NINA-W1 series - System integration manual

UBX-17005730 - R11 Handling and soldering Page 44 of 55

C1 - Public

Handling and soldering

No natural rubbers, hygroscopic materials or materials containing asbestos are employed.

4.1 Packaging, shipping, storage and moisture preconditioning

For information pertaining to reels, tapes or trays, moisture sensitivity levels (MSL), shipment and

storage, as well as drying for preconditioning refer to NINA-W1 series Data Sheets [2]/[3]/[4],

and u-

blox Package Information Guide [5].

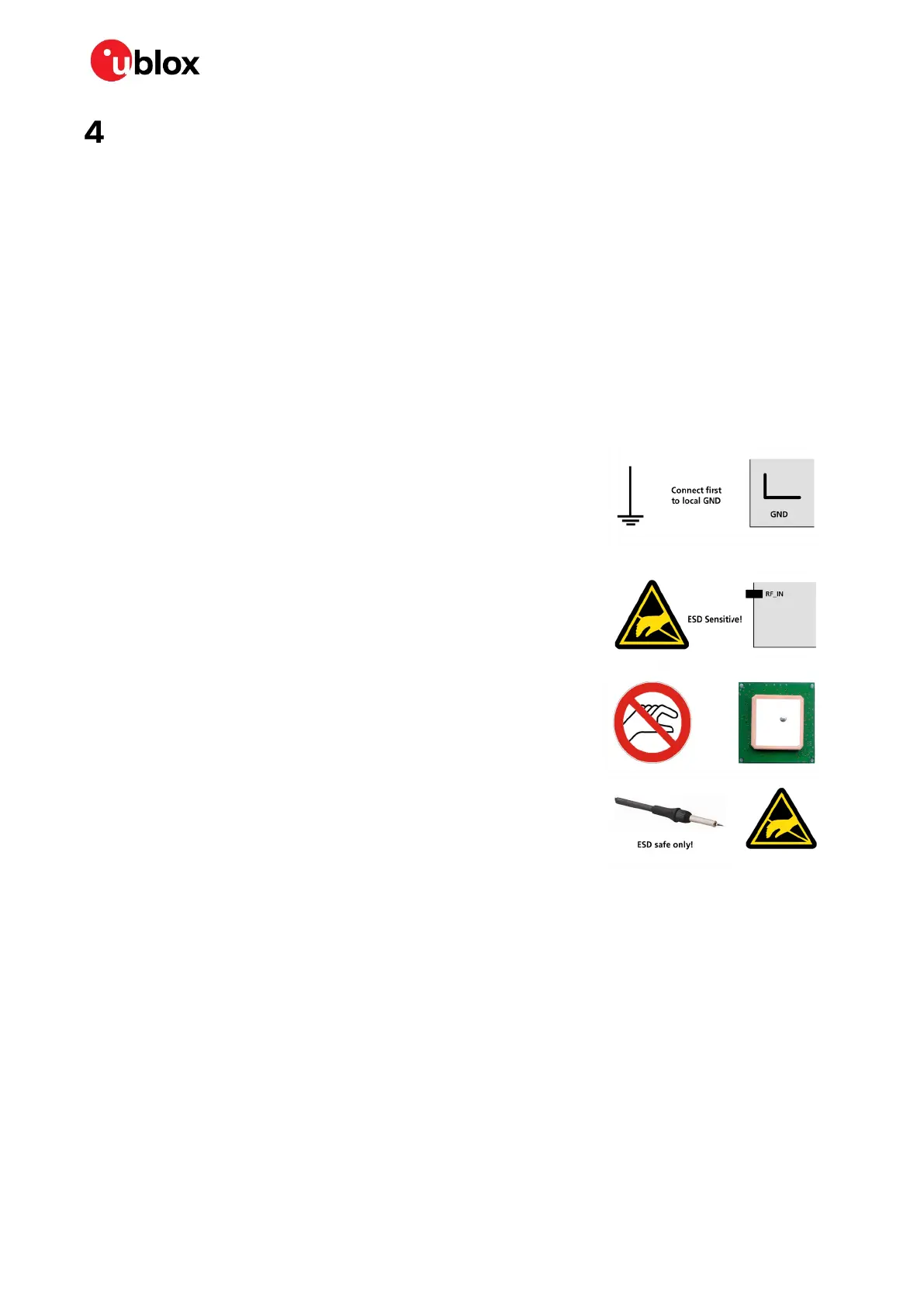

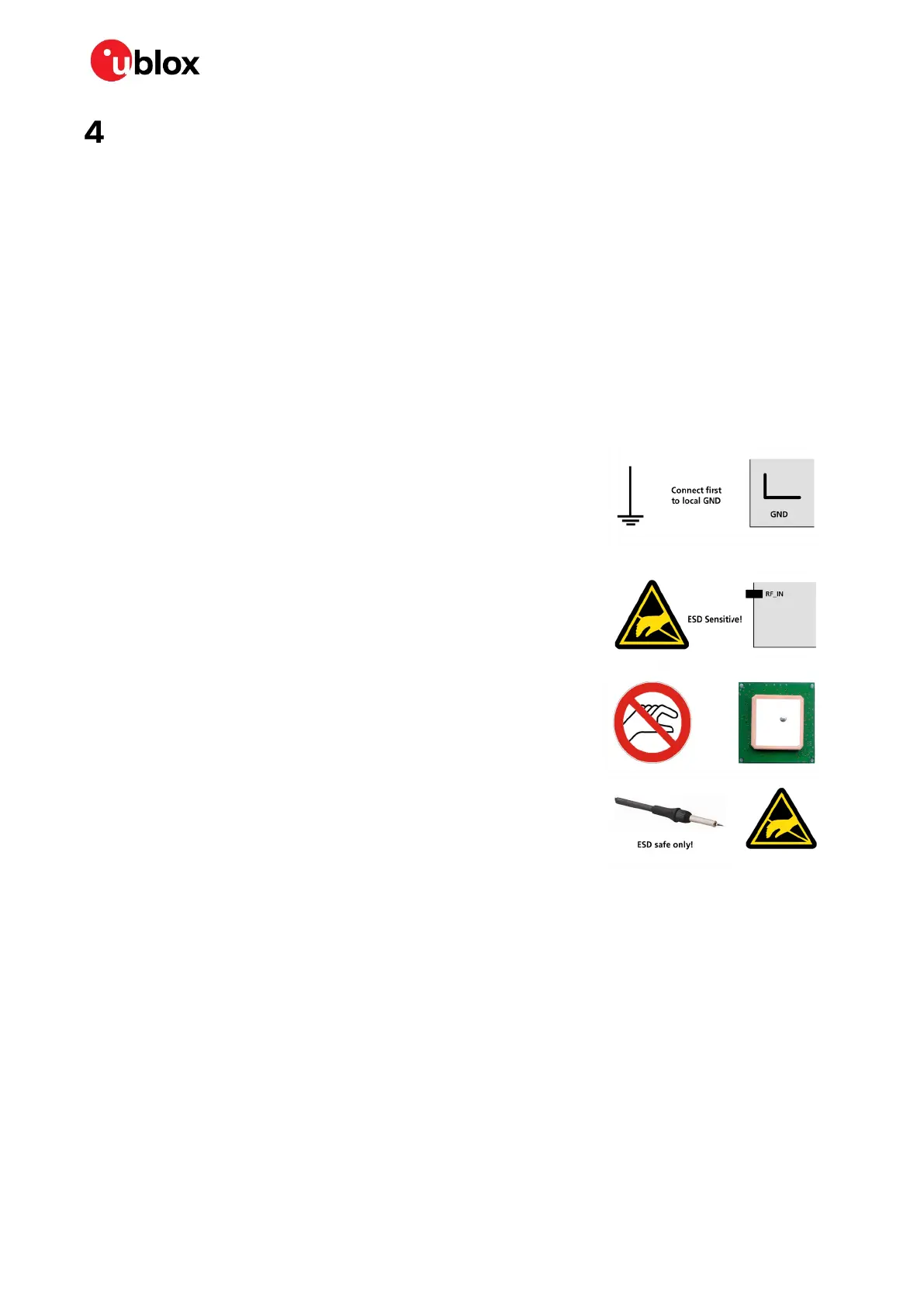

4.2 Handling

The NINA-W1 series modules are Electro-Static Discharge (ESD) sensitive devices and require special

precautions during handling. Particular care must be exercised when handling patch antennas, due to

the risk of electrostatic charges. In addition to standard ESD safety practices, the following measures

should be taken into account whenever handling the receiver:

Unless there is a galvanic coupling between the local

GND (i.e. the work table) and the PCB GND, then the

first point of contact when handling the PCB must

always be between the local GND and PCB GND.

• Before mounting an antenna patch, connect ground

of the device

When handling the RF pin, do not come into contact

with any charged capacitors and be careful when

contacting materials that can develop charges (e.g.

patch antenna ~10 pF, coax cable ~50-

soldering iron, …)

To prevent electrostatic discharge through the RF

input, do not touch any exposed antenna area. If there

is any risk that such exposed antenna area is touched

in non ESD protected work area, implement proper

ESD protection measures in the design.

When soldering RF connectors and patch antennas to

the receiver’s RF pin, make sure to use an ESD safe

soldering iron (tip).

4.3 Soldering

4.3.1 Reflow soldering process

The NINA-W1 series modules are surface mount modules supplied on a FR4-type PCB with gold plated

connection pads and are produced in a lead-free process with a lead-free soldering paste. The bow

and twist of the PCB is maximum 0.75% according to IPC-A-610E. The thickness of solder resist

between the host PCB top side and the bottom side of the NINA-W1 series module must be considered

for the soldering process.

The module is compatible with industrial reflow profile for RoHS solders. Use of "No Clean" soldering

paste is strongly recommended.

The reflow profile used is dependent on the thermal mass of the entire populated PCB, heat transfer

efficiency of the oven, and particular type of solder paste used. The optimal soldering profile used has

to be trimmed for each case depending on the specific process and PCB layout.

Loading...

Loading...