32

The b oilers are produced for the typ e of gas specif-

ically requested upon ordering.

DANGER!

The conversion for the operation of

the b oiler w ith a type of gas other

than that specicall required in the

order, must b e performed b y Unical

professionall qualied personnel, in compliance

w ith the standards and regulations in force.

The manufacturer cannot b e held liab le for any

damage resulting from a conversion operation

that is incorrect or not performed in compliance

w ith the law s in force and/or w ith the instructions

given.

ATTENTION!

After performing the conversion for

the operation of the b oiler w ith a type

of gas ( e.g. propane gas) other than

that specicall requested when or-

dering, the appliance will onl wor

w ith this new type of gas.

ATTENTION!

Indications for propane gas-red ap-

pliances

Mae sure that the gas tan has been

deaerated b efore installing the appli-

ance.

For state-of-the-art deaeration of the

tan, contact the LPG supplier or a

person qualied in compliance with

law .

If the tan has not been professionall

deaerated, ignition prob lems could

arise.

In that case, contact the supplier of

the LPG tan.

To convert the b oiler from one type of gas to

another, proceed as follows:

- Disconnect the appliance from the elctrical power

supply

- disconnect the detection/switch-on electrode ( 1),

loosen the 4 screws ( 2) that connects the b urner

1

2

3

4.3 - ADAPTATION

TO THE USE OF OTHER GAS

pack ( 3) to the nozzl e collector

- remove the b urner ( 3);

