tained in compliance with this docu-

ment,aswellaswiththeapplicable

standardsoftheNationalFireProtec-

tion Association, in addition to the

standards of any other authorities

having jurisdiction. Failure to do so

may impair the integrity of these de-

vices.

The F690 Concealed Pendent Sprin-

klers mustnot be usedin applications

where the air pressure above the ceil-

ing is greater than that below. Down-

drafts through the Mounting Cup

could delay sprinkler operation in a

fire situation.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. The installing contractor or

manufacturer should be contacted

relative to any questions.

TECHNICAL DATA

The 1/2 inch (15 mm) orifice Model

F690 Concealed Pendent Sprinklers

are rated for use at a maximum service

pressure of 175 psi (12,1 bar). The

available temperature ratings and

nominal installation dimensions are

given in Figure A. Table 1 summarizes

the maximum permissible ceiling tem-

peratures for use with the F690.

Standard finishes for the Cover Plate

are satin chrome and painted white;

however, other factory painted finishes

for the Cover Plate are available on

special order.

The nominal discharge curves plotted

in Figure C represents the flow “Q” in

GPM (LPM) as determined by the for-

mula:

where the nominal sprinkler discharge

coefficient “K” = 5.6 (80,7); and “p” =

the residual flowing pressure in psi

(bar). Listing standards permit the ac-

tual value of “K” to vary from 5.3 to 5.8

(76,4 to 83,6); however for hydraulic

calculations, a K-factor of 5.6 (80,7) is

to be applied.

