Page|6

UIM2501

UI Robot Technology Co. LTD M25020101008EN

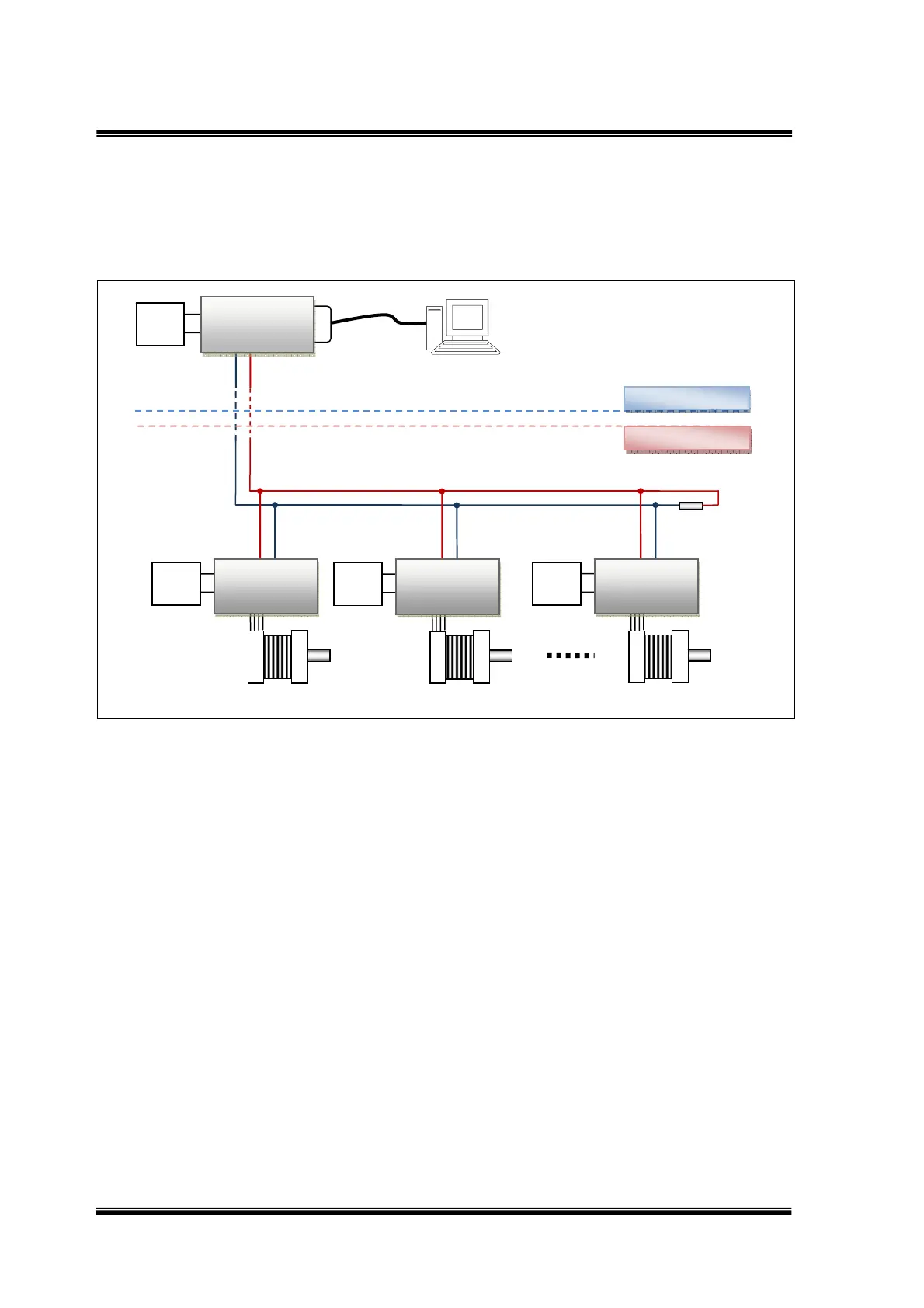

Network Operation

Multiple UIM242XX controllers can be wired together to form a reliable motor network.

Following figure provides a typical network wiring solution.

Figure 0-4: Wiring Scheme for Network Operation

Notice:

In multi-node CAN applications, it is important to maintain a direct point-to-point wiring

scheme. A single pair of wires should connect each element of the CAN bus, and the two

ends of the bus should be terminated with 120Ω resistors. A star configuration should never

be used.

UIM2501 converter has a build-in terminal resistor. To enable the UIM2501 converter’s

terminating resistor, please toggle the DIP8 to ON position. User only needs to attach a

resistor at the UIM242 end of the bus.

In addition, any deviation from the point-to-point wiring scheme creates a stub. The high-

speed edge of the CAN data on a stub can create reflections back down the bus. These

reflections can cause data errors by eroding the noise margin of the system. Although stubs

are unavoidable in a multi-node system, care should be taken to keep these stubs as small

as possible.

RS232

Motor#1

6‐40

VDC

Power

CANH

CANL

CANH

CANL

120Ohm

CANH

CANL

Factory

ControlRoom

UIM250

Controller

12‐40

VDC

Power

UIM242xx

Controller1

Motor#2

CANH

CANL

12‐40

VDC

Power

UIM242xx

Controller1

Motor#100

CANH

CANL

12‐40

VDC

Power

UIM242xx

Controller1

Loading...

Loading...