2 88-A4AH4TXV-1C-EN

COIL THERMAL EXPANSION VALVE INSTALLER'S GUIDE

Installation Instructions

1. If air handler has never been installed, go to Step 2.

If air handler has been previously installed, recover

system charge or “pump-down” system charge into

the condensing unit to comply with EPA regulations.

NOTE: Minimize the amount of movement of the liquid

and distributor tubes to prevent work hardening.

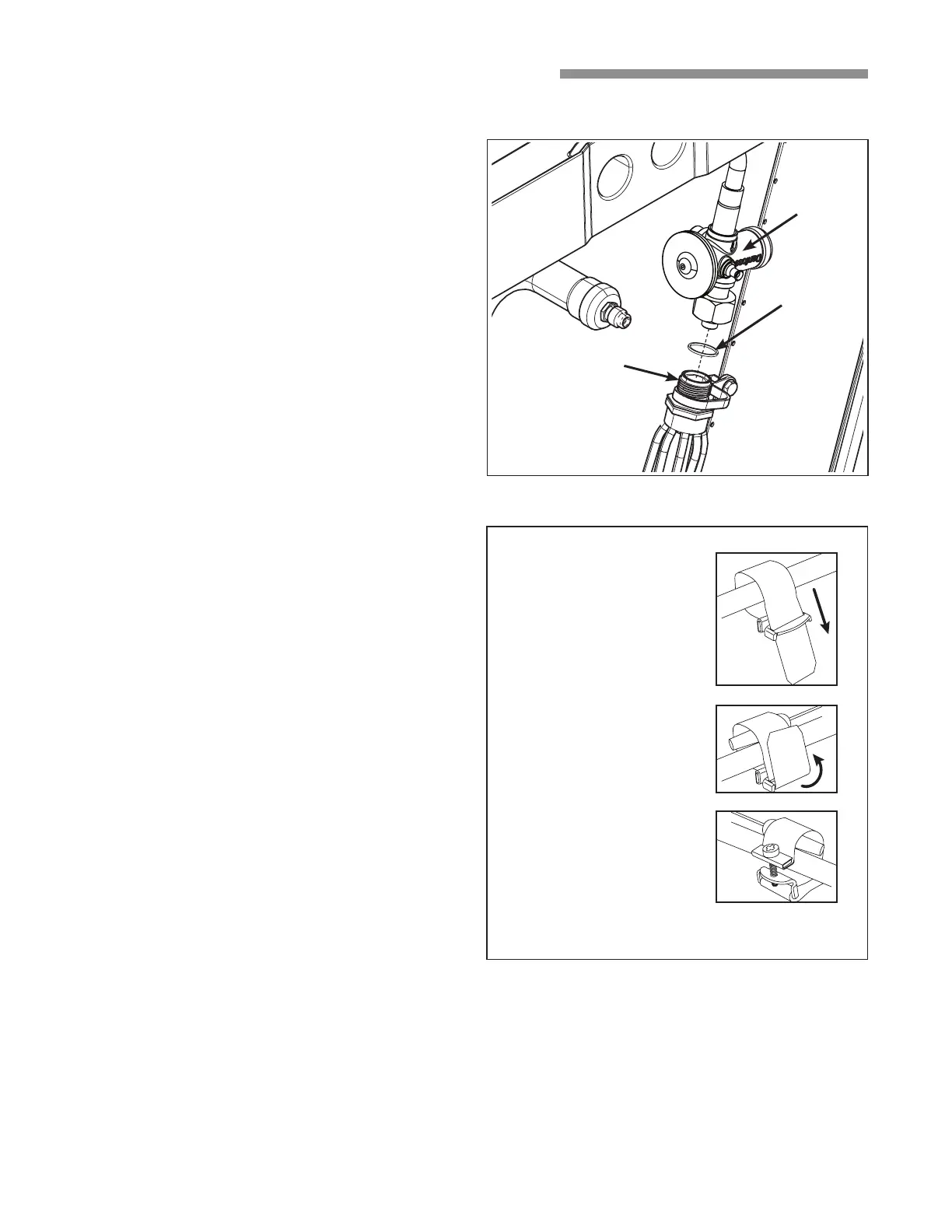

2. Using a back-up wrench, loosen mechanical fittings

on the orifice housing of the distributor.

3. Remove the cap from the equalizer port and then

REMOVE the Schrader valve from the port.

4. Remove the Teflon

®

O-ring from the existing flow

control assembly. O-rings may be attached to the

TXV or the fittings.

IMPORTANT: Proper installation of TXV is critical for

preventing leaks. DO NOT oil any threads on TXV,

distributor, or liquid line ttings.

5. To install the coil TXV, install the new O-ring over the

distributor fitting (Figure 2). Hand-tighten the nut to

make sure there is proper mating of threads. Tighten

until bodies “bottom” or a definite resistance is felt.

Use a back-up wrench and tighten an additional 1/4

turn. Wrap supplied push-in cable tie around TXV

and then insert cable tie barb into coil housing hole.

