12 18-CD19D5-10

Installer’s Guide

VENT FITTING MATERIAL – PLASTIC

Gas and liquid tight single wall vent fittings, designed for

resistance to corrosive flue condensate, MUST be used

throughout.

Listed in Table 7 are fittings that meet these requirements. The

materials listed are various grades of PVC and ABS plastic.

PIPE JOINTS: All joints must be fastened and sealed to prevent

escape of combustion products into the building.

NOTE:

It is recommended that the first joints from the furnace be

connected and sealed with high temperature RTV. This will

enable the pipes to be removed later without cutting.

Be sure to properly support these joints.

BONDING OF PVC

Commercially available solvent cement for PVC must be used to

join PVC pipe fittings. Follow instructions on container carefully.

Pipe and Fittings – ASTM D1785, D2466, D2661, & D2665

PVC Primer and Solvent Cement – ASTM D2564

Procedure for Cementing Joints – Ref ASTM D2855

1. Cut pipe square, remove ragged edges and burrs. Chamfer

end of pipe, then clean fitting socket and pipe joint area of

all dirt, grease, moisture or chips.

2. After checking pipe and socket for proper fit, wipe socket

and pipe with cleaner-primer. Apply a liberal coat of primer

to inside surface of socket and outside of pipe. DO NOT

ALLOW PRIMER TO DRY BEFORE APPLYING CEMENT.

3. Apply a thin coat of cement evenly in the socket. Quickly

apply a heavy coat of cement to the pipe end and insert pipe

into fitting with a slight twisting movement until it bottoms

out.

4. Hold the pipe in the fitting for 30 seconds to prevent

tapered socket from pushing the pipe out of the fitting.

5. Wipe all excess cement from the joint with a rag. Allow 15

minutes before handling. Cure time varies according to fit,

temperature and humidity.

NOTE:

Follow venting instructions carefully when using PVC cement.

IMPORTANT:

All joints must be water tight. Flue condensate is somewhat acidic,

and leaks can cause equipment damage.

