7

Selecting a table insert

Failure to use the correct table insert with its matching sanding sleeve could

result in pinched fingers or the workpiece being pulled down between the

table insert and the sanding sleeve.

The sanding sleeve should fit snugly into the central cutout of the table insert

(images B and C).

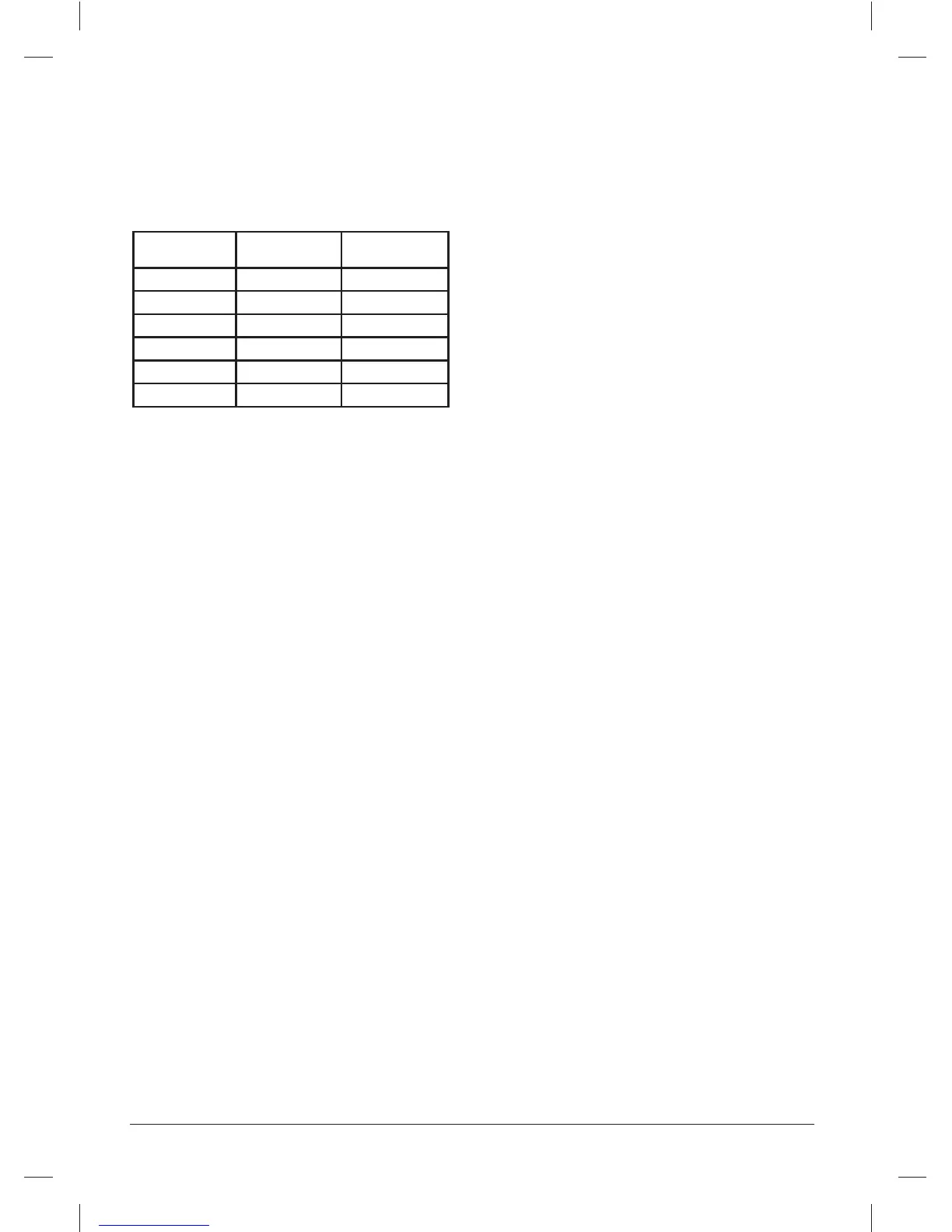

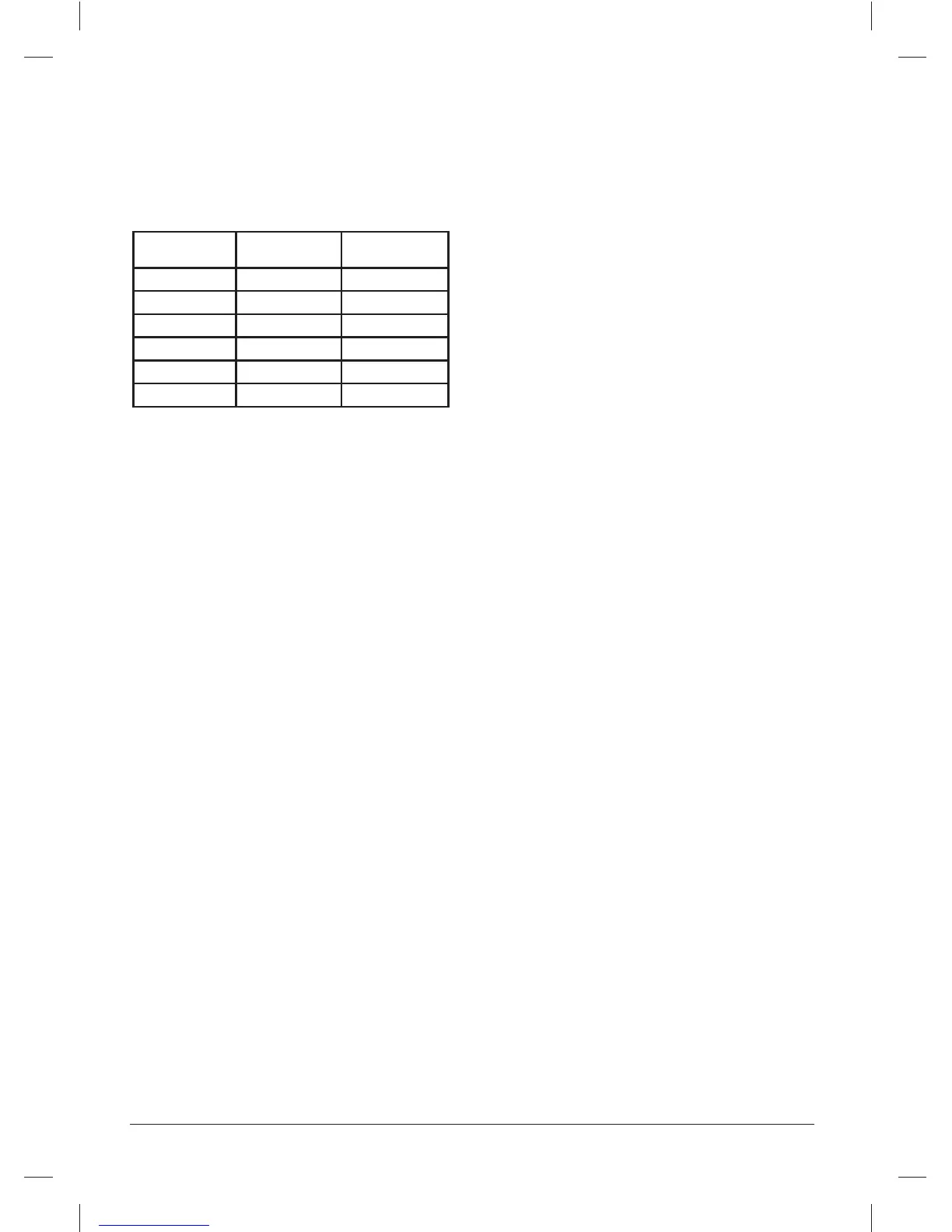

Use the following chart to help determine the correct table insert and upper

spindle washer to use with each sanding sleeve.

Sanding Sleeve Dia Table Insert Size Upper Spindle

Washer Size

13mm 13mm Small

19mm 19mm Medium

26mm 26mm Medium

38mm 38mm Large

51mm 51mm Large

76mm 76mm Large

Selecting the right grade of sanding disc

• Sanding discs are available in a variety of different grades: coarse (80 grit),

medium (150 grit) and fine (240 grit)

• Use a coarse grit to sand down rough finishes, medium grit to smooth the

work, and fine grit to finish off

• Always use good quality sanding sleeve to maximise the quality of the finished

task

• It is advisable to do a trial run on a scrap piece of material to determine the

optimum grades of sanding sleeve for a particular job. If there are still marks

on your work after sanding, try either going back to a coarser grade and

sanding the marks out before recommencing with the original choice of grit,

or try using a new piece of sanding sleeve to eliminate the unwanted marks

before going on to a finer grit and finishing the job

Fitting a sanding sleeve

Note: All of the sanding sleeves, except the smallest 13mm (1⁄2") sanding

sleeve fit over a matching Rubber Drum (6).

Note: Ensure there is no contact between the Sanding Sleeve and the Table

Insert before turning the machine on.

