12

5

3

4

1mm

23

18

0.5mm

1

2

3

9

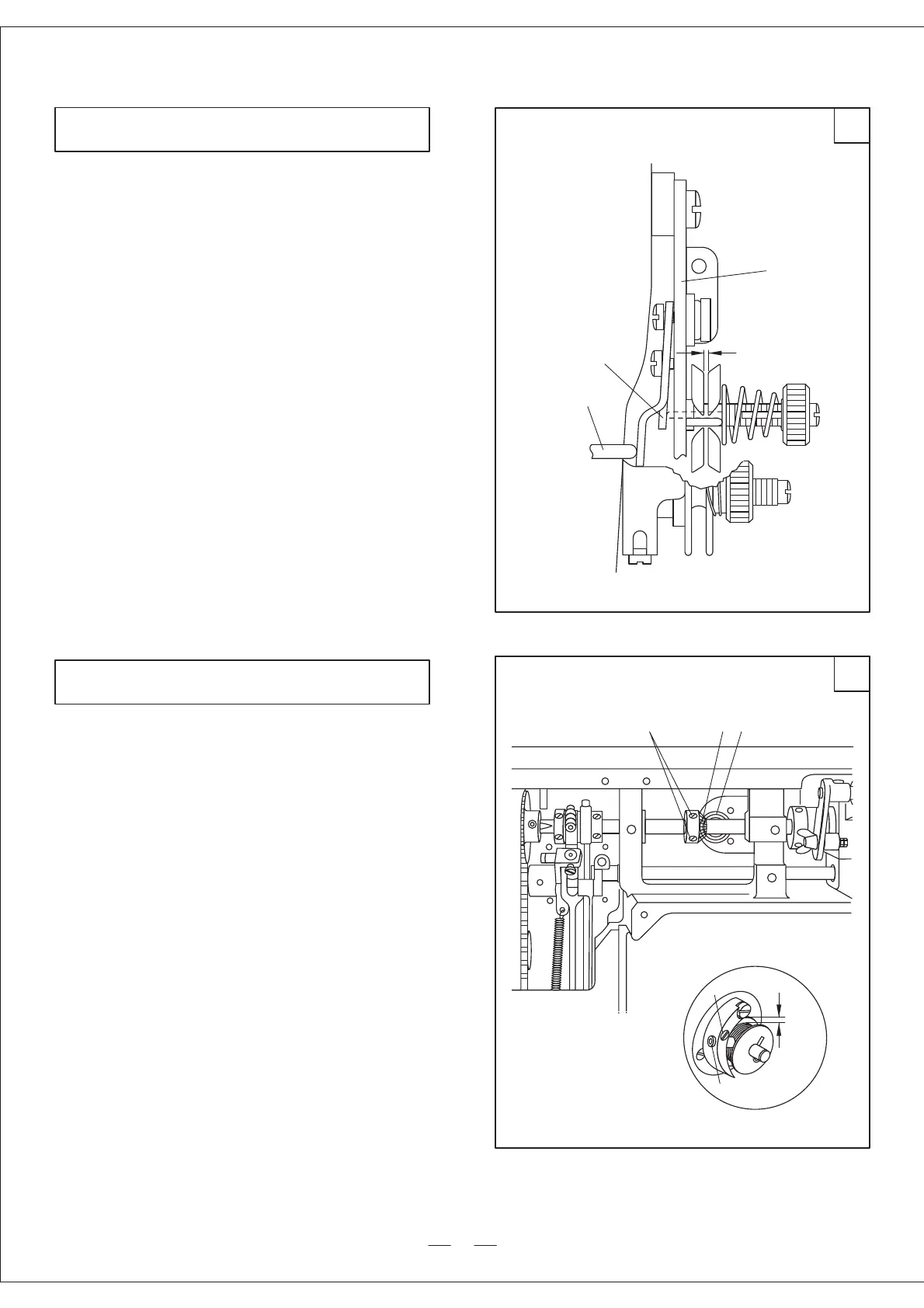

23. Needle thread tension release (Fig.23)23. Needle thread tension release (Fig.23)

When the presser foot is lifted, the clearance

between the two tension discs should be 0.5mm

( 0.5mm is the minimum. When applied to thick

thread, it could be adjusted to 1 mm or more).Adjust

the plate 1 as required.

When the presser foot is lifted, the clearance

between

the two tension discs should be 0.5mm

(

0.5mm is the minimum. When applied to thick

thread,

it could be adjusted to 1 mm or more).Adjust

the

plate 1 as required.

