Machine Operators can operate the machine solely by using the controls available on

remains strictly forbidden due to the presence of energized and hot parts.

Machine Operators can operate the machine solely by using the controls available on

s to the inside of the Control switch

remains strictly forbidden due to the presence of energized and hot parts.

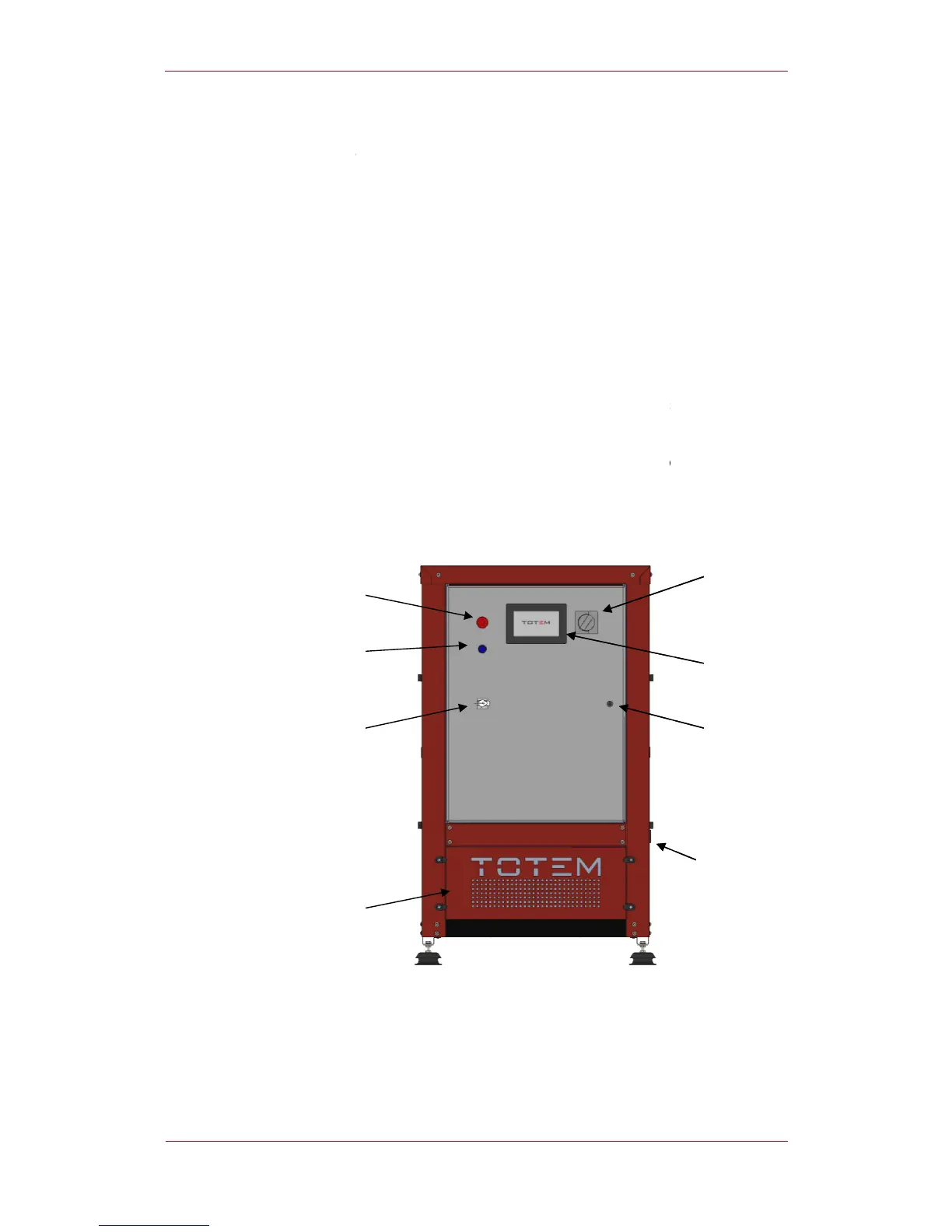

oard features the following control devices:

Main Switch (A): by operating the Main Switch

supply is interrupted and the unit i

s disconnected from the power grid

Emergency pushbutton (B):

in the event of an emergency, the unit can

be switched off by pressing the emergency pushbutton;

Emergency relay manual reset pushbutton (C):

off by means of the emergency pushbutton or following activation of

one of the alarms along the safety chain (high temperature or methane

leak) , the emergency relay must be manually reset by pressing the

reset button before restarting the unit;

Operator Panel (D): it consists of a LCD

displays all the unit’s operating info and enabling operators to enter all

LAN connection (E): the LAN port enables con

providing access the operator panel.

