22

ELECTRICAL CONNECTIONS

2

3

4

Hot Water Outlet Connection (Red Arrow)

Next, connect the outflowing Hot Water Supply main to the Outlet connection, indicated by the Red “Outlet

Water” tag. This is accomplished in a manner identical to connecting the inlet supply.

Turn on the water supply to the system. Open a hot water tap in the house to allow water to flow.

NOTE: Outflowing water will be cold at this point of installation. Water will not flow hot until electrical supply is

connected. Verify that the inlet and outlet connections are leak-free, both with water flowing and with the water

flow stopped. Maintain water pressure and check for leaks for a minimum of ten (10) minutes. If a slight leak is

noted at either of the stainless steel flexible line connection points, carefully tighten further with both wrenches

as noted above.

Pressure Relief Valve

Note that a temperature pressure and relief safety valve is not required according to national plumbing codes

as instantaneous water heaters are not considered pressure vessels. The trutankless comes equipped with a

mechanical thermal cut out and the copper manifold is not defined as a pressure vessel according to ASME. If

your water lines are plastic piping or tubing (PVC,PEX, Etc.), a pressure relief valve rated to equal or less than the

PSI rating of the tubing should be installed.

T&P valve may be required to meet installation codes in your area. If one is required, install the pressure relief

valve branched o the hot outlet side.

The trutankless TR/TC unit plumbing connections are now completed.

ABOVE INFORMATION IS MEANT ONLY AS A GUIDELINE AND SHOULD NOT BE RELIED UPON TO GUARANTEE SAFETY OF INSTALLATION OR CODE

COMPLIANCE. ELECTRICAL WIRING SHOULD ONLY BE PERFORMED BY A QUALIFIED AND PROPERLY LICENSED CONTRACTOR. PLEASE ENSURE YOUR

TRUTANKLESS MODEL IS PROPERLY WIRED ACCORDING TO LOCAL AND NATIONAL ELECTRICAL CODES. IMPROPER ELECTRICAL INSTALLATION COULD

CAUSE DAMAGE TO PROPERTY AND MAY RESULT IN PERSONAL INJURY OR DEATH.

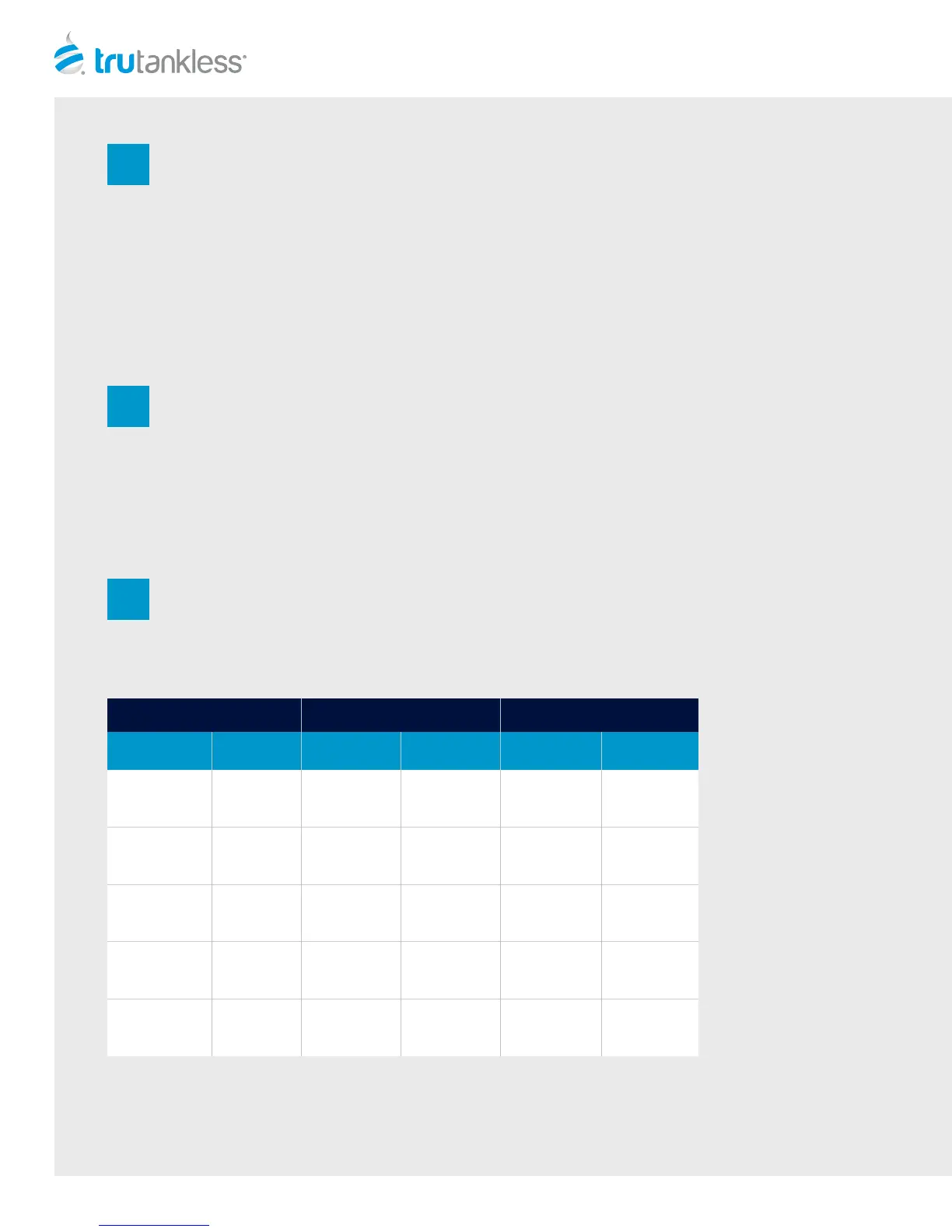

Model

Maximum

Amperage

Minimum

Breaker Size

Minimum

Wire Size

Minimum

Breaker Size

Minimum

Wire Size

TR36/TC33

160

2 x 80 Amp

2-Pole Breakers

4 x #4 Ga.

Copper

TR29/TC25

120

2 x 60 Amp

2-Pole Breakers

4 x #6 Ga.

Copper

1 x 125 Amp

2-Pole Breakers

2 x #2 Ga.

Copper

TR24/TC21

100

2 x 50 Amp

2-Pole Breakers

4 x #6 Ga.

Copper

1 x 100 Amp

2-Pole Breakers

2 x #2 Ga.

Copper

TR20/TC17

80

2 x 40 Amp

2-Pole Breakers

4 x #8 Ga.

Copper

1 x 80 Amp

2-Pole Breakers

2 x #4 Ga.

Copper

TR15/TC13

60

2 x 30 Amp

2-Pole Breakers

4 x #8 Ga.

Copper

1 x 60 Amp

2-Pole Breakers

2 x #6 Ga.

Copper

ELECTRICAL REFERENCE OPTION 1 OPTION 2

Loading...

Loading...