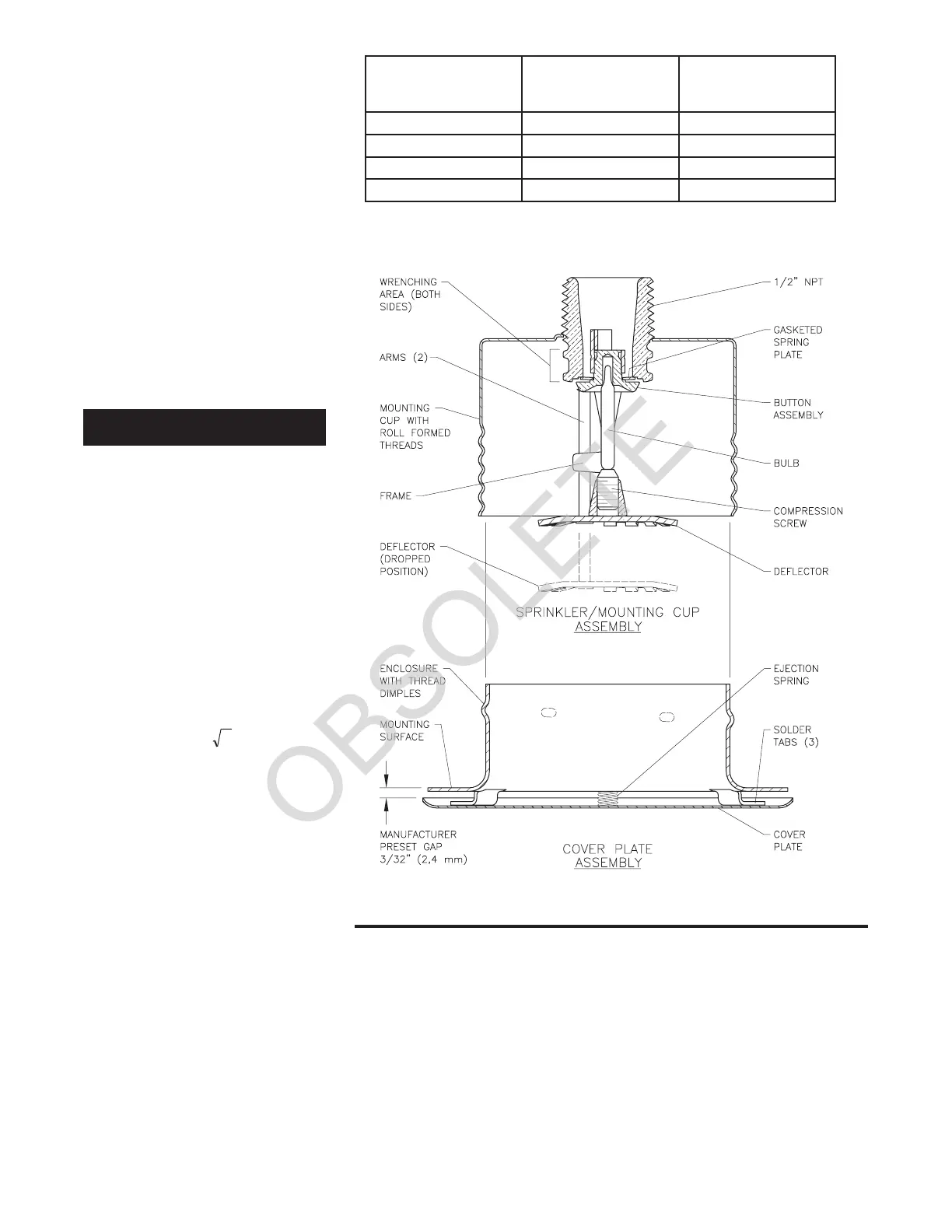

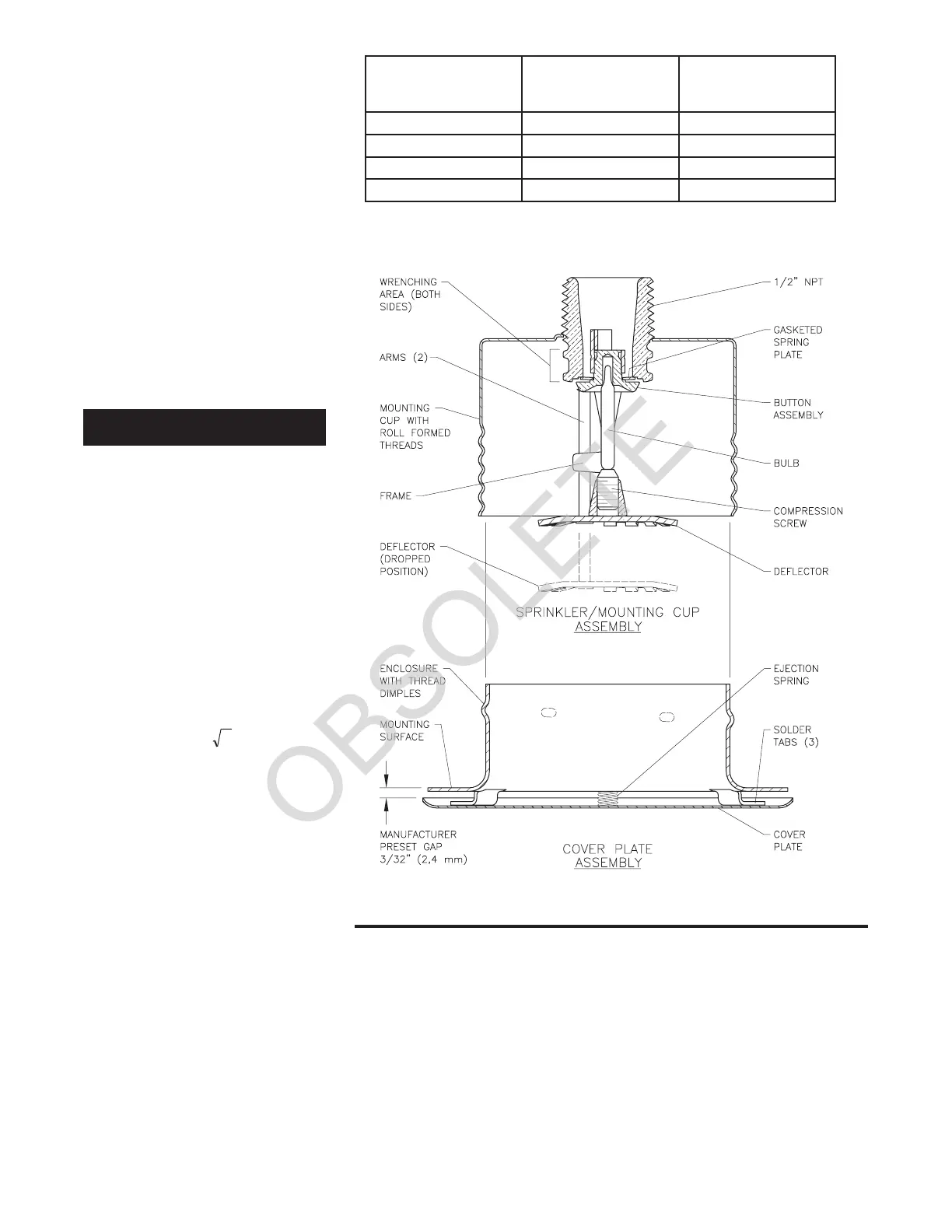

The F690 Sprinkler consists of two

sub-assemblies, as shown in Figure B:

the Sprinkler/Mounting Cup Assembly

and the Cover Plate Assembly.

Sprinkler/Mounting Cup Assembly

The Sprinkler Assembly utilizes a 3

mm Bulb and has a die-cast dezincifi-

cation resistant (DZR) bronze alloy

Frame. The two pieces of the Button

Assembly are constructed from brass

per ASTM B16 (C36000) and copper

(C12200). The Gasketed Spring Plate

consists of an Beryllium Nickel

(N03360) disc spring that is sealed on

both its inside and outside edges with

aTeflon† gasket. The Compression

Screw is brass per ASTM B16

(C36000). The Deflector is bronze per

ASTM B36 (C22000), the Arms are

phosphor bronze per CDA Alloy 510.

The Mounting Cup is chrome plated

low carbon sheet steel.

The Mounting Cup Assembly is pro-

vided with a Protective Cap (Ref. Fig-

ure E), which helps prevent damage to

the Deflector and Arms before the

Cover Plate Assembly is installed.The

Protective Cap is designed such that

the Cap can be opened to expose the

sprinkler for temporary fire protection,

until the ceiling installation is com-

pleted and the Cover Plate can be in-

stalled. The Protective Cap is dis-

carded once the Cover Plate Assembly

is installed.

Cover Plate Assembly

The Cover Plate Assembly, which

screws onto the Sprinkler/Mounting

Cup Assembly, consists of a Cover

Plate which is soldered to an Enclo-

sure at three equidistant locations

around their peripheries. The Cover

Plate and Enclosure are brass per

ASTM B36 (C26000 or C26800). A

Type 302 stainless steel compression

Spring is located between the flange of

QKp

=

SPRINKLER

TEMPERATURE

RATING

COVER PLATE

TEMPERATURE

RATING

MAXIMUM

CEILING

TEMPERATURE

135°F / 57°C

200°F / 93°C

135°F / 57°C

135°F / 57°C

100°F / 38°C

100°F / 38°C

TABLE 1

SUMMARY OF MAXIMUM PERMITTED CEILING TEMPERATURE RATINGS

155°F / 68°C

175°F / 79°C 165°F / 74°C

165°F / 74°C

150°F / 68°C

150°F / 68°C

FIGURE B

MODEL F690 QUICK RESPONSE

CONCEALED PENDENT SPRINKLER ASSEMBLY

† DuPont Registered Trademark

Loading...

Loading...