A: Main Switch

B: Emergency Pushbutton

C: Emergency Relay Manual Reset Button

D: Operator Panel

E: LAN connection

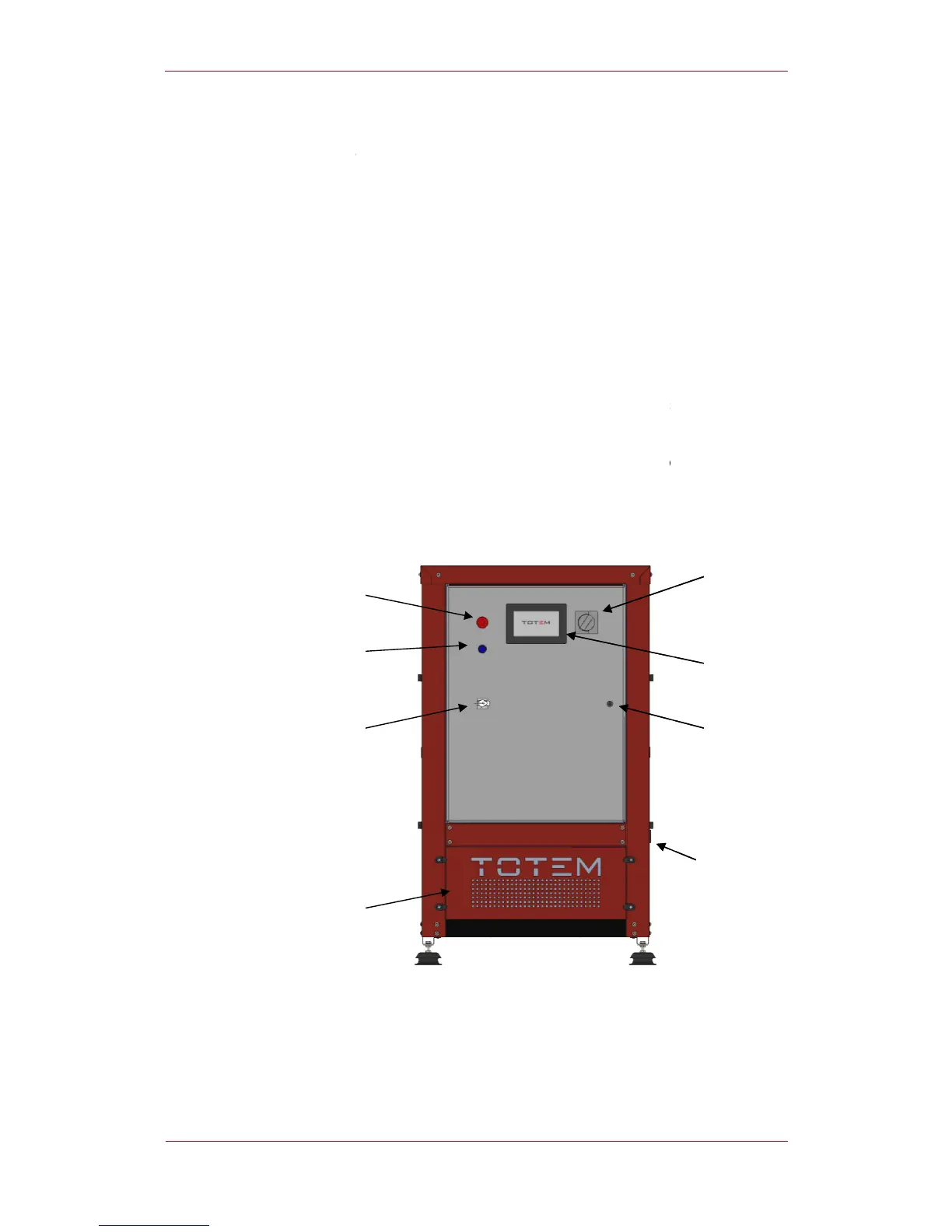

Machine Operators can operate the machine solely by using the controls available on

s to the inside of the Control switch

remains strictly forbidden due to the presence of energized and hot parts.

s disconnected from the power grid

in the event of an emergency, the unit can

be switched off by pressing the emergency pushbutton;

off by means of the emergency pushbutton or following activation of

one of the alarms along the safety chain (high temperature or methane

leak) , the emergency relay must be manually reset by pressing the

displays all the unit’s operating info and enabling operators to enter all

Loading...

Loading...