RT-SVX075C-EN

39

Figure 59. Wireless communication interface -

horizontal

Note: Cable ties must be removed to allow the cable to

extend to the horizontal mounting location.

Main Electrical Power

Requirements

WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious

injury.

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by

Trane or others, refer to the appropriate

manufacturer’s literature for allowable waiting periods

for discharge of capacitors. Verify with a CAT III or IV

voltmeter rated per NFPA 70E that all capacitors have

discharged.

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury.

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements

for field wiring installation and grounding as

described in NEC and your local/state/national

electrical codes.

1. Verify that the power supply complies with the unit

nameplate specifications.

2. Inspect all control panel components and tighten any

loose connections.

3. Connect properly sized and protected power supply

wiring to a field-supplied/installed disconnect switch

and to the main power terminal block (HTB1) in the unit

control panel.

4. Install proper grounding wires to an earth ground.

Through-the-Base Gas

Installation

Important: All phases of this installation must comply with

national, state, and local codes. In absence of

local codes, the installation must conform with

American National Standard-Z223.1a-

National Fuel Gas Code Latest Revision.

Note: For complete Gas Heat User information, Operation,

Start-up, Shutdown and Maintenance refer to “Gas

Heat Operation and Maintenance,” p. 68.

1. Remove the access panel for the heat section on the

front of the unit for field connections.

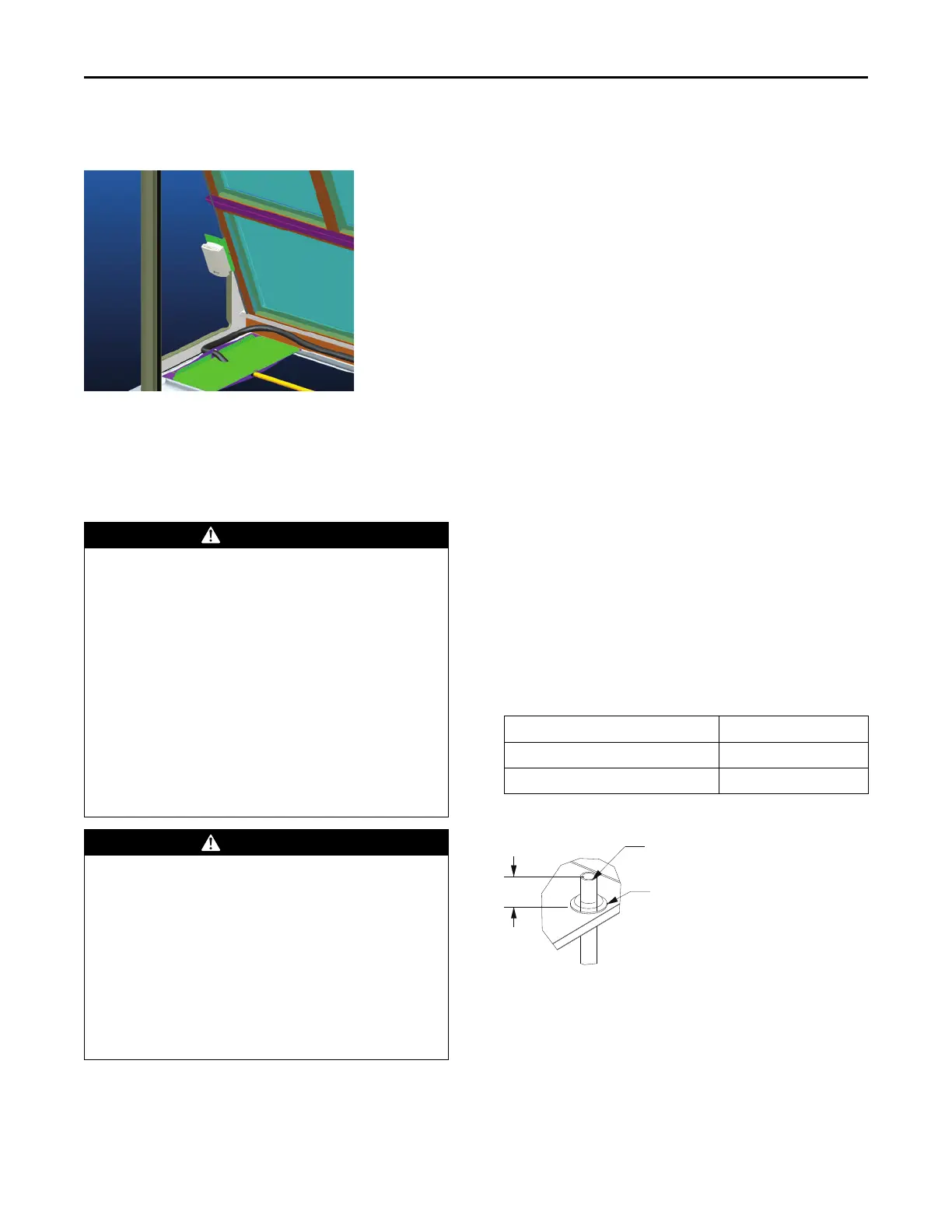

2. The gas piping assembly ships inside this section and

includes the shut-off valve, a pressure tap for testing,

and the necessary unions for field connection. For

through the base access, remove the factory-provided

cap from the base pan opening. See Figure 60, p. 39

and Figure 61, p. 40.

3. Route field piping through this hole to the dimension

shown in Table 5, p. 39.

4. Place the assembly through the cabinet opening shown

in Figure 61, p. 40 and make the union connection to

the field piping and to the gas train.

Table 5. Through-the-base gas piping dimension

Model

Dimension A (inch)

YHJ(072-150)***(0,A) (L, M, H)

4 5/8

YHJ(180-300)***(0,A)(L, M, H)

1 3/16

Figure 60. Through-the-base gas pipe height

A

Customer Gas Supply Pipe

Grommet

DETAIL A

Installation

Loading...

Loading...