Functions

VARIABLE SPEED CONTROL

Router speed settings are not critical

- generally the highest speed which

does not result in burn marks on the

workpiece should be used. Where

stated, always follow the cutter

manufacturer's maximum speed

limitations.

Operating at reduced speed

increases the risk of damage to

the router as a result of overload. Use very slow feed rates and/or

multiple shallow cuts.

The Speed Controller (1) is marked 1 to 5, corresponding

approximately with the speeds and cutter diameters below.

Turn the dial to select the speed.

DUST EXTRACTION

Dust Port

The Triton Router is equipped with

a Dust Extraction Port (16) for chip

extraction above the cut. It accepts

38mm (1-½") O.D. hose, supplied

with the Triton Dust Collector

(DCA300).

The hose screws into position via a left hand thread

(anticlockwise).

OPTIONAL CHIP COLLECTOR

ACCESSORY

An optional Dust Chute for effective

chip extraction alongside the cut

zone is available through your local

Triton retailer. It can be connected to

any 38mm (1-½") O.D. hose.

DEPTH STOP & TURRET

• The depth stop and turret enable accurate pre-setting of two

different cut depths in free plunge mode

Setting RPM Cutter Diameter

5 20,000 Up to 25mm (1")

4 18,000 25 - 50mm (1" - 2")

3 14,500 50 - 65mm (2" – 2-

1

⁄2")

2 11,000 Over 65mm (2-

1

⁄2")

1 8,000 Use only if burning

Zeroing the router

1. Fit the router bit you require and

place the router, right side up, on

the work bench

2. Rotate the Turret (9) until the

fixed post is beneath the depth

stop

3. Loosen the Depth Stop Lock

Knob (6) so that the depth

stop is fully released

4. Release the Plunge Lock

Lever (10), then plunge the

router until the tip of the

bit is in contact with the

surface of the work bench

5. Now tighten the Depth Stop

Lock Knob (6) so that the

depth stop is locked in its current

position

Pre-setting the cut depths

1. The top of the fixed post now

provides an accurate datum,

and the depth of cut can be set

by reference to the graduations

printed on the side of the fixed

post

2. To set a cut depth, rotate the

thumbwheel on one of the

Turret Stops (9) until the top of

the thumbwheel aligns with the

depth of cut required (as shown

on the fixed post) For example,

for a cutting depth of 3mm,

rotate the thumbwheel until the

top is aligned with the 3mm

mark on the fixed post. For a

cutting depth of

1

⁄8", rotate the

thumbwheel until the top is

aligned with the

1

⁄8" mark on the

fixed post

3. To pre-set a second depth, repeat the procedure with the

second thumbwheel

Plunging to pre-set depth

• Rotate the turret until the thumbwheel at the required depth is

positioned beneath the depth stop

• Now, when you plunge the router, the depth stop will hit the

thumbwheel and retain the router at the precise depth required

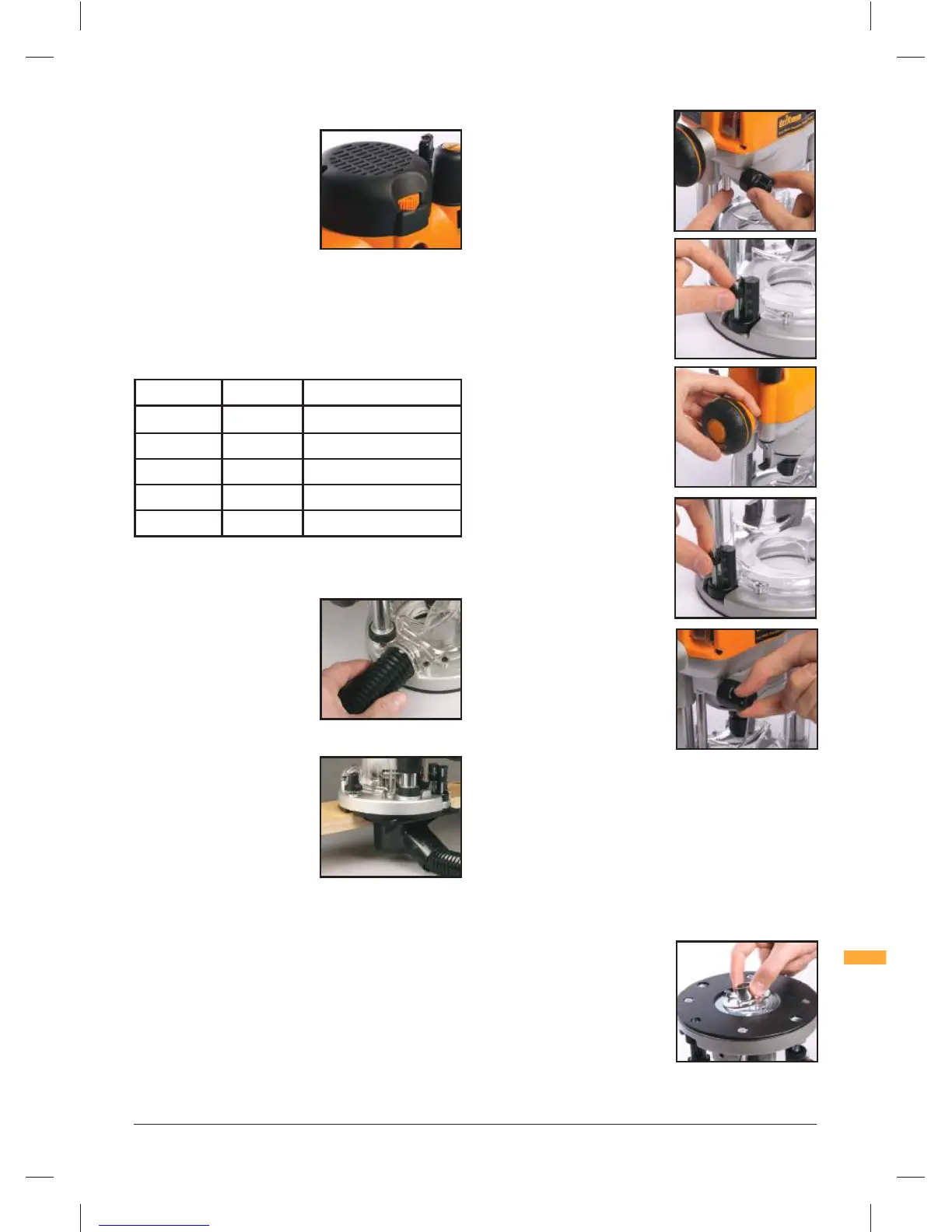

OPTIONAL TEMPLATE GUIDE BUSHES

Different template guide bushes

are available for template routing.

Accessory kits are available through

your local Triton retailer.

330165_Z1MANPRO1(with Japanese).indd 7 21/07/2014 09:49

Loading...

Loading...