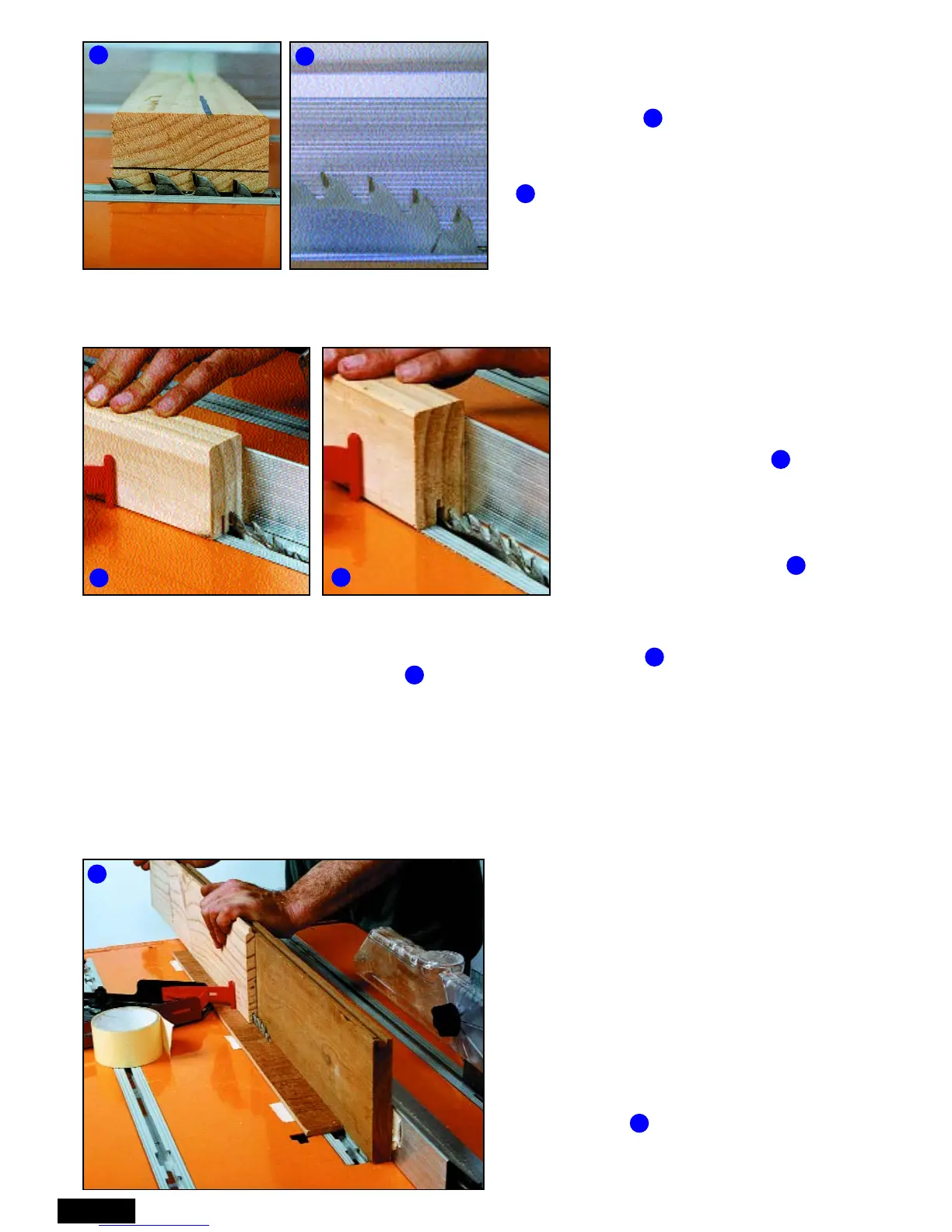

Study the previous section on Edge

Rebating. Make two identical rebates

from opposite faces of the workpiece,

leaving you with a central tongue.

Complete the tongue with the wood

lying down flat as shown in ,Page 17.

To make a matching groove, move the

fence outwards (by one blade width

from the tongue setting) and make two

cuts from the opposite faces.

Raise the blade 0.5mm before cutting the groove, to allow for glue and to ensure a tight joint.

Page 18

Always make the first two cuts into the narrower edge of the workpiece , and the two final cuts

with the workpiece lying down flat (as in on Page 17). Otherwise, your workpiece could be left

balancing unsafely on the narrow tongue after the final cuts.

To set the blade to a desired depth of cut,

mark it on a piece of wood. Lay the wood

beside the blade, leaving both hands free for

adjusting the saw. Or use the 2mm &

10mm calibration marks on the face of the rip

fence for setting blade height.

In the blade is set to 30mm, the third deep

groove up from the table. (These calibrations

are approximate only and should be verified by

a test cut on some scrap.)

