40

CVHE-SVX02M-EN

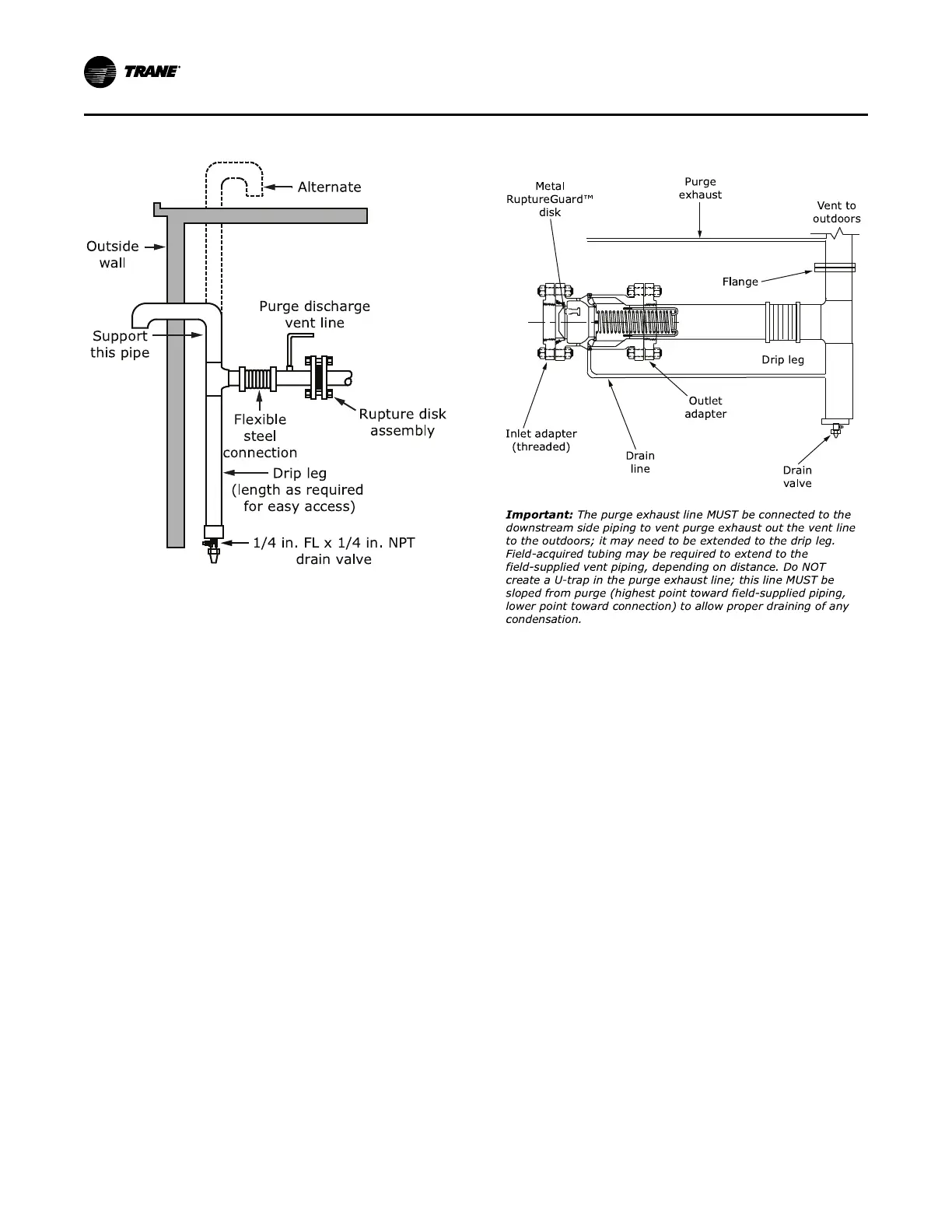

Figure 25. Arrangement for rupture disk relief piping

IImmppoorrttaanntt:: On the purge discharge vent line, the purge

exhaust connection point MUST be lower

than the purge height. Do NOT create a U-

trap; extend to drip leg if necessary to

avoid a trap.

NNootteess::

• If a RuptureGuard

™

is to be installed,

remove and discard the factory-installed

rupture disk; for more information, refer to

Installation, Operation, and Maintenance:

RuptureGuard Pressure Relief System

Option (CTV-SVX06*-EN).

• The rated flow capacity of the

RuptureGuard

™

disk/valve assembly is

based on having straight pipe extending

past the spring mechanism downstream of

the valve. Be sure there are no crosses (a

derate on the rated flow capacity for this

configuration is published in Engineering

Bulletin: RuptureGuard Selection Guide [E/

CTV-EB-10]), elbows, tees or any other

obstructions within the first 9 in. (228.6 mm)

of valve discharge. Refer to ASHRAE

Standard 15 for additional requirements on

piping rupture disk and relief valve vent

lines.

