Operating Procedures

ARTC-SVX005A-EN 47

11. Verify that pressure switches and thermostats have the

correct cut-in and cut-out settings using the

touchscreen interface panel.

Emergency Power Shutdown

The chiller does not include a disconnect to turn off the

high voltage to the modules. As per NFPA 70, The National

Electrical Code, a disconnect must be installed within the

line of sight of the electrical and control panel. Should an

emergency condition arise, the disconnect must be

opened to shut down all voltage to the chiller/heater.

There are several ways to interrupt power to all or part of

the chiller/heater:

• Disconnect the primary power source from the

building that feeds electricity to the chiller/heater.

This occurs in sudden emergencies (usually

weather-related) or planned maintenance shut-

downs.

• Press the panel disconnect switch on the exterior

door of the chiller/heater’s main power distribution

panel, if so equipped.

• Move the circuit breaker switch to the OFF position

(CB-1 and CB-2) on the power distribution panel.

This cuts power to all of the chiller/heater modules.

• Move the circuit breaker switch to the OFF position

(CB-1 and CB-2) on a module’s electrical and control

panel. This cuts power to the compressors in a

single module. It does not cut power to electrical

and control panel or other chiller/heater modules.

• Press the SYSTEM ON button on the touchscreen

interface panel that is built into the power

distribution panel door.

Note: Pressing the SYSTEM ON button on the

touchscreen interface panel does not de-energize

the chiller or the high voltage current into each

module’s electrical and control panel. This action

sends a command to the controller in each

module’s compressors to discontinue electrical

current to that component.

Water Quality Guidelines

The chiller is equipped with high efficiency compact

brazed plate heat exchangers (BPHX). Water quality must

be maintained periodically by the end user to avoid scaling

and corrosion inside the heat exchangers.

Monitor Water Quality

Maintaining water/glycol mixture quality and cleanliness

is critical to chiller/heater health and maintainability.

Strainers should be checked and cleaned on a regular

basis. Water/glycol mixture samples should be taken and

tested by a professional lab. The results will enable the

accurate adjustment of quality thereby increasing the

operational life of the chiller/heater.

Note: Trane will not validate the chiller warranty if the

proper water/glycol mixture composition and

quality is not maintained.

Protect the chiller/heater from freezing, particularly if the

chiller has a set point that is lower than the freezing point

of the water/glycol mixture in the chiller/heater. The chiller/

heater is designed to operate with a maximum propylene

glycol concentration of 50%. See Table 10, p. 48, for the

effects on the chiller when operating with other glycol

concentrations.

Table 10, p. 48 shows the capacity reduction and the

pressure drop that occurs when higher concentrations of

glycol are used.

Maintain Glycol Level

When the chiller has a water set point that is below the

freezing point of the water/glycol in use, take precautions

against freezing.

