Bulletin 30-020.007

Copyright © 2019 Unico Inc. Page 20

Figure 27. Tighten Pressure Tube Nut

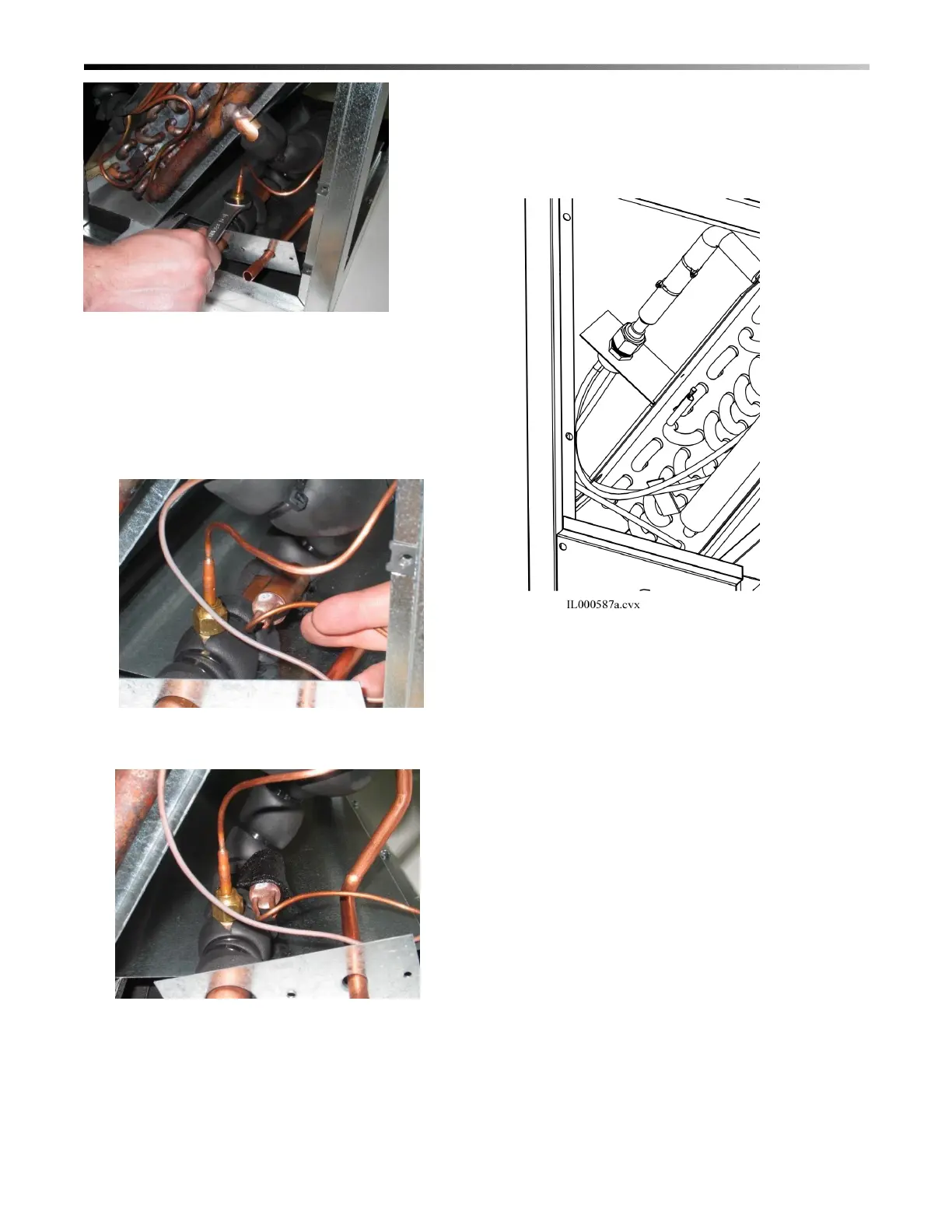

4. Locate the bulb on a horizontal straight section of

the suction line (Figure 28). Attach the bulb to the

tubing with clamp provided and wrap with two

pieces of cork tape (Figure 29). For satisfactory

expansion valve control, good thermal contact

between the bulb and the suction line is essential.

Figure 28. Thermal Measuring Bulb Placed on

Copper Tube.

Figure 29. Bulb Secure Clamp and Cork Tape

5. After all lines have been connected, pressure

check the connections by charging the system

with 150 psig of dry nitrogen and check for leaks

at all connections.