IMPORTANT: Correct tightening of the nut is very

important. Under- or over-tightening may result in a

leaking connection.

6. Connect the TXV equalizer line to the equalizer

port. Hand-tighten until flare bottoms. Use a back-

up wrench to tighten securely (Figure 4).

IMPORTANT: Replacing the liquid line lter drier is

recommended if system has been commissioned. This

is not necessary if this kit is being installed on a new air

handler.

7. To avoid damaging the TXV, braze the field gas line

to the air handler gas manifold prior to attaching the

TXV bulb.

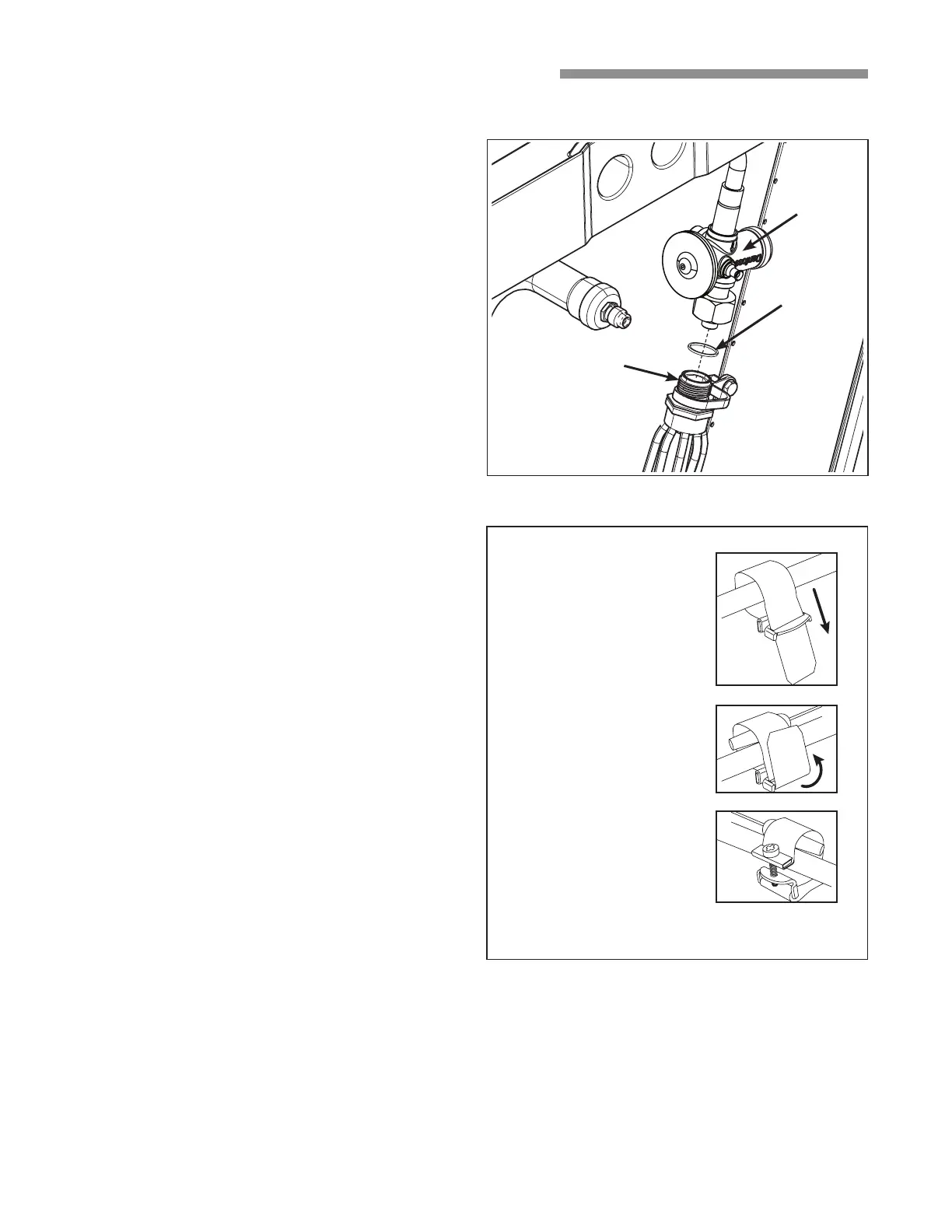

8. After completing the brazing operation, allow the

lines to cool. Attach the bulb to the gas line as

shown in figure 3.

Distributor

Fitting

Figure 2

Teon®

O-ring

TXV

Make contact tight.

• Clean the suction line

thoroughly before

clamping the bulb in

place.

• Bulb has to be mounted

in tight contact with pipe.

(TIP: Shine a flashlight

between bulb and suc-

tion line, realign the bulb

if light is visible.)

• Align the bulb with cop-

per gas line and position

at 10 or 2 o’clock.

• Pull the bulb strap tight

around the copper gas

line and bulb before

tightening the screw.

• After tightening, it should

not be possible to move

the bulb by hand.

Figure 3

Loading...

Loading...