19

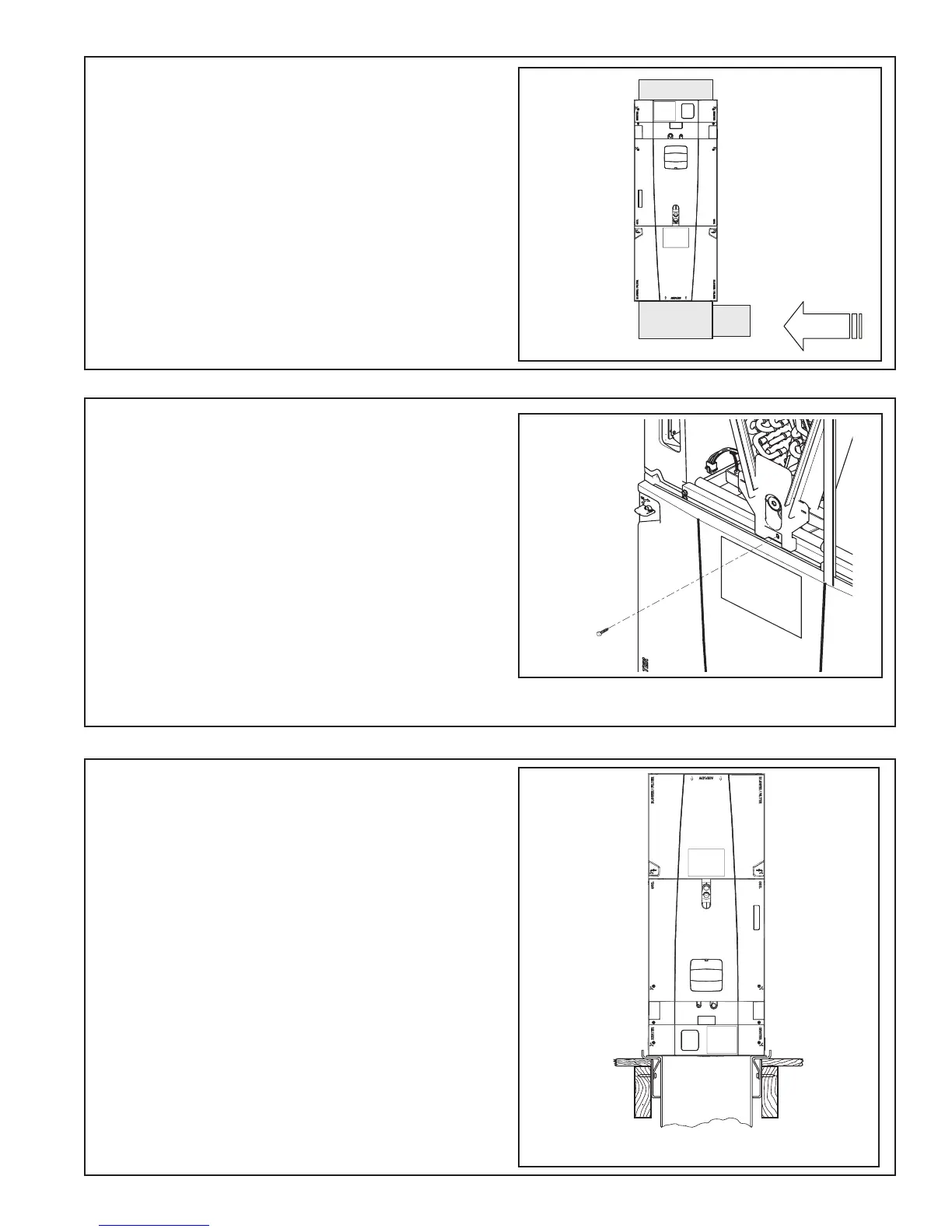

Plenum Installation

1. Assemble the plenum using the plenum’s

Installer Guide.