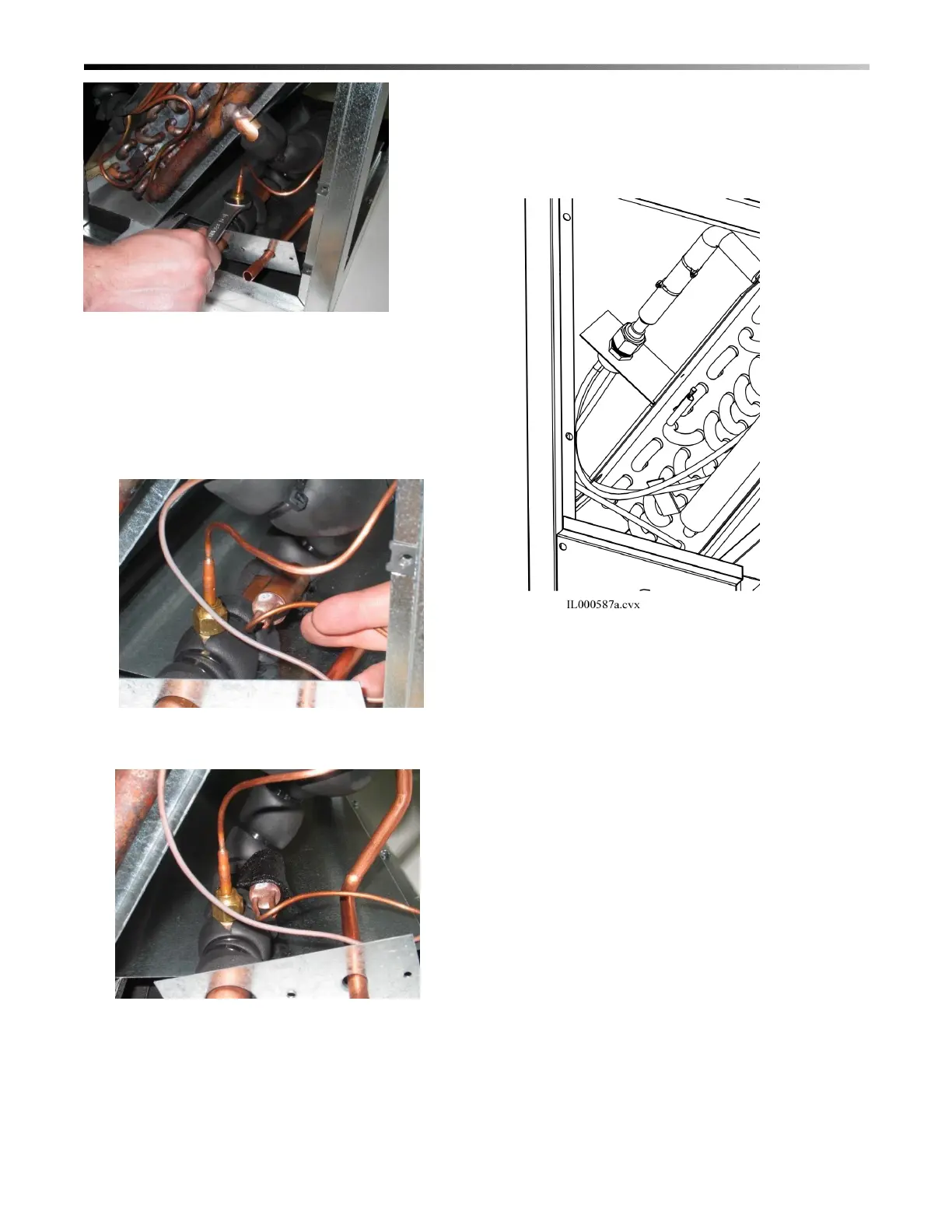

STEP 4 CONNECT SMALL TUBE

(ISERIES ONLY)

For the iSeries coil, connect the small tube directory

to the distributor, where the TXV would normally be

located (Figure 30).

Figure 30. Attach and tighten connection nut

straight to distributor (iSeries coils only)

STEP 5. CONNECT THE LINE SET.

Braze the line sets to the copper stubs or connect to the

flare. If brazing, use a nitrogen purge and protect the

expansion valve by wrapping it with a wet cloth. For

threaded flare fittings, use 1 or 2 drops of refrigerant

oil on the flare (not on the threads) and tighten per the

torque specified in the iSeries manual.

Water Coil Connections. If you are installing the hot

water coil, remove the side coil access panel and cut

away the insulation. Slide the coil into the cabinet and

secure with brackets supplied with the hot water coil.

Install the access panel after the coil is in place.

All water connections are 7/8-inch (22mm) sweat OD

connections. Sweat the water connections, then fill the

system. Bleed the air from the coil by backing off the

screw inside the bleed valve for venting (Fig. 31).

If unit is in an unconditioned space below freezing,

care must be taken not to freeze the water in the coil.

The best method is to use a glycol-water antifreeze

solution with a freezing point below the coldest

temperature expected.

Loading...

Loading...