Semi-Auto Strapping Machine TP-201/202/203/202L

Q&A

Confidential TO: FROMM HOLDING AG

Page 5 of 7 8/19/2008

XII. Insufficient tension

(a) Turn TB-251 Tube B clockwise to required tension.

(b) Clean the contacting surface of TB-176 Friction Disc & TB-170 Pulley from oil and

dirt.

(c) Replace TB-176 Friction Disc.

(d) Replace TB-170 Pulley and TB-175 Plate.

(e) Package width is too small{minimum package size is 80mm width}

(f) The Bearing, 635ZZ (BR635ZZ) is broken.

XIII. The activating time is 2-3 seconds after the p.p. strap has been inserted

into the strap inlet (activation too slow)

(a) Voltage is too low.

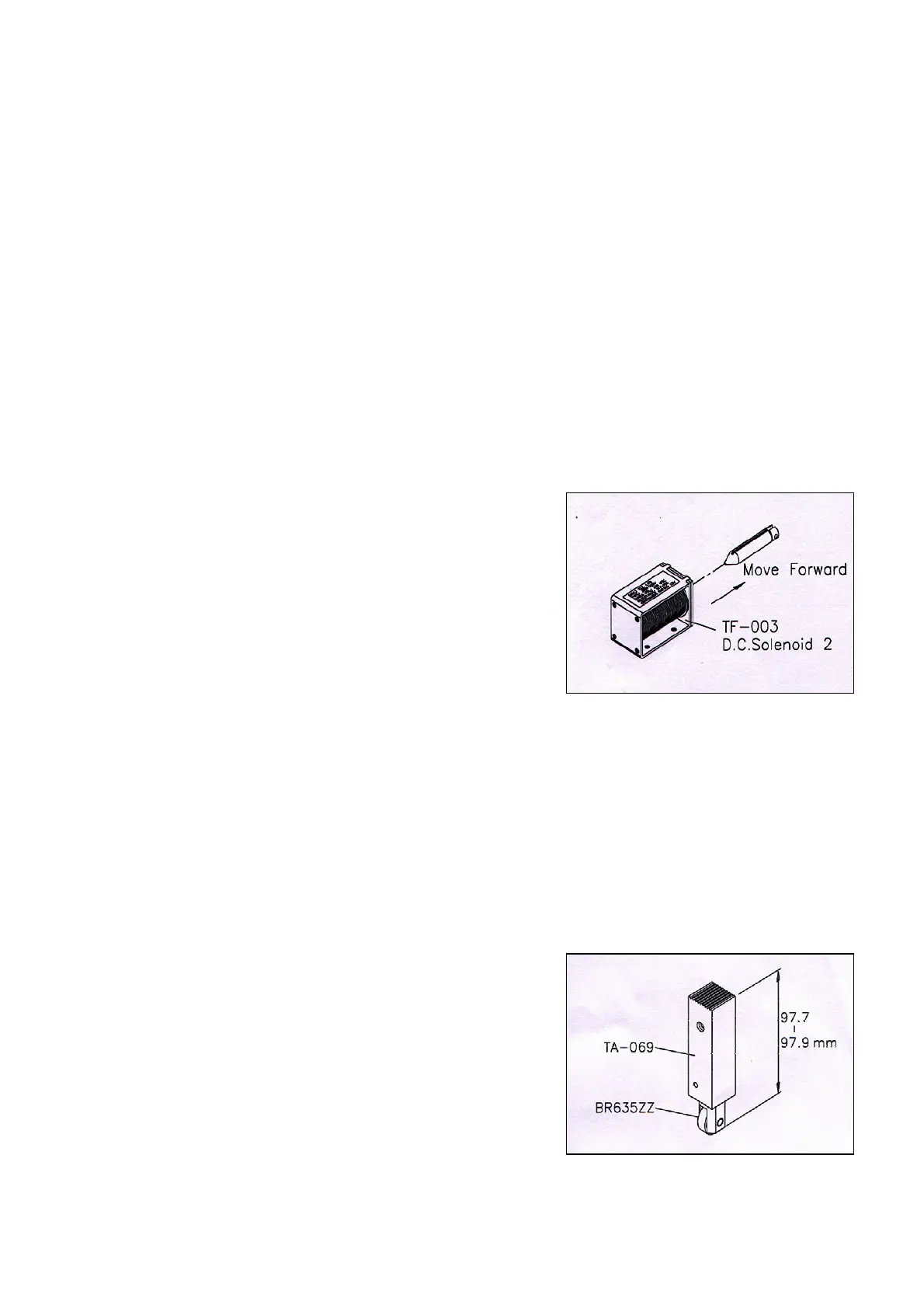

(b) Slightly release TA-114 Spring of TF-003 D.C.

Solenoid (SOL 2).

