10 18-AC115D1-1B-EN

STEP 3 - Purge the refrigerant lines and indoor

coil with dry nitrogen.

STEP 4 - Wrap a wet rag around the valve body to

avoid heat damage and continue the dry nitrogen

purge.

Braze the refrigerant lines to the service valves.

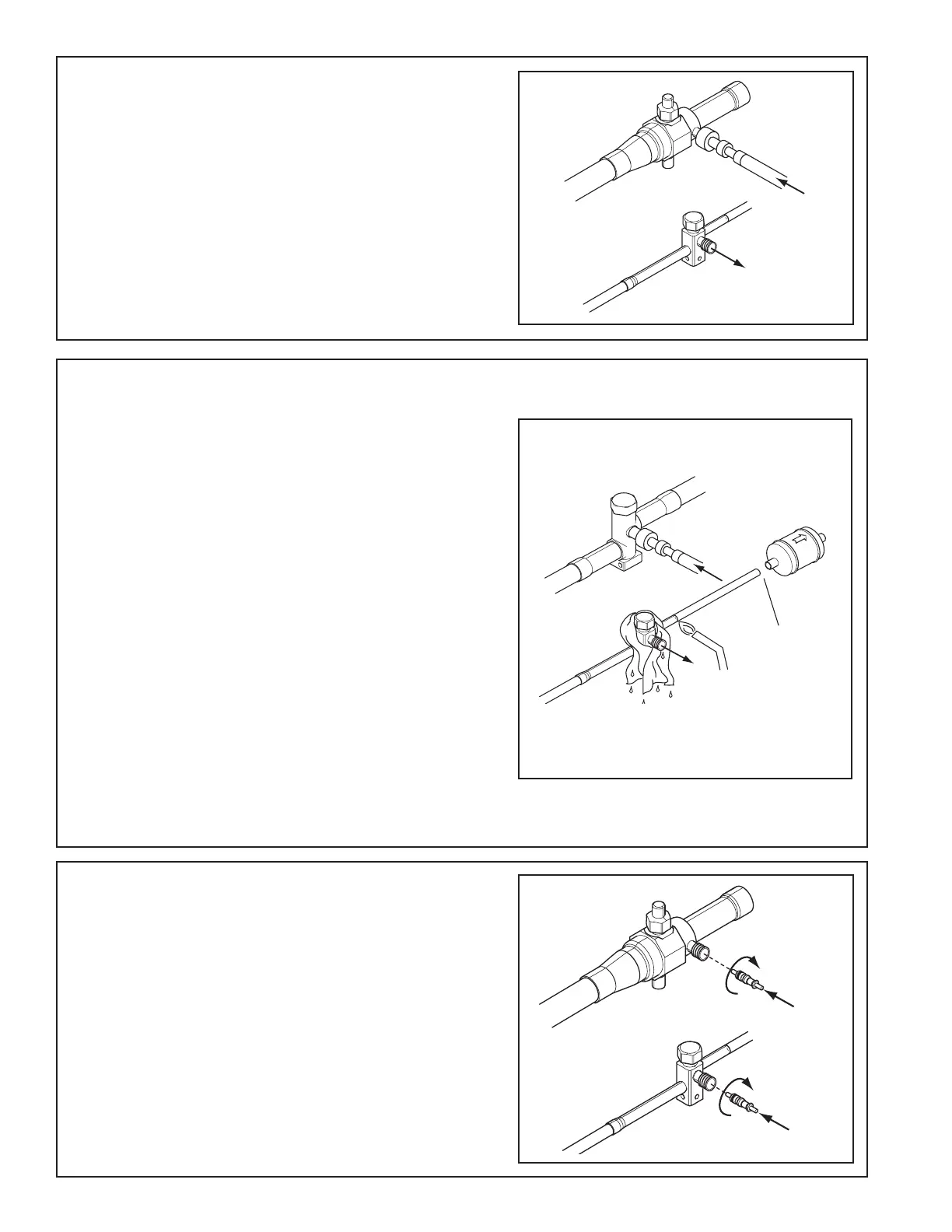

For units shipped with a field-installed external

drier, check liquid line filter drier’s directional flow

arrow to confirm correct direction of refrigeration

flow (away from outdoor unit and toward evapora-

tor coil) as illustrated. Braze the filter drier to the

Liquid Line.