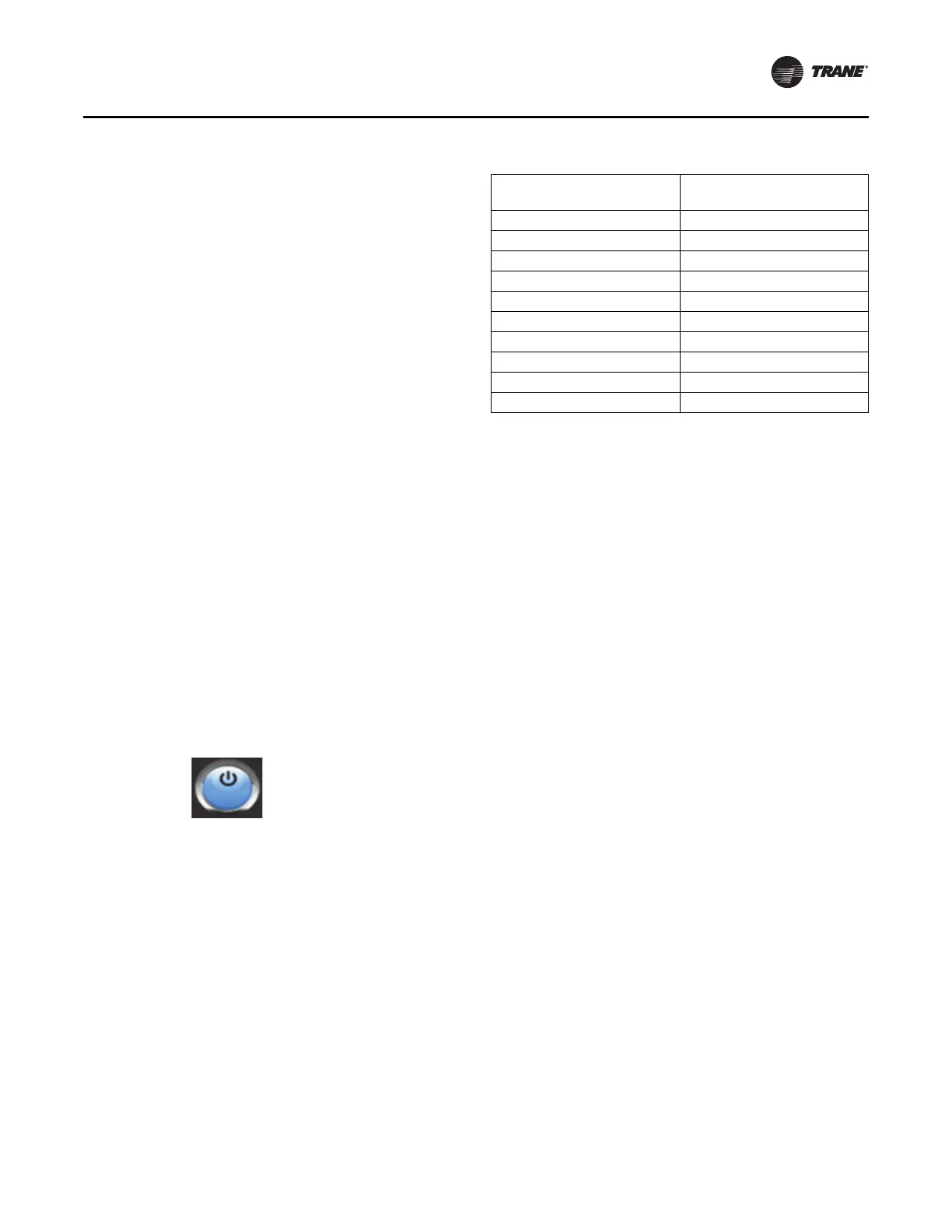

Table 9. Water quality guidelines

Element /Compound/

Property Value/Unit

pH 7.5 - 9.0

Conductivity < 500 μS/cm

Total Hardness 4.5 - 8.5 dH°

Free Chlorine < 1.0 ppm

Ammonia (NH

3

) < 0.5 ppm

Sulphate (SO

4

2-

) < 100 ppm

Hydrogen Carbonate (HCO

3-

) 60 – 200 ppm

(HCO

3-

) / (SO

4

2-

)> 1.5

(Ca + Mg) / (HCO

3-

)> 0.5

Chloride (Cl-) < 200 ppm

Notes:

1. Total Hardness/corrosion: Water with high hardness can cause

corrosion problems due to its high ion content (Ca+2, Mg+2, Fe+2)

which also means a high electrical conductivity and a high total

dissolved solid (TDS). For this reason, too high hardness values

should be avoided, not only due to higher risk of scaling, but also for

corrosion risk.

On the other hand, soft water, but not necessarily cation exchange

softened water, may in contrast have a low buffering capacity and so

be more corrosive. If the hardness values are outside the

recommended range, other parameters such as oxygen content,

conductivity, and pH values should be considered to evaluate the

corrosion risk.

2. Fe3+ and Mn4+ are strong oxidants and may increase the risk for

localized corrosion on stainless steels in combination with brazing

material copper.

Loading...

Loading...