Test fence and blade height settings on short off-cuts of the wood you’ll be using. If joining long

pieces (which might not be dead straight), make the test pieces a slightly loose fit. Otherwise you could

have problems cramping the job up tightly.

You cannot use the overhead guard so be very

careful with your hand positions.

50

40

10

20

30

60

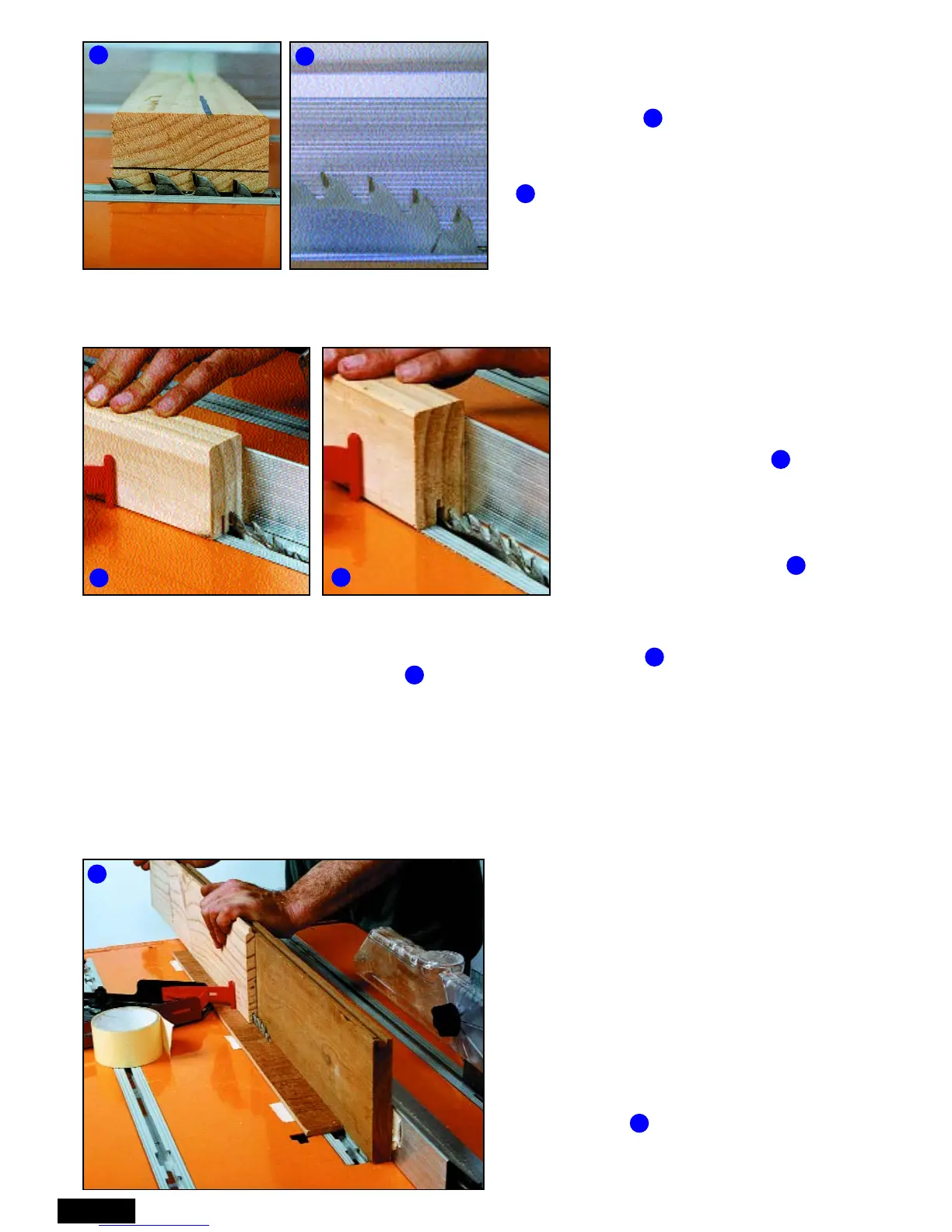

If rebating or tongue & grooving very thin

boards, the workpiece could be unstable

standing on it’s narrow edge.

Attach a suitable height sub-fence to the rip

fence for extra vertical support. (Use strong

double-sided tape - 50mm carpetlaying tape is

ideal - or countersunk bolts and nuts by

removing the fence end caps.) If necessary

use a piece of ply or hardboard with a thin slot

in it for the blade. Securely tape it to the table

as a mask, and have the blade protruding as

little as possible.

1

2

3

4

5

1

2

4

4

3

5

TONGUE & GROOVING

EDGE WORK ON THIN MATERIAL

4

Loading...

Loading...