOR PIPING WORK

1. Remove dust and moisture from the inside of the

connecting pipes.

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes by using

VACUUM PUMP.

4. Check the gas leakage. (Connected points)

Pipe size

Permissible piping length and

height difference

They vary according to the outdoor unit.

For details, refer to the Installation Manual attached to

the outdoor unit.

Flaring

• Cut the pipe with a pipe cutter.

Remove burrs completely.

Remaining burrs may cause gas leakage.

• Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly manufactured

for R410A are recommended.

However, the conventional

tools can be used by adjusting

projection margin of the

copper pipe.

▼ Projection margin in

flaring: B (Unit: in (mm))

Rigid (Clutch type)

▼ Flaring dia. meter size: A (Unit: in (mm))

* In case of flaring for R410A with the

conventional flare tool, pull it out approx.

0.02" (0.5 mm) more than that for R22 to

adjust to the specified flare size.

The copper pipe gauge is useful for

adjusting projection margin size.

Model

name

MMU-

AP007, AP009,

AP012 type

AP015, AP018

type

Pipe size

Gas side

3/8”

(9.5 mm)

1/2”

(12.7 mm)

Liquid side

1/4”

(6.4 mm)

1/4”

(6.4 mm)

Outer dia. of copper pipe

R410A tool

used

Conventional

tool used

R410A R410A

1/4” (6.4), 3/8” (9.5)

0 - 0.02”

(0 - 0.5)

0.04” - 0.06”

(1.0 - 1.5)

1/2” (12.7)

Outer dia. of copper pipe

A

+0

–0.02 (0.4)

R410A

1/4” (6.4) 0.36” (9.1)

3/8” (9.5) 0.52” (13.2)

1/2” (12.7) 0.65” (16.6)

15-EN 16-EN

+00EH99876101-2_00Ta.book Page 8 Monday, September 1, 2014 10:15 AM

Loading...

Loading...