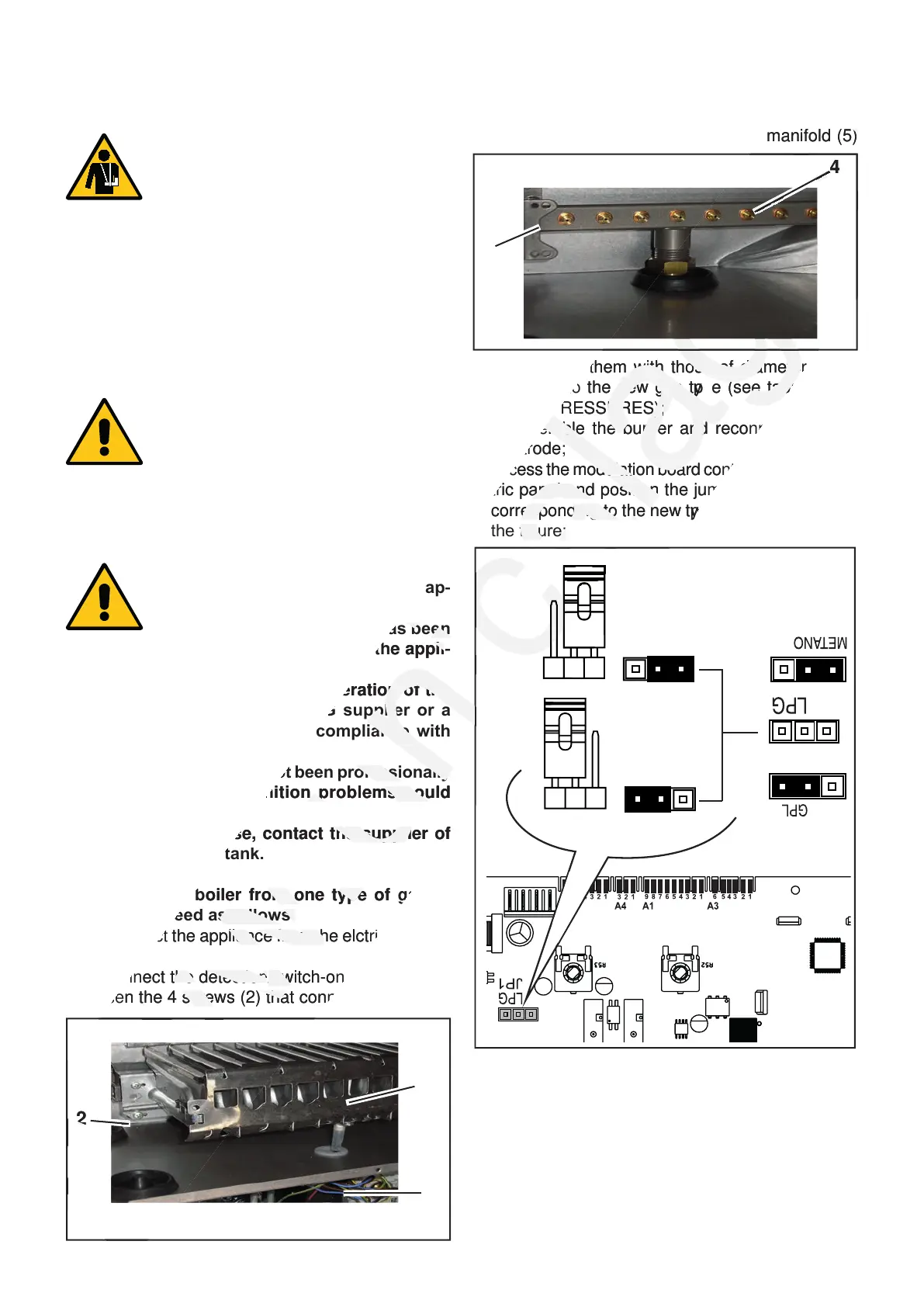

- disconnect the nozzl es ( 4) from the manifold ( 5)

and replace them with those of diameter corre-

sponding to the new gas typ e ( see tab le " NOZ-

ZLES - P RESSURES);

- re-assemb le the b urner and reconnect it to the

electrode;