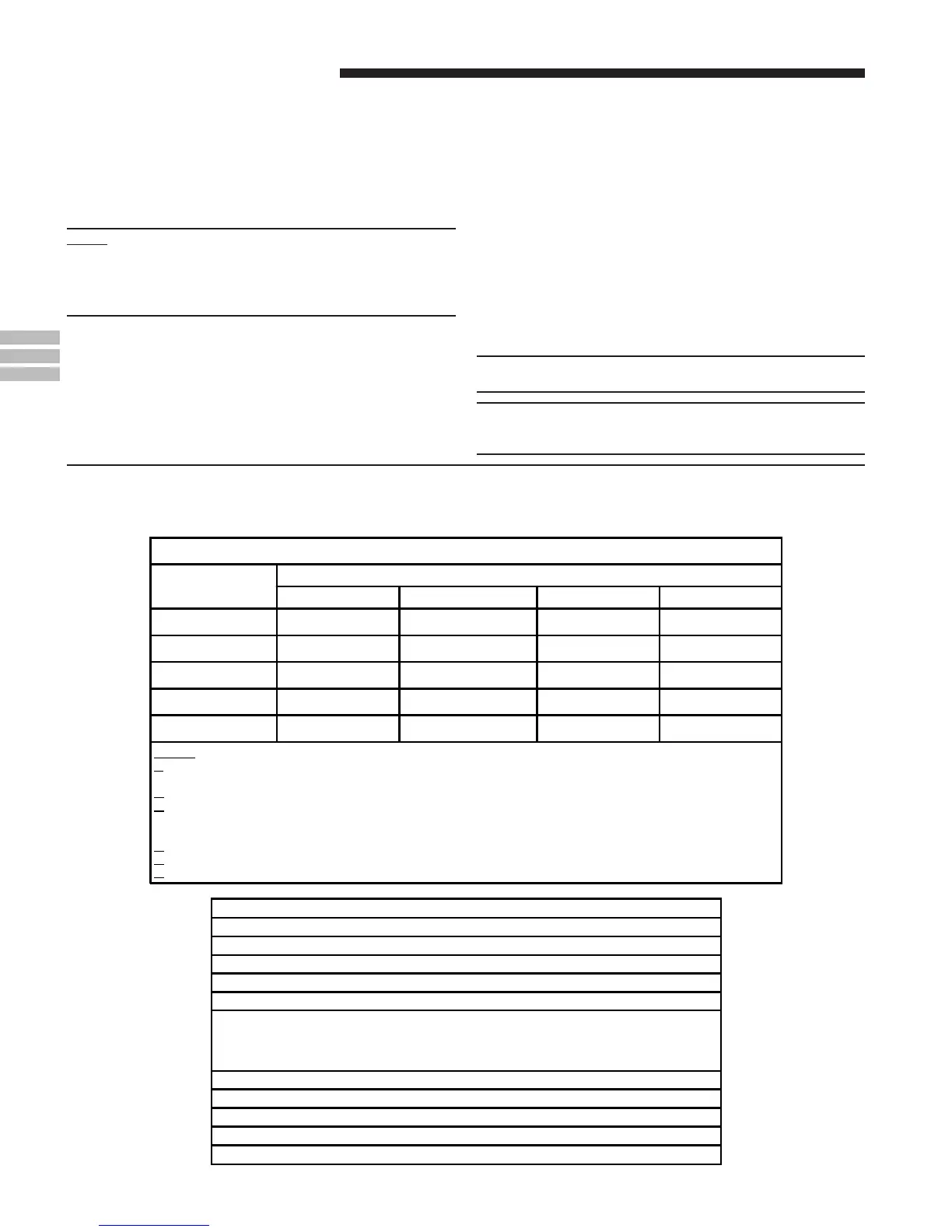

MAXIMUM VENT LENGTHS

UPFLOW / HORIZONTAL and DOWNFLOW / HORIZONTAL VENTING TABLE

TABLE 7

MAXIMUM VENT LENGTH:

MODEL

MAXIMUM TOTAL EQUIVALENT FEET

2" PIPE & FITTINGS 2-1/2" PIPE & FITTINGS 3" PIPE & FITTINGS 4" PIPE & FITTINGS

*UC/*DC040C

50 80 80 130

*UC/*DC060C

50 80 80 130

*UC/*DC080C

40 80 80 130

*UC/*DC100C 30 80 80 130

*UC/*DC120C

NOT ALLOWED 25 70 130

NOTES:

* - First letter may be "A" or "T"

1.

DO NOT MIX PIPE DIAMETERS IN THE SAME LENGTH OF PIPE OUTSIDE THE FURNACE CABINET

(Except adapters at top of furnace).

2.

MAXIMUM PIPE LENGTHS MUST NOT BE EXCEEDED!

3.

One 90° elbow is equivalent to 12' of 4" pipe. One SHORT radius 90° elbow is equivalent to 10' of 3" pipe and one

LONG radius elbow is equivalent to 6' of 3" pipe. One SHORT/LONG radius 90° elbow is equivalent to 7½' of

2½" pipe, & 5' of 2" pipe. Two 45° elbows equal one 90° elbow.

4.

The termination tee or bend must be included in the total number of elbows.

5.

Pipe adapters are field supplied. Downflow models and *UC120 include 2" X 3" adapter.

6.

4" pipe may be reduced to 3" for termination with BAYVENT100 or BAYVENT200 without length restriction

