2.

Chipper Chute (Inlet)

The Chipper Chute on the side of

your

equipment

lets you process into "chips" larger materials that the

Shredder can't handle. The Chipper Chute

is

shown

in

aclose-up in Photo 3-3. Branches fed intothe chute are

turned into "chips" by a revolving blade mounted on a

flywheel.

We

recommend that branches and vines from

%,'-to-2" in diameter be fed intothe ChipperChute. Cut

your

materials into manageable lengths before pro-

cessing them.

A DANGER

Internal

Chipper/Shredder

Chamber

"Cutaway View"

4.

Discharge Area

The Discharge Area is located near the bottom of

yourequipment. This

is

where all chipped and shredded

materials exit once they've been processed.

See

Photo

3-5

for

a close-up view of the Discharge Area.

The holes

in

the Discharge Screen

not

only

provide

an

exit

for

processed materials, but hole size deter-

mines

how

finely materials are shredded. Shreddings

can't

be

discharged until they've been reduced to less

than the hole size

in

the screen. The Discharge Screen

supplied with

your

equipment is a general-purpose

screen designed to handle many kinds of materials

efficiently - it has

%" diameter holes which let all but

wet and green materials exit quickly. Also supplied with

your

machine is a Wet Material Baffle Attachment that

thoroughlyprocesses wet, heavy material with minimal

clogging.

It

must be used in place

of

the standard

screen when processing wet leaves, half-rotted com-

post, gone-by vegetables, and similar wet materials.

Access Via Service Door

__

Regular

%"

Discharge Screen

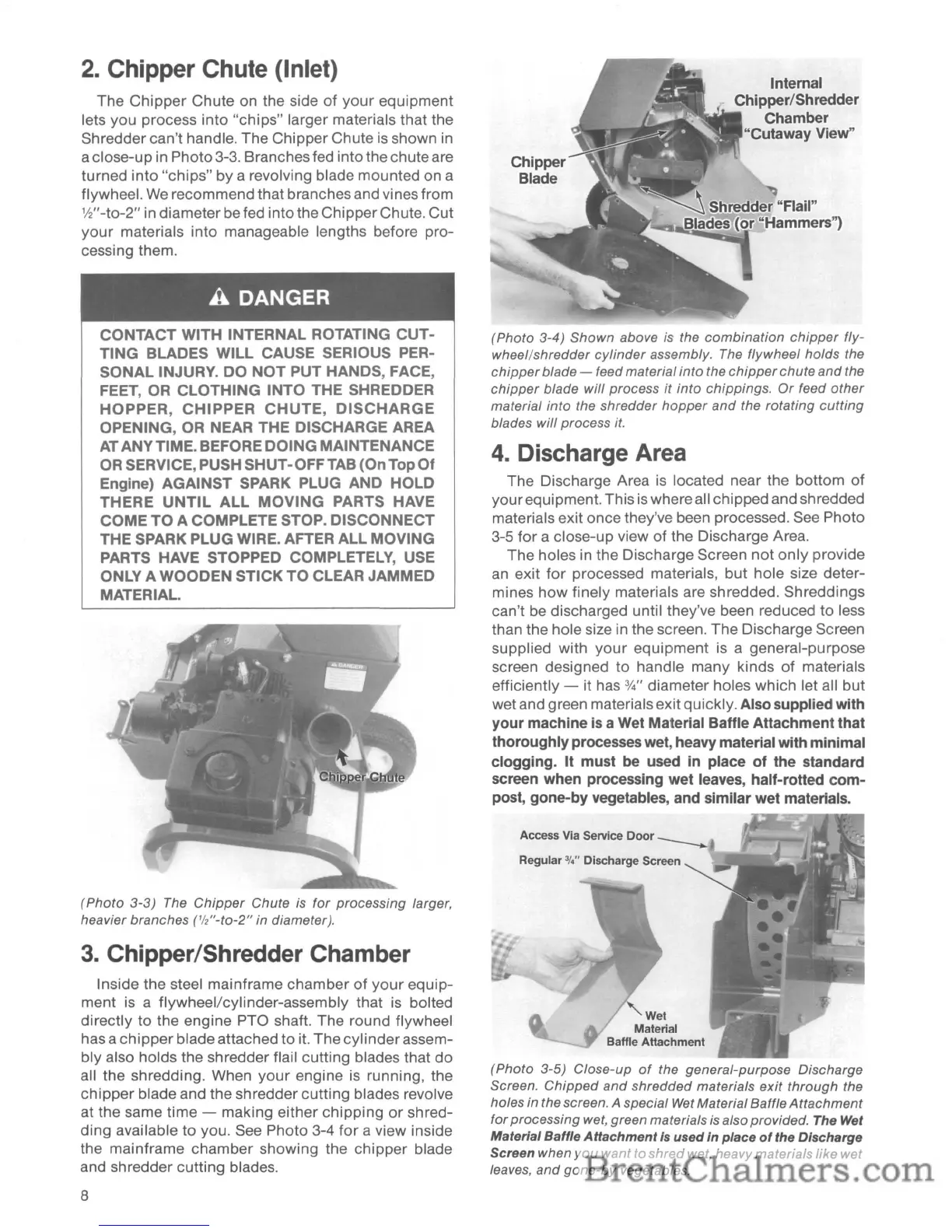

(Photo 3-4)

Shown

above is the

combination

chipper

fly-

wheel/shredder

cylinder

assembly. The flywheel holds the

chipper

blade - feed material

into

the

chipper

chute

and

the

chipper

blade will process

it

into

chippings.

Or

feed

other

material

into

the shredder

hopper

and

the rotating

cutting

blades will process

it.

(Photo 3-5) Close-up

of

the general-purpose Discharge

Screen.

