Pre-Start

42 RT-SVX46G-EN

Test Modes

There are three methods in which the “Test” mode can be

cycled at LTB-Test 1 and LTB-Test 2.

1. Step Test Mode - This method initiates the different

com

po

nents of the unit, one at a time, by temporarily

shorting across the two test terminals for two to three

seconds. For the initial startup of the unit, this method

allows the technician to cycle a component “On” and

have up to one hour to complete the check.

2. Resistance Test Mode - This method can be used for

startu

p prov

iding a decade box for variable resistance

outputs is available. This method initiates the different

components of the unit, one at a time, when a specific

resistance value is placed across the two test

terminals. The unit will remain in the specific test mode

for approximately one hour even though the

resistance is left on the test terminals.

3. Auto Test Mode - This method is not recommended

for

startup du

e to the short timing between individual

component steps. This method initiates the different

components of the unit, one at a time, when a jumper

is installed across the test terminals. The unit will start

the first test step and change to the next step every 30

seconds.

At the end of the test mode, con

trol of the unit will

automatically revert to the applied “System” control

method.

For unit test steps, test modes, and step resistan

ce valu

es

to cycle the various components, refer to Table 9, p. 42.

ReliaTel™ Controls

Upon power initialization, the Gas Ignition Module (IGN)

performs self-diagnostic checks to insure that all internal

controls are functional. It also checks the configuration

parameters against the components connected to the

system. The System LED located on the IGN module is

turned “On” within one second of power-up if internal

operation is okay.