Continue the dry nitrogen purge. Do not remove

the wet rag until all brazing is completed.

Important: Remove the wet rag before stopping

the dry nitrogen purge.

Note: Install drier in Liquid Line.

NOTE:NOTE: Precautions should be taken to avoid Precautions should be taken to avoid

heat damage to basepan during brazing. It is heat damage to basepan during brazing. It is

recommended to keep the flame directly off of the recommended to keep the flame directly off of the

basepan.basepan.

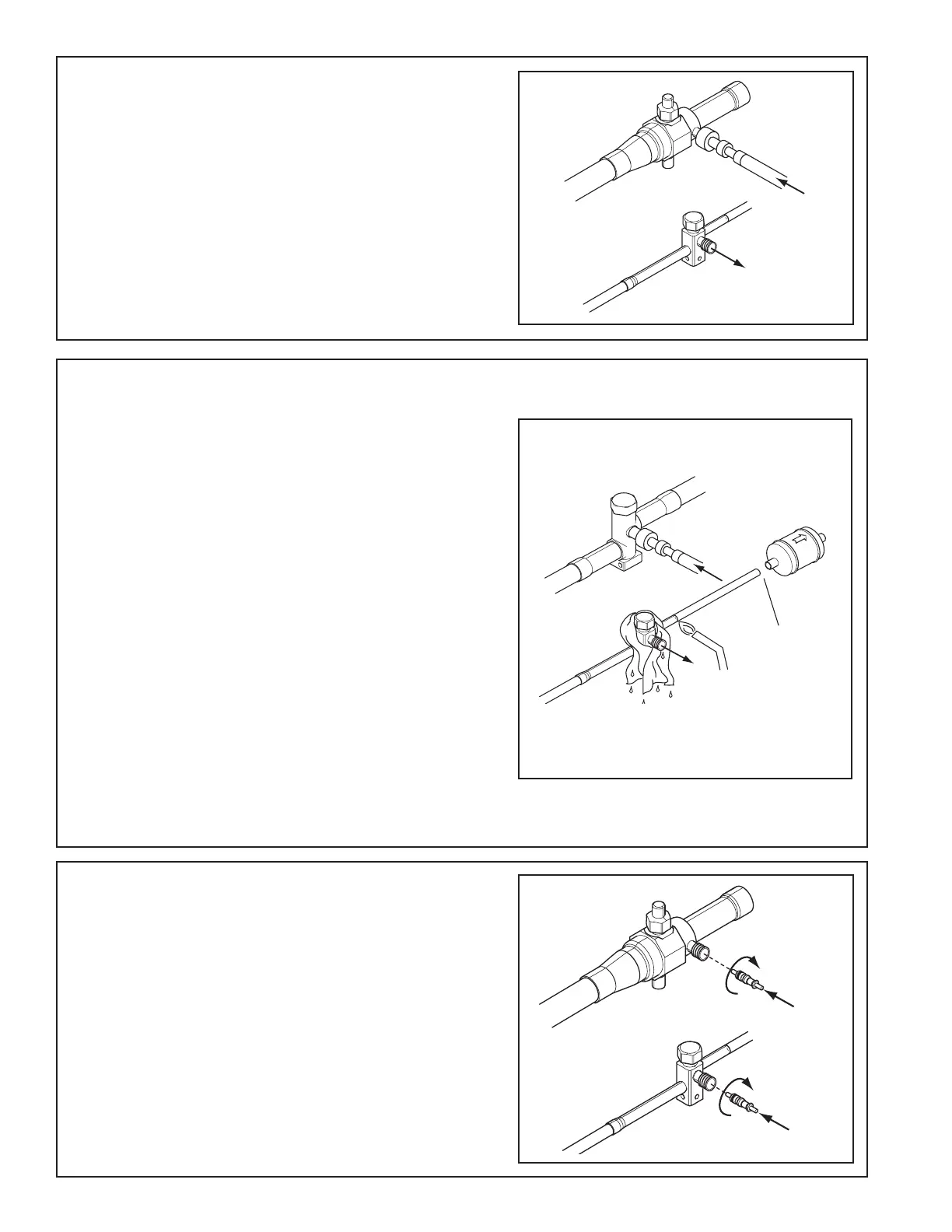

STEP 5 - Replace the pressure tap valve cores

after the service valves have cooled.

Loading...

Loading...