Chipped

and

shredded

materials

exit

through

the

holes in the screen. A special

Wet

Material Baffle

Attachment

for

processing wet, green materials is also provided. The

Wet

Material Baffle

Attachment

is used

in

place

of

the Discharge

Screen when

you

want to

shred

wet, heavy materials like wet

leaves,

and

gone-by

vegetables.

3.

Chipper/Shredder Chamber

CONTACT WITH INTERNAL ROTATING

CUT-

TNG

BLADES WILL CAUSE SERIOUS PER-

SONAL INJURY.

DO

NOT

PUT HANDS, FACE,

FEET, OR

CLOTHING

INTO THE SHREDDER

HOPPER,

CHIPPER

CHUTE,

DISCHARGE

OPENING, OR NEAR THE DISCHARGE AREA

AT ANYTIME.BEFORE DOING MAINTENANCE

OR SERVICE, PUSH SHUT-OFFTAB (On Top Of

Engine) AGAINST SPARK PLUG AND HOLD

THERE

UNTIL

ALL

MOVING

PARTS HAVE

COME

TO

A COMPLETE STOP. DISCONNECT

THE SPARK PLUG WIRE. AFTER

ALL

MOVING

PARTS HAVE STOPPED COMPLETELY, USE

ONLY A WOODEN STICK

TO

CLEAR JAMMED

MATERIAL.

Inside the steel mainframe chamber of

your

equip-

ment

is

a flywheel/cylinder-assembly that

is

bolted

directly to the engine PTO shaft. The round flywheel

has a chipper blade attached to it. The cylinder assem-

bly also holds the shredder flail cutting blades that do

all the shredding. When your engine is running, the

chipper blade and the shredder cutting blades revolve

at the same time - making either chipping

or

shred-

ding available to you. See Photo 3-4

for

a view inside

the mainframe chamber showing the chipper blade

and shredder cutting blades.

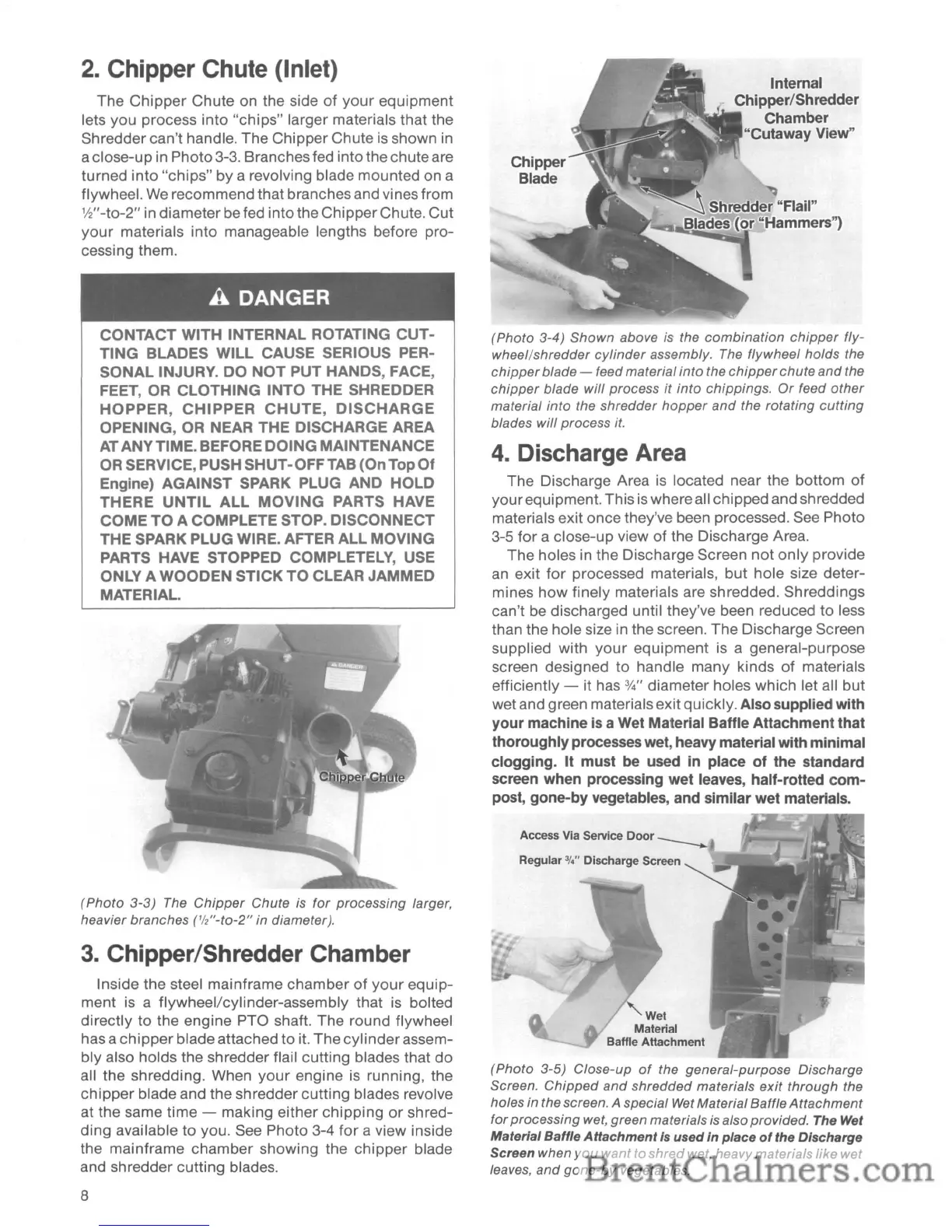

(Photo

3-3)

The

Chipper

Chute is for processing larger,

heavier branches ('/2"-to-2" in diameter).

8

Loading...

Loading...