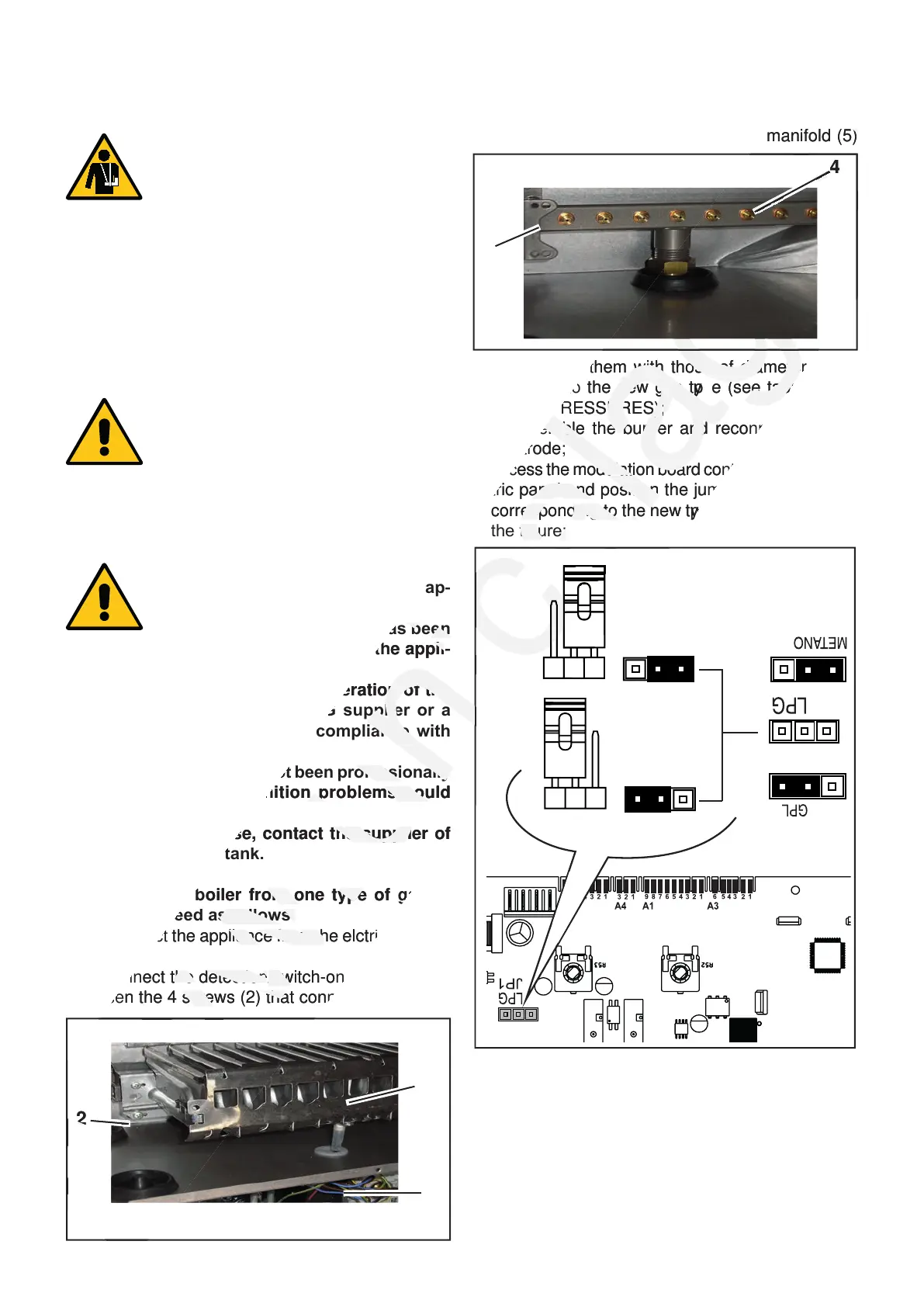

- access the modulation b oard contained in the elec-

tric panel and position the j umper in the position

corresponding to the new typ e of gas indicated in

the gure;

5

4

- Close the electric panel and restore the appliances

electric power supply

- check the pressure v alue upstream of the gas

va lve ( see tab le “ NOZZLES - P RESSURE” ) and

adj ust the pressure as indicated in paragraph

“ 3.12” ;

- check that the b urner is worki ng properly;

- check that there are no gas leaks.

Indications for propane gas-red ap

www.unicalag.ru

Indications for propane gas-red ap

Mae sure that the gas tan has been

www.unicalag.ru

Mae sure that the gas tan has been

deaerated b efore installing the appli

www.unicalag.ru

deaerated b efore installing the appli

For state-of-the-art deaeration of the

www.unicalag.ru

For state-of-the-art deaeration of the

tan, contact the LPG supplier or a

www.unicalag.ru

tan, contact the LPG supplier or a

person qualied in compliance with

www.unicalag.ru

person qualied in compliance with

If the tan has not been professionall

www.unicalag.ru

If the tan has not been professionall

deaerated, ignition prob lems could

www.unicalag.ru

deaerated, ignition prob lems could

In that case, contact the supplier of

www.unicalag.ru

In that case, contact the supplier of

the LPG tan.

www.unicalag.ru

the LPG tan.

To convert the b oiler from one type of gas to

www.unicalag.ru

To convert the b oiler from one type of gas to

another, proceed as follows:

www.unicalag.ru

another, proceed as follows:

Disconnect the applianc

www.unicalag.ru

Disconnect the applianc

e from the elctrical power

www.unicalag.ru

e from the elctrical power

disconnect the detection

www.unicalag.ru

disconnect the detection

/switch-on electrode ( 1),

www.unicalag.ru

/switch-on electrode ( 1),

loosen the 4 screws ( 2) that connects the b urner

www.unicalag.ru

loosen the 4 screws ( 2) that connects the b urner

disconnect the nozzl es ( 4) from the manifold ( 5)

www.unicalag.ru

disconnect the nozzl es ( 4) from the manifold ( 5)

and replace them with those of diameter corre

www.unicalag.ru

and replace them with those of diameter corre

sponding to the new gas typ e ( see tab le " NOZ

www.unicalag.ru

sponding to the new gas typ e ( see tab le " NOZ

ZLES - P RESSURES);

www.unicalag.ru

ZLES - P RESSURES);

re-assemb le

www.unicalag.ru

re-assemb le

the b urner and reconnect it to the

www.unicalag.ru

the b urner and reconnect it to the

electrode;

www.unicalag.ru

electrode;

cess the modulation b oard contained in the elec

www.unicalag.ru

cess the modulation b oard contained in the elec

tric panel and position the j umper in the position

www.unicalag.ru

tric panel and position the j umper in the position

corresponding to the new typ e of gas indicated in

www.unicalag.ru

corresponding to the new typ e of gas indicated in

the gure;

www.unicalag.ru

the gure;

Loading...

Loading...