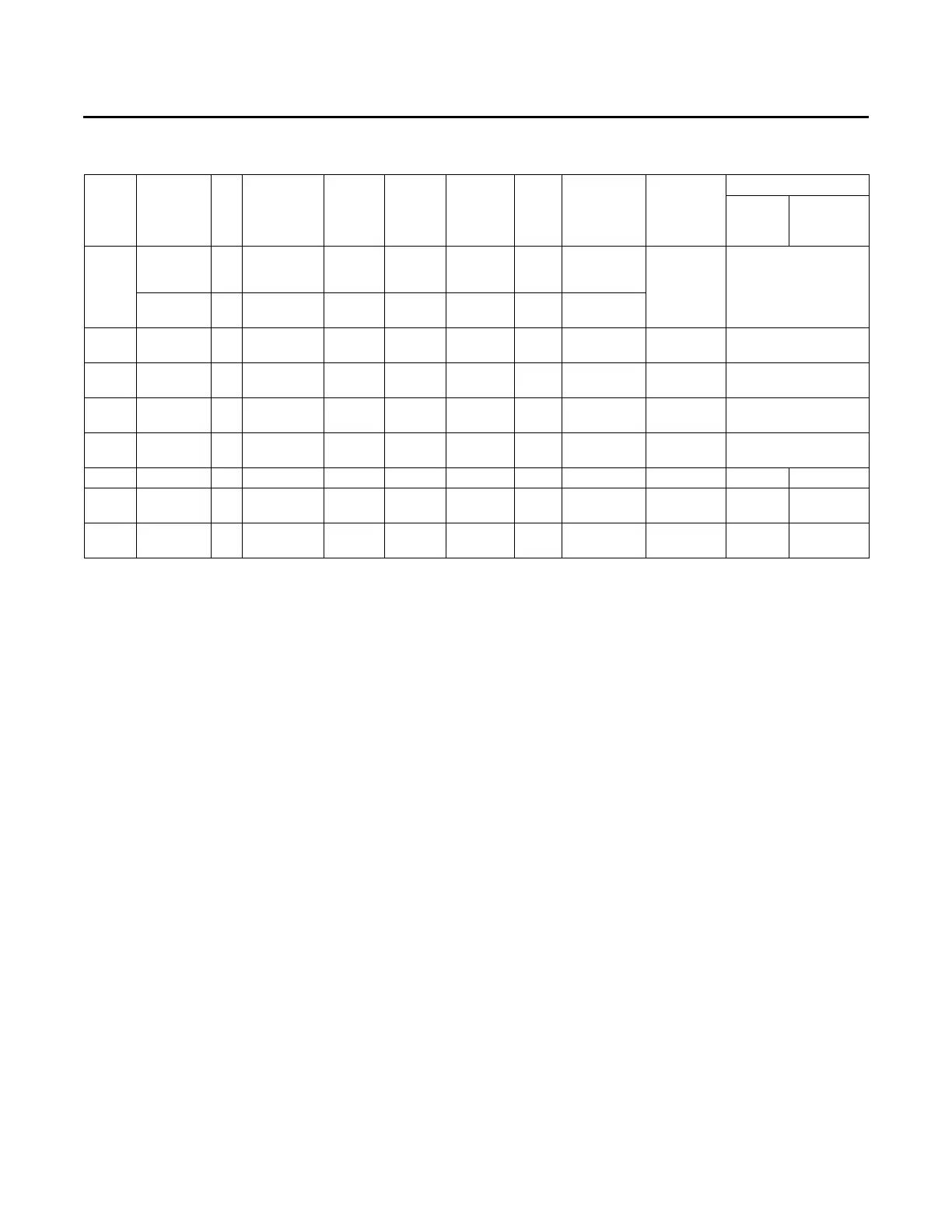

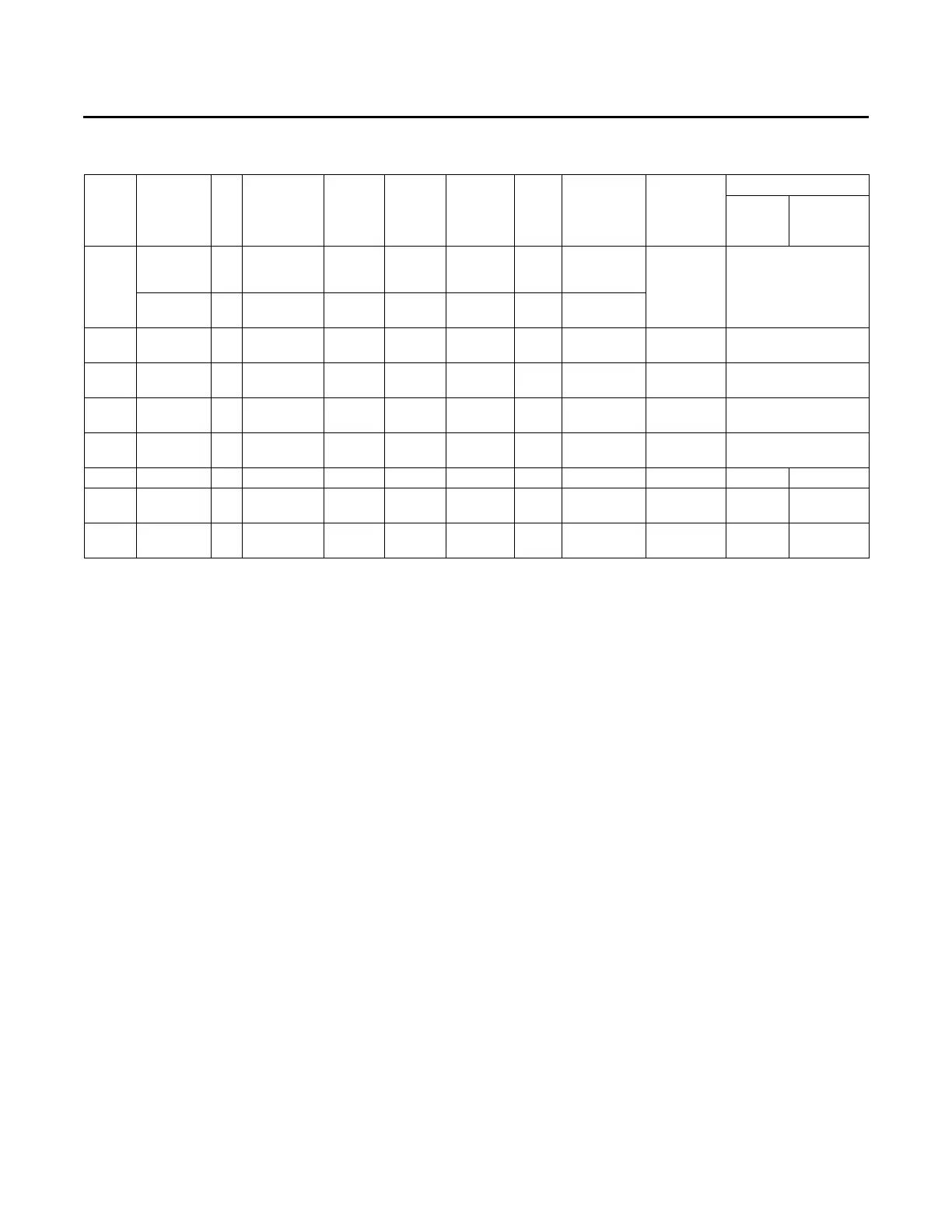

Table 9. Service test guide for component operation

Test

Step

Mode Fan Econ

(a)

Comp 1 Comp 2 Heat 1 Heat 2

Modulating

Heat

Resistance

Supply Fan Output

(b)

Cool and

Staged

Heat

Modulating

Heat

1

Fan On

Minimum

Position

Setpoint

0%

Off Off Off Off 0%

2.2K

Ω 50%

Minimum

Ventilation

On Selectable Off Off Off Off 0%

2

Economizer

Test Open

On Open Off Off Off Off 0% 3.3K

Ω 50%

(c)

3

Cool

Stage 1

On

Minimum

Position

On

(d)

Off Off Off 0% 4.7KΩ 82%

4

(e)

Cool

Stage 2

On

Minimum

Position

On

(d)

On

(d)

Off Off 0% 6.8KΩ 100%

5

(e)

Cool

Stage 3

On

Minimum

Position

On

(d)

On

(d)

Off Off 0% 8.2KΩ 100%

6

(e)

Reheat On Minimum On On Off Off 0% 33KΩ 100%

(f)

—

7

(e) (g)

Heat

Stage 1

On Minimum Off Off On/50%

(h)

Off 50% 10KΩ 100% 50%

(h)

8

(e)

Heat

Stage 2

On Minimum Off Off

On/

100%

(h)

On 100% 15KΩ 100% 100%

(h)

(a) The exhaust fan will turn on anytime the economizer damper position is equal to or greater than the exhaust fan setpoint.

(b) The supply fan output is in reference to the user selected maximum unit fan speed.

(c) Regardless of the economizer mode configuration, the unit will run the supply fan at the minimum speed during the economizer step of the service test.

(d) The condenser fans will operate any time a compressor is ‘On’ prov

iding the outdoor air temperatures are within the operating values.

(e) Steps for optional accessories and non-appli

cable modes in unit will be skipped.

(f) Units with enhanced dehumidification only will no

t perform this step during service test.

(g) For ultra Low NOX gas furnace units, the vestibule temperature limit switch must also be in closed state in order for the gas valve an

d the premix blower

to be energized for Heat Stage 1.

(h) Supply fan output for modulating gas heat will be a percentage of the user selected maximum supply fan speed. Values shown represent SZVAV/MZVAV.

Loading...

Loading...