RT-SVX059D-EN 21

Maintenance

Make sure all personnel are standing clear of the unit

before proceeding. The system components will start

when the power is applied.

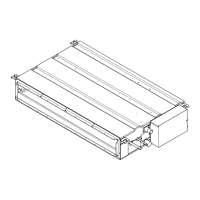

Fan Belt Adjustment—Belt Drive

Units

WARNING

Rotating Components!

The following procedure involves working with rotating

components. Disconnect all electric power, including

remote disconnects before servicing. Follow proper

lockout/tagout procedures to ensure the power can not

be inadvertently energized. Failure to disconnect power

before servicing could result in rotating components

cutting and slashing technician which could result in

death or serious injury.

The fan belts must be inspected periodically to assure

pr

oper unit operation.

Replacement is necessary if the belts appear frayed or

worn. Units with dual

belts require a matched set of belts

to ensure equal belt length.

When removing or installing the new belts, do not stretch

them

over the sheaves. Loosen the belts using the belt

tension adjustment bolts on the motor mounting base.

Once the new belts are installed, using a Browning or

G

ates tension gauge (or equivalent) illustrated in

Figure 12; adjust the belt tension as follows;

1. To determine the appropriate belt deflection;

a. Measure the center-to-center shaft distance (in

in

ches) between the fan and motor sheaves.

b. Divide the distance measured in Step 1a by 64; the

r

esulting value represents the amount of belt

deflection that corresponds to the proper belt

tension.

2. Set the large O-ring on the belt tension gauge at the

de

flection value determined in Step 1b.

3. Set the small O-ring at zero on the force scale of the

ga

uge plunger.

4. Place the large end of the gauge at the center of the belt

spa

n; then depress the gauge plunger until the large

O-ring is even with the top of the next belt or even with

a straightedge placed across the fan and motor

sheaves.

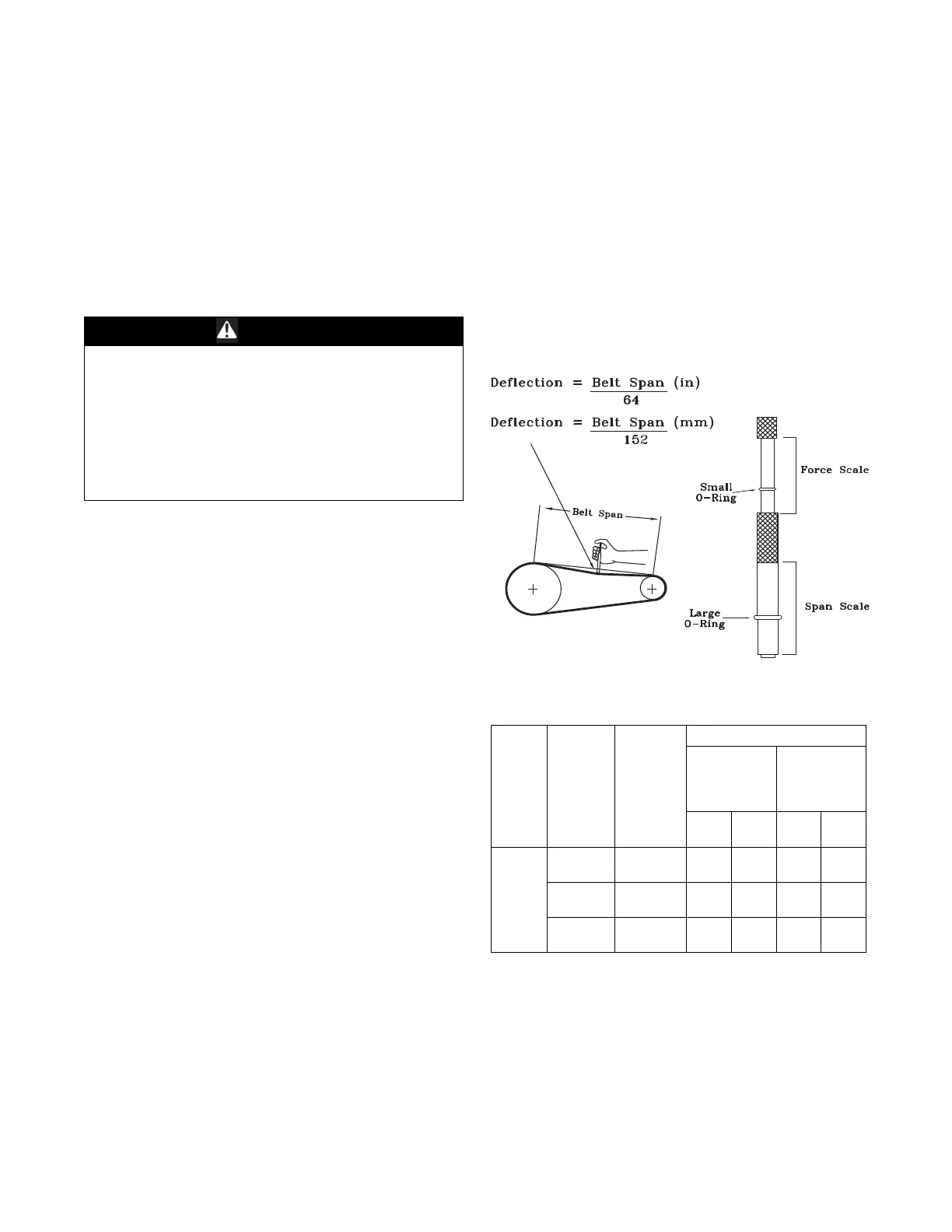

Refer to Table 5, p. 21.

5. Remove the belt tension gauge. The small O-ring now

in

dicates a number other than zero on the plunger’s

force scale. This number represents the force (in

pounds) required to give the needed deflection.

6. Compare the “force” scale reading (Step 5) with the

appropriate “force” value listed in Table 5, p. 21. If the

“f

orce” reading is outside the range, readjust the belt

tension.

Note: Actual belt deflection “force

” must not exceed the

maximum “force” value shown in Table 5, p. 21.

7. Recheck the belt tension at least twice during the first

2

to 3 days of operation. Belt tension may decrease

until the new belts are “run in”.

Figure 12. Belt tension gauge

Table 5. Belt tension measurement and deflection

ranges

Belts

Cross

Section

Smallest

Sheave

Diameter

Range

(in.)

RPM

Range

Deflection Force (lb)

Super

Gripbelts and

Unnotched

Gripbands

Gripnotch

Belts and

Notched

Gripbands

Used

Belt

New

Belt

Used

Belt

New

Belt

A, AX

3.0–3.6

1000-2500

2501-4000

3.7

2.8

5.5

4.2

4.1

3.4

6.1

5.0

3.8–4.8

1000-2500

2501-4000

4.5

3.8

6.8

5.7

5.0

4.3

7.4

6.4

5.0–7.0

1000-2500

2501-4000

5.4

4.7

8.0

7.0

5.7

5.1

8.4

7.6

Loading...

Loading...