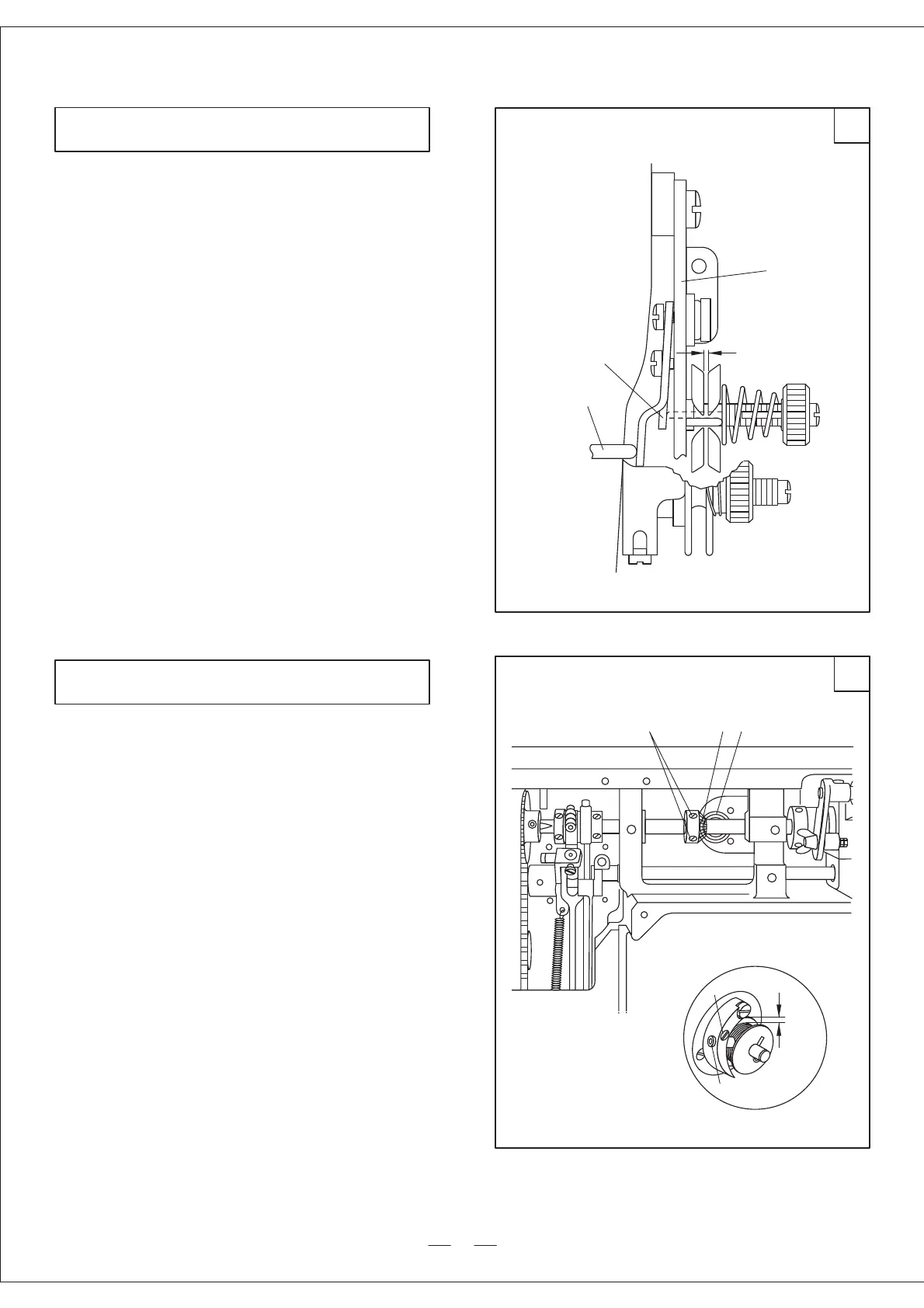

24. Bobbin thread winder (Fig.24)24. Bobbin thread winder (Fig.24)

1. When the winder switch on, its spindle must

engage reliable; when the winder switch off, the

friction wheel 5 and the driving gear 1 should get

apart;

2. When the thread level is approx. 1mm from the

edg of the bobbin, the winder will switch off

automatically;

3. When operating, set the bobbin on the winder,

threading the bobbin thread and switch the winder

On, adjust the pin 3 and screw 4 as requirements

if need.

1. When the winder switch on, its spindle must

engage

reliable; when the winder switch off, the

friction

wheel 5 and the driving gear 1 should get

apart;

2. When

the thread level is approx. 1mm from the

edg

of the bobbin, the winder will switch off

automatically;

3. When

operating, set the bobbin on the winder,

threading

the bobbin thread and switch the winder

On,

adjust the pin 3 and screw 4 as requirements

if

need.

Loading...

Loading...