1. Fit the lower spindle washer (12) over the spindle (4) with the grooves facing

upwards (image D)

2. Select the correct Sanding Sleeve (7) for the intended job. Select the

corresponding Rubber Drum (6), (except when using the 13mm sanding

sleeve). Do not use a sanding drum with the 13mm (1⁄2") sanding sleeve.

3. Select the appropriate Table Insert (5) in accordance with table above (see

‘SELECTING A TABLE INSERT’)

4. Fit the Table Insert (5) over the Spindle (4) and onto the lower spindle washer

(see image V). Ensure the table insert is flush with the table

5. Fit the Rubber Drum (6) over the spindle (image E and F)

6. Slide the Sanding Sleeve (7) over the Rubber Drum (6)

7. Fit the upper Spindle Washer (13) over the Spindle (4)

• Use the large washer with the 75mm (3"), 51mm (2"), and 38mm (1 1⁄2")

rubber drums.

• Use the medium washer with the 26mm (1") and 19mm (3⁄4") rubber drums

• Use the small washer with the 13mm (1⁄2") sanding sleeve

8. Fit the Spindle Lock Nut (15) on the Spindle (4) (image G and H). Tighten the

nut just enough to expand the Rubber Drum (6) against the Sanding Sleeve (7).

Do not over-tighten

When the sanding sleeve is completely worn it is possible to turn it upside

down and maximise its service life by using the remaining grit.

Do not use a sanding sleeve that is too worn. This can lead to excessive heat

build-up and damage the rubber drum. Damaged rubber drums due to worn

sanding sleeves will not be covered under warranty.

Operation

WARNING: ALWAYS wear eye protection, adequate respiratory and hearing

protection, as well as suitable gloves, when working with this tool.

Switching on and off

• The On/Off Switch (1) is located on the front of the spindle sander (see image I)

• To turn the spindle sander ON, pull the switch plate up

• To turn the spindle sander OFF, push the switch plate down

• The power switch can be locked to prevent unauthorised use:

1. To lock the switch, switch off the tool and disconnect it from mains power

2. Pull the switch lock key out. If the key is removed with the switch in the 'on'

position, the switch can be turned off but cannot be turned on

3. Refit the key by sliding it into the slot on the switch until it snaps into position

Sanding

WARNING: Do not sand metal with this sander. Sanding metal will cause

sparks that may ignite wood and dust particles on the sander or in the

workshop

WARNING: Feed the workpiece gradually, AGAINST the direction of rotation,

onto the sanding sleeve. Failure to do this could force the workpiece away

from the sanding sleeve with risk of injury. Do not force the workpiece or apply

excessive force.

NOTE: The spindle rotates in an anti-clockwise direction

1. Check the machine is mounted securely on the workbench and the Spindle

Lock Nut (15) is fastened correctly with appropriate sanding sleeve and table

insert, in accordance with guidance in ‘Assembly’

2. Ensure you are wearing all appropriate safety equipment, including face mask

and safety glasses, then switch on the dust extraction system (if available)

3. Turn the sander ON and allow the motor to reach full speed

4. Feed the workpiece gradually, AGAINST the direction of rotation, onto the

sanding sleeve

• Do not force the workpiece or apply excessive pressure

• Guide the workpiece against the direction of rotation only, or the rotation forces

of the spinning sanding sleeve will tend to throw or bounce the workpiece

away from the sanding sleeve

5. When finished, turn off the machine and disconnect from mains power

Accessories

• A range of accessories and consumables, including TSS80G, TSS150G,

TSS240G Sanding Sleeves are available from your Triton stockist. Spare parts

can be obtained from toolsparesonline.com

Maintenance

WARNING: ALWAYS disconnect from the power supply before carrying out any

inspection, maintenance or cleaning.

General inspection

• Regularly check that all the fixing screws are tight

• Inspect the supply cord of the tool, prior to each use, for damage or wear.

Repairs should be carried out by an authorised Triton service centre. This

advice also applies to extension cords used with this tool

Cleaning

• Keep your tool clean at all times. Dirt and dust will cause internal parts to wear

quickly, and shorten the machine’s service life. Clean the body of your machine

with a soft brush, or dry cloth. If available, use clean, dry, compressed air to

blow through the ventilation holes

• Clean the tool casing with a soft damp cloth using a mild detergent. Do not use

alcohol, petrol or strong cleaning agents

• Never use caustic agents to clean plastic parts

Lubrication

• Slightly lubricate all moving parts at regular intervals with a suitable spray

lubricant

643723_Z1MANPRO1_AUS.indd 7 24/02/2015 16:42

Loading...

Loading...