ARBOR FLOAT

Page 14

A float-free arbor, and firm mountings between the motor and baseplate, are most important.

Check for arbor float as described above. To check the mountings, hold the baseplate down on a

flat surface, and see how much you can move the motor up and down. Test at different height and

angle settings.

Most circular saws have a height adjustment pivot at the front, with the locking lever/knob behind

the motor. They are the preferred type. Vertical lift (plunge-type) saws should only be fitted if they

remain rigid and accurate throughout their height and angle adjustment range.

A 235mm (9 1/4”) saw is best for heavy work, requiring a large depth of cut or extra power. 208mm

(8 1/4”) or 185mm (7 1/4”) saws are quite adequate. If considering upgrading your saw, the Triton

235mm Precision Power Saw is highly recommended.

SELECTING A SAW BLADE

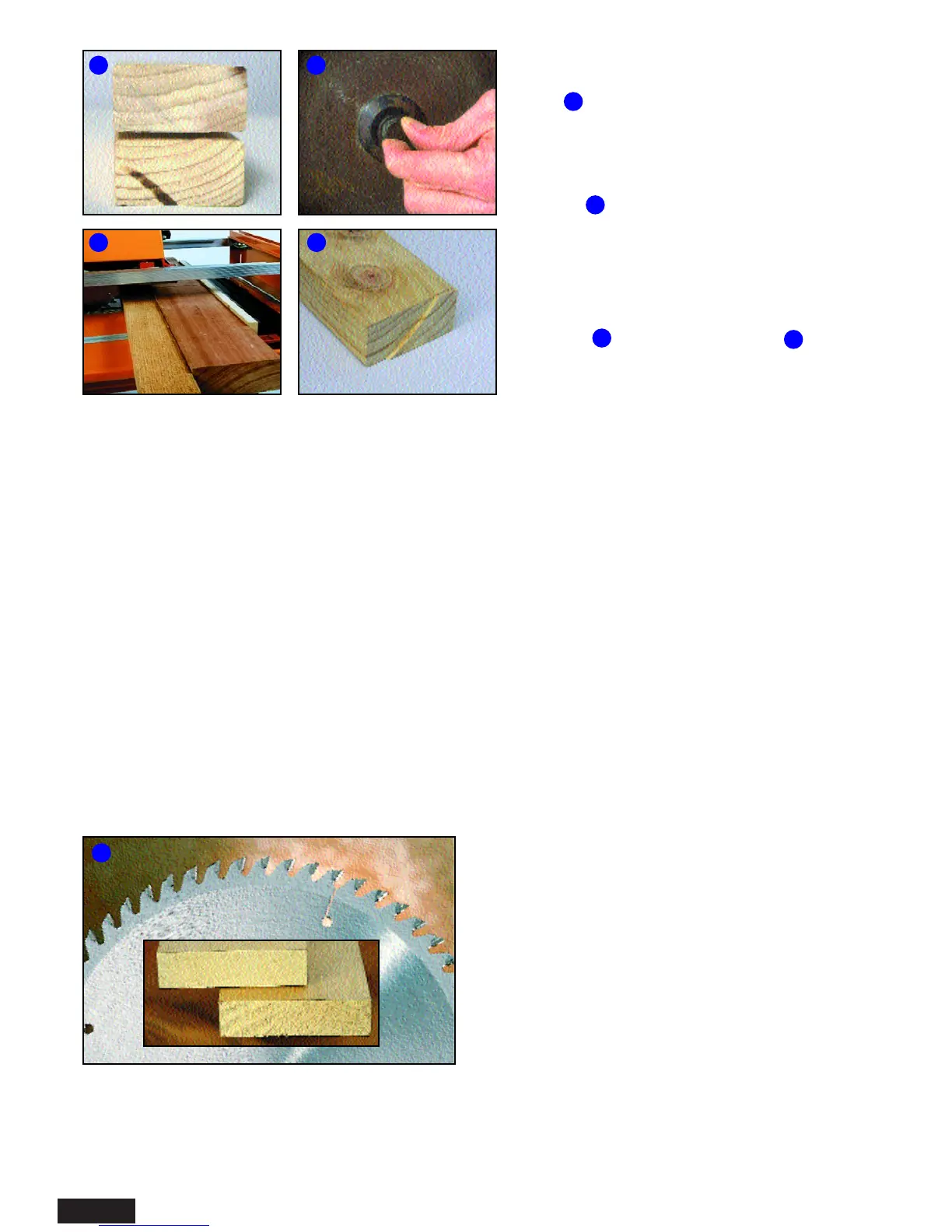

This is one of the key factors for square, smooth cuts with a minimum of splintering. We strongly

recommend tungsten carbide tipped (TCT) blades.

Triton Premium TCT Saw Blades have been

expressly designed for the Workcentre and have a

unique tooth design. They cut very cleanly, reduce

arbor float-related problems, and minimise

splintering, especially in veneered boards.

The number of teeth depends on the work you’ll

mainly be doing: for crosscutting, the more teeth

the better. A 184mm saw should have 30 - 40 teeth

and a 235mm saw should have 40 - 60 teeth.

Ripping generally requires fewer teeth, (20 - 32 on a 235mm blade), with larger gullets behind the

teeth to help clear the longer curls of saw dust created when ripping natural timbers.

If you can only afford one blade, we suggest more teeth rather than fewer. Just slow down the feed

rate when ripping natural timbers.

Triton TCT Saw Blade Cut

Standard Saw Blade Cut

If your cuts have ridges, burn marks or high

spots , the saw is mounted skew on the

slide chassis, or it has arbor float, or the

blade is blunt / buckled. Check for arbor float

by unplugging, gripping the blade or blade

nut, and pulling in and out in the direction of

the shaft. Any movement is undesirable.

For perfectly square cuts, you may have to

repair or upgrade your saw.

You might reduce the problem by placing a

parallel-sided packer between your work and

the fence. Also try shaving cuts, where

the second (shaving) cut removes say 1 mm

of material, putting less load on the arbor.

SELECTING A CIRCULAR SAW

1 2

3 4

5

1

2

3

4

Packer

Loading...

Loading...