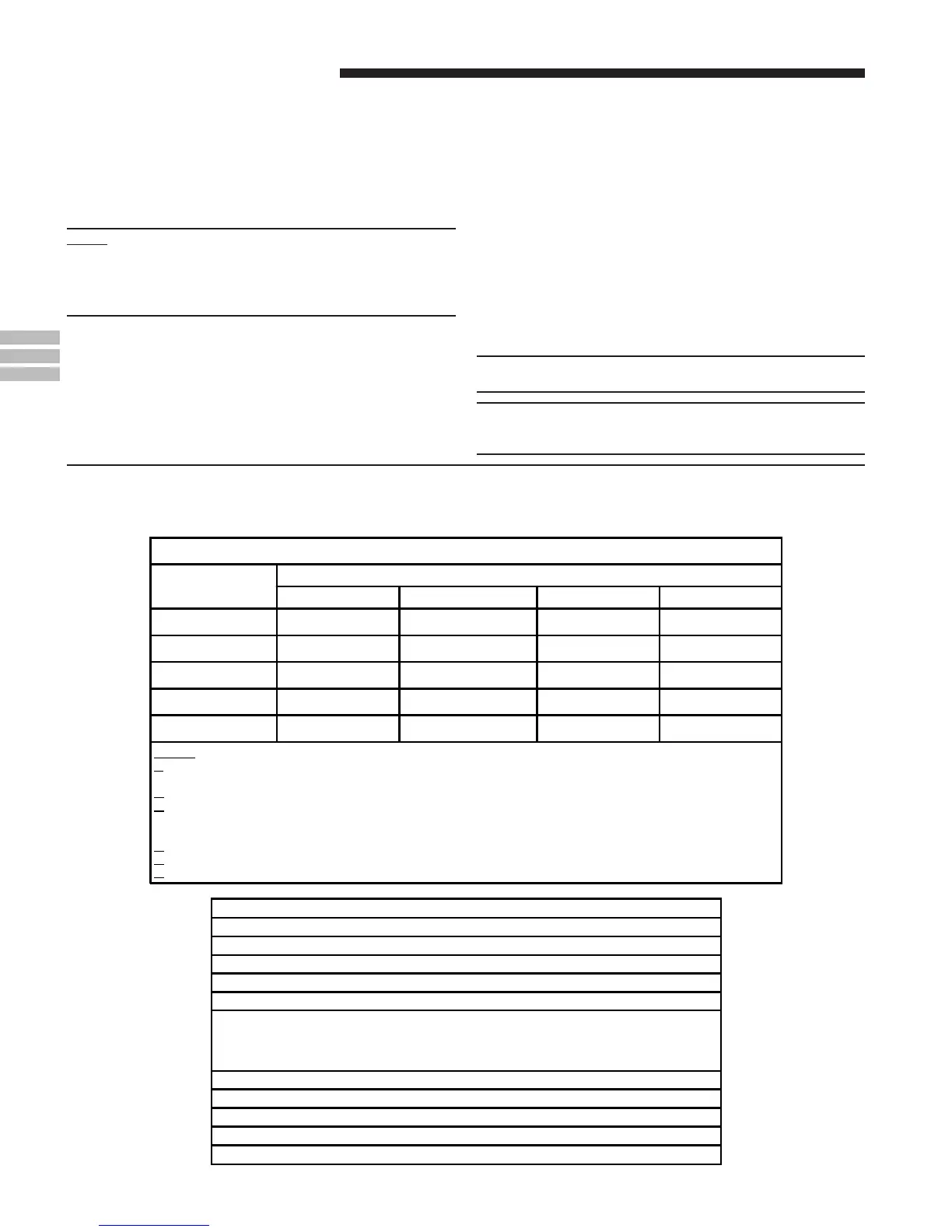

INTEGRATED FURNACE CONTROL ERROR FLASH CODES

Flashing Slow --- Normal - No call for Heat

Flashing Fast --- Normal - Call for Heat

Continuous ON --- Replace IFC

Continuous OFF --- Check Power

2 Flashes --- System Lockout (Retries or Recycles exceeded)

3 Flashes ---

Draft Pressure Error - Possible problems:

a) Venting problem

b) Pressure switch problem

c) Inducer problem

4 Flashes --- Open Temperature Limit Circuit

5 Flashes --- Flame sensed when no flame should be present

6 Flashes --- 115 volt AC power reversed, poor grounding or system voltage too low

7 Flashes --- Gas valve circuit error

8 Flashes --- Low flame sense signal

Loading...

Loading...