(c) Slightly move TF-003 D.C. Solenoid (SOL. 2)

forward. (refer to the drawing on the right)

(d) Replace TF-003 D.C. Solenoid (SOL. 2).

(refer to the drawing on the right).

XIV. P. P. Strap will not seal

(a) The temperature setting of TB-113 Heater is too high or too low. Set the TF-023

Heater Transformer to value 4 or 5.

(b) Clean the surface of heater plate from dust.

(c) Replace the TB-113 Heater Ass'y.

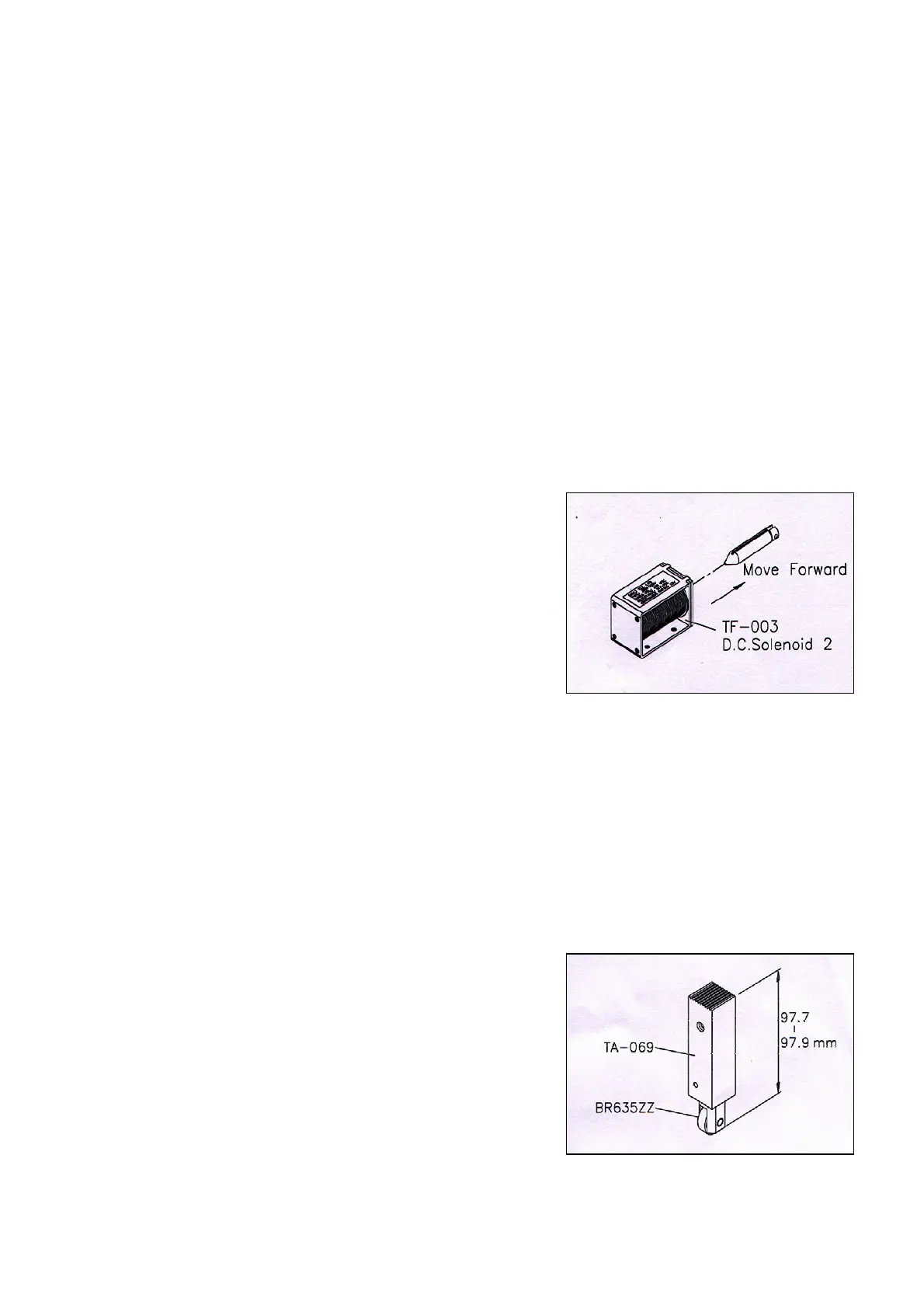

(d) Check if the BR635ZZ Bearing of TA-069 Press Bar is broken.

(e) Check if tension is too high. If so, turn the TB-251 Tube B counterclockwise (reduce

tension).

(f) Replace the TB-114 Return Spring of TB-102

Heater Arm.

(g) The total height of TA-069 Press Bar including

BR635ZZ Bearing is too short. It should be set

to 97.7mm-97.9mm. (refer to the drawing on the

right)

(h) Check if the TA-078 Spring of TA-069 Press Bar

is overstretched.

Loading...

Loading...