Airflow

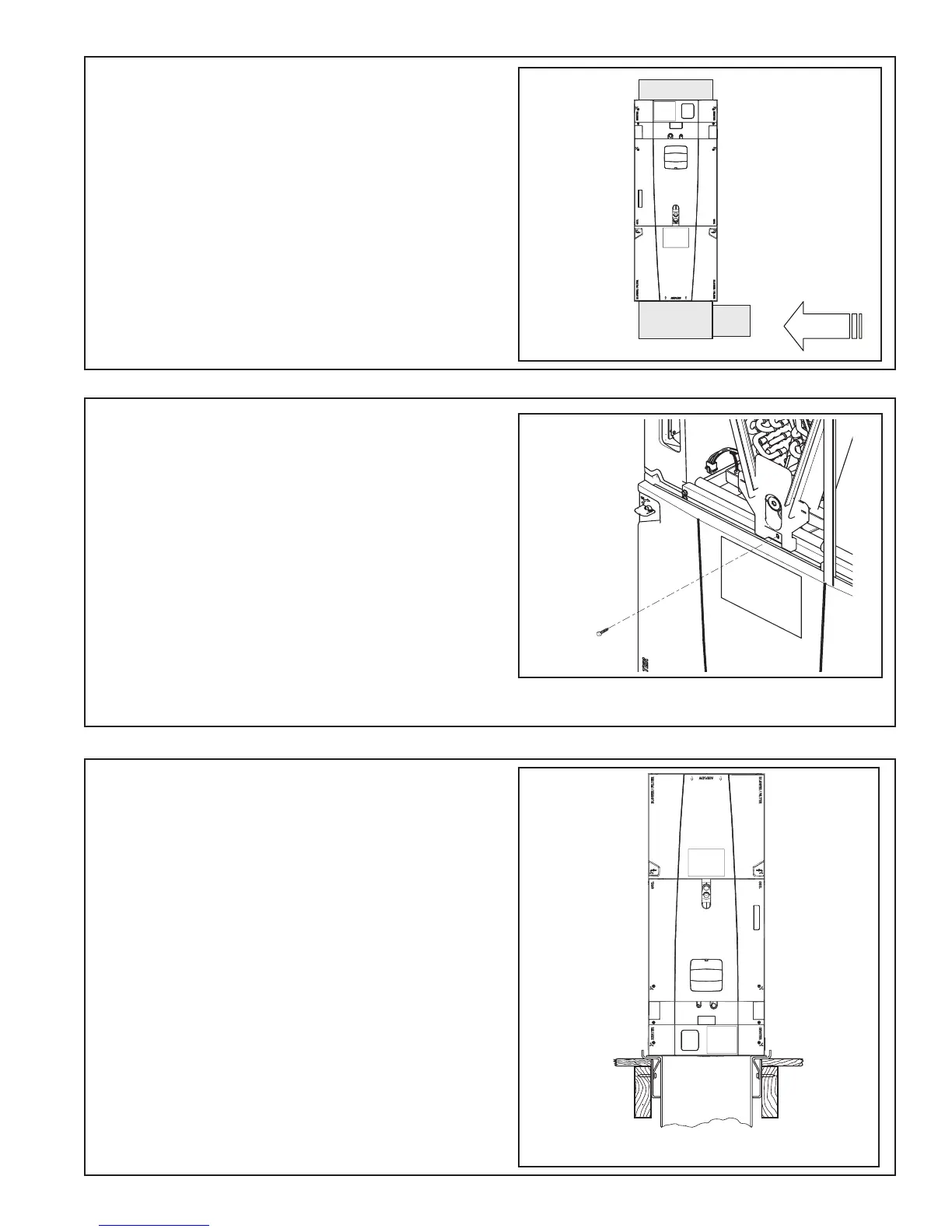

7.5 Downflow Installation

• Downflow installation must comply with national,

state, and local codes.

• The air handlers are rated for zero clearance from

combustible materials.

STEP 1 - Prepare the location site as appropriate for

your application and per national, state, and local code

requirements.

STEP 2 - Set the unit in position.

Representative Illustration

Typical Downflow Installation

On units with sheet metal returns: Return plenum

must be flanged. Sheet metal drill point screws

must be 1/2” in length or shorter.

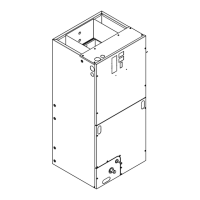

7.4 Secure Coil (Downflow Applications)

STEP 1 - Remove Coil Panel.

STEP 2 - Remove screw from documentation packet.

STEP 3 - While the air handler is in the upflow posi-

tion, use the supplied screw to secure the coil seal

plate to cross member as shown.

Important: The Coil Seal Plate and screw secure the

coil in the center of the air handler. Failure to follow

these steps can prevent the Coil Panel from being

easily replaced on the unit.

Important: For the 5 ton air handler model

*AM4A0C60S51SA, tap 5 should not be used in the

downflow or horizontal orientations. Using Tap 5

could result in water blowing off the coil.

Typical Plenum Installation

Important: Ensure EEV sensor and motor wiring

are taught and wire-tied to the distributor tube to

prevent damage during electric heat operation.

Loading...

Loading...