TRI TOOL INC.

92-0579 Rev. 190612

14

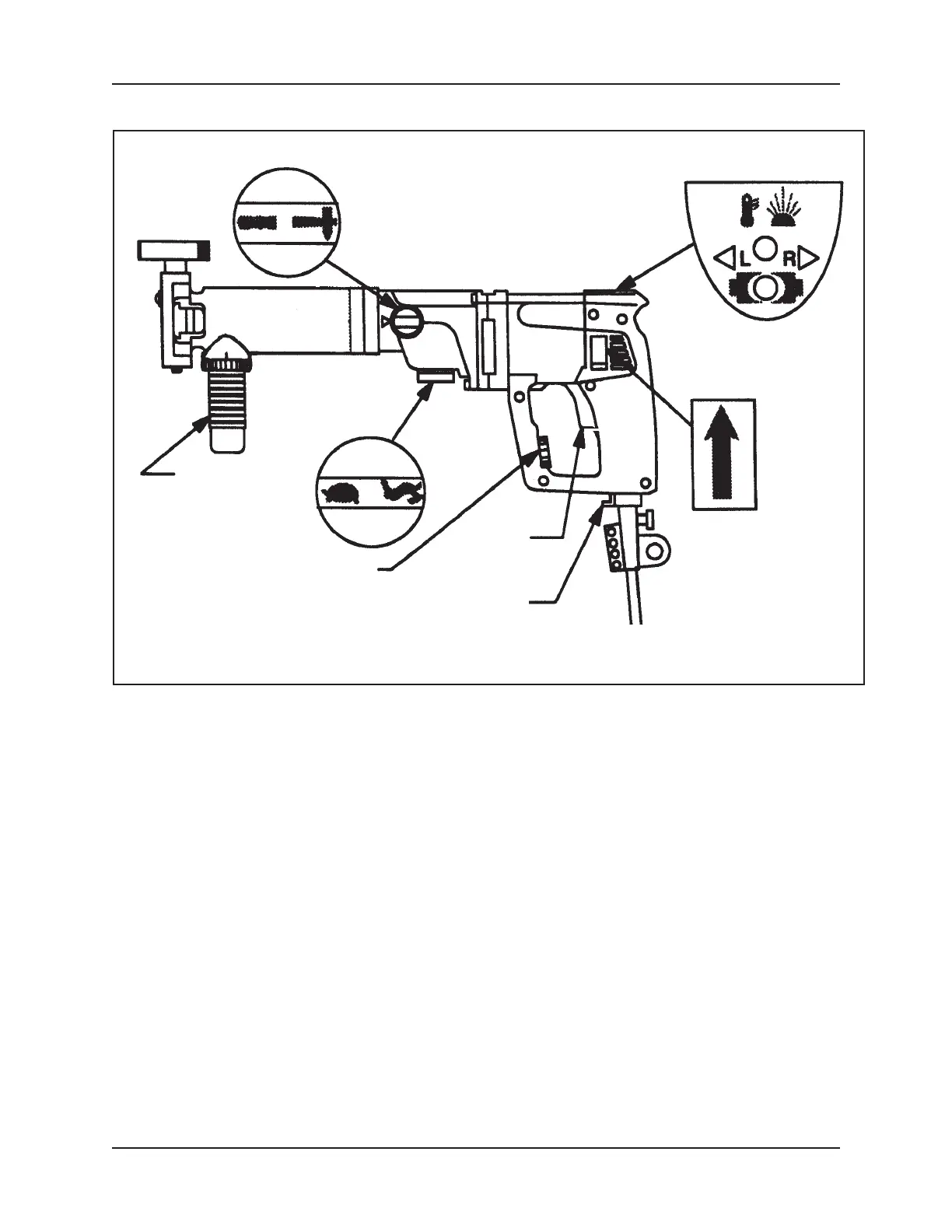

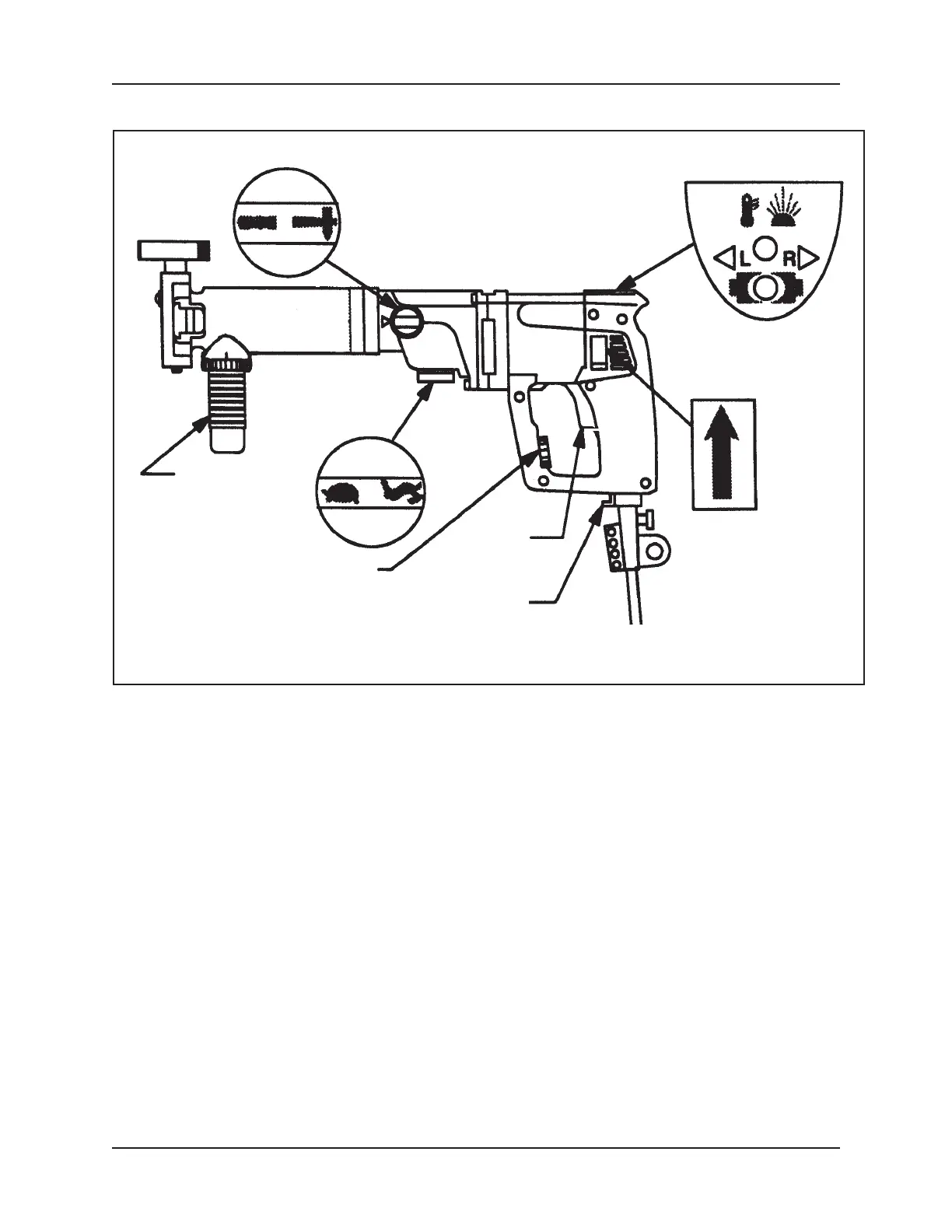

16. For Metabo Motor only

• The Two Speed Gearbox Knob should be in the position in Fig 7. If the

Knob does not snap into the desired position, turn the chuck by hand

slightly until the knob snaps into place.

• The Impact Knob should be in the position shown.

• The Rotation Control Switch should be in the position shown. The ‘R’ LED

on the LED Display should be lit.

17. Use the Feed Handle to feed the Shaft with the tool bit into the work

18. In order to obtain a minimum burr tube end, avoid heat build up. When

eitherthetubeorthetoolbitgethot,thetubematerialstartstoowor

push away from the tool bit edge in the form of a burr, instead of being

cut cleanly with a minimum burr. Avoid the conditions which generate

excessive heat by keeping the RPMs low. Excessive cutting speed will

generate unwanted heat.

19. Keep the chip curling loose by avoiding an excessive depth of cut. A dull

tool bit will not do the job right, so be sure that there is a sharp tool bit

mounted in the Machine.

Figure: 7. Metabo Motor Controls

Impact Selection

Knob

Two Speed

Gearbox Knob

Feed Handle

Speed Control

LED Display

Rotation

Control

Switch

Trigger

Trigger

Lock

Loading...

Loading...