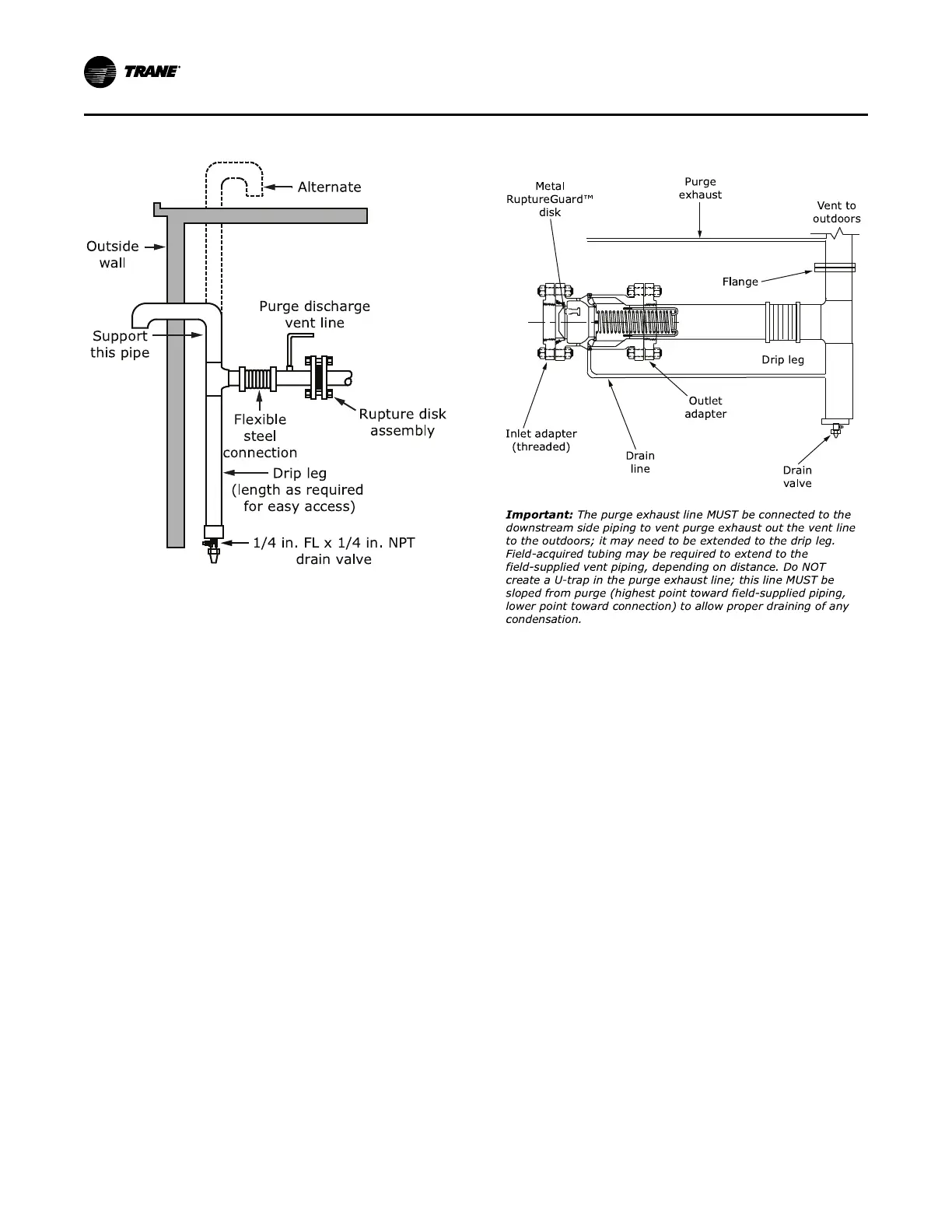

Figure 26. RuptureGuard™™ external vent line and

drip leg (not provided)

NNootteess::

• Use Loctite

®

242 or Loctite

®

277 on all

threaded joints on chillers charged with

refrigerant; use of other pipe thread sealants

is NOT recommended. Ensure all threaded

pipe joints are properly cleaned and

prepared before assembly. An alternative to

the use of Loctite

®

is to thread and weld the

inlet adapter to the pipe. Care must be taken

to ensure that the flange mating surface

remains flat. Do NOT weld on the Inlet

Adapter flange while connected to the

RuptureGuard

™

.

• The drip leg is required and must be drained

periodically for proper chiller purge

operation.

IImmppoorrttaanntt:: If a RuptureGuard

™

is to be installed, it

MUST be installed properly. Failure to

properly install RuptureGuard

™

will likely

result in a start-up delays and required

rework and expenses that result from a

failure to properly install RuptureGuard

™

will NOT be paid by Trane.

VVeenntt PPiippiinngg

Loading...

Loading...