Bulletin 30-020.007

Copyright © 2019 Unico Inc. Page 26

Using a Low Ambient Control Kit. Since the Unico

System operates at colder coil temperatures (in cooling

mode), an anti-frost switch is installed on the coil to

prevent coil freeze-up. In certain instances, such as

when the outdoor ambient temperature is low, the

condensing unit will cycle on the anti-frost switch.

This may reduce the cooling capacity at a time when

the cooling load is still fairly high. To provide better

control and comfort, install a low ambient control on

the condensing unit. Typically, a low ambient control

is necessary when operating the unit at outdoor

temperatures below 80°F (26.6 °C), especially for a 5-

ton nominal capacity system.

These controls come in different configurations such as

the Hoffman Controls Corp. series 800AA-head

pressure control. This control modulates the outdoor

fan to maintain a minimum liquid line temperature.

Other controls may cycle the fan on/off. In either case

check with the condensing unit manufacturer to

determine what controls are compatible with the

condensing unit.

MAINTENANCE (1218, 2430, 3036, 3642,

4860)

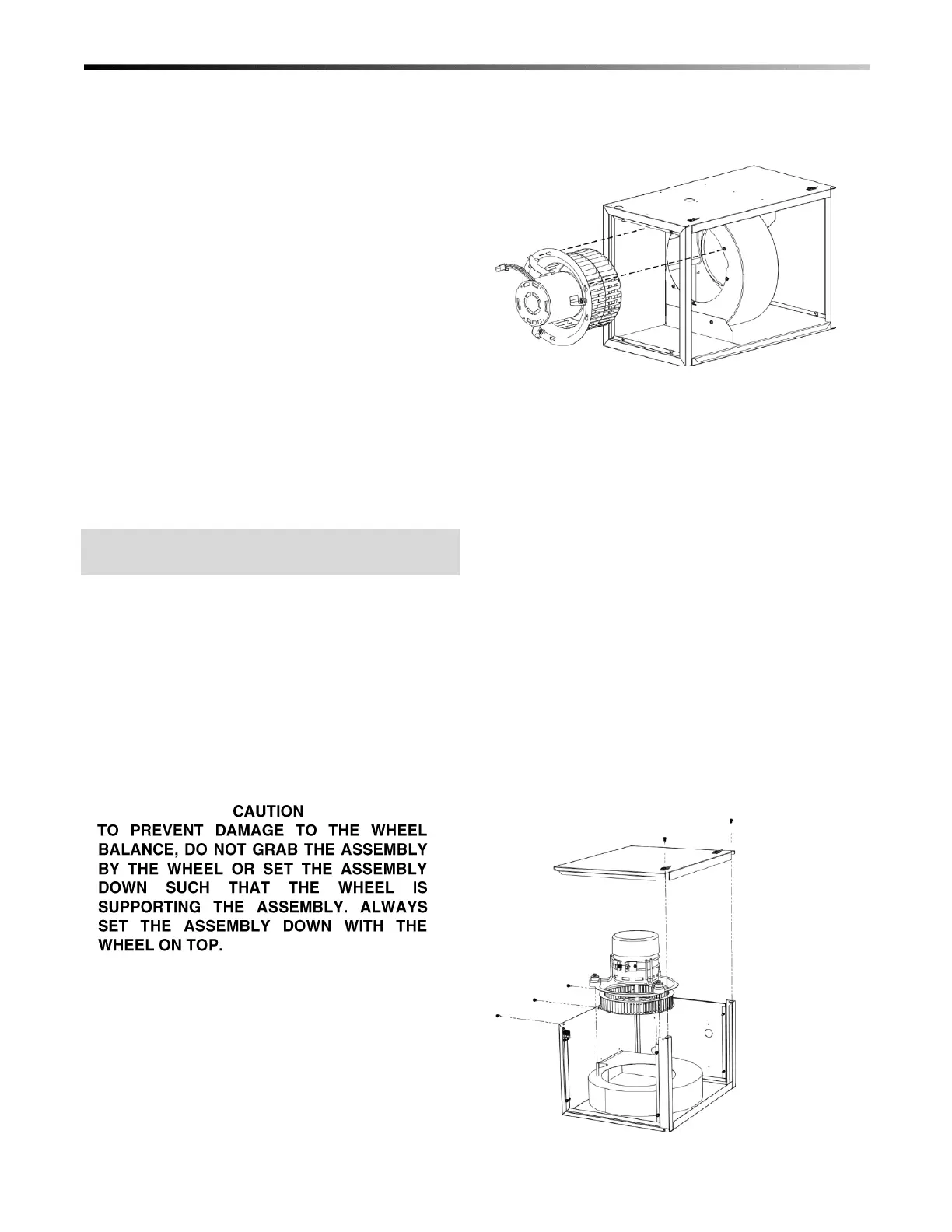

When service is required to the motor or the wheel, the

entire assembly may be removed as a unit (see Figure

34). The blower assembly unit is accessible from the

piping side of the unit. It is not necessary to disconnect

any module or ducting.

To remove the motor and blower wheel assembly,

loosen the six (6) screws fastening the motorized

blower assembly to the blower housing. Twist the

motorized blower assembly counter-clockwise (CCW)

and pull the assembly away from the blower housing.

Once the assembly is removed, the proper service may

be performed. If the wheel is to be changed, it may

simply be removed from the motor shaft by loosening

the motor set screw and pulling the blower wheel off

the motor shaft. If the motor is to be changed, first the

blower wheel must be removed as mentioned above,

and then the screws fastening the motor to the inlet ring

must be removed.

To re-install the motorized blower assembly back into

the blower housing, follow the steps mentioned above

in reverse order. It is not necessary to access both

sides of the unit to remove motor.

Figure 34. Removal of the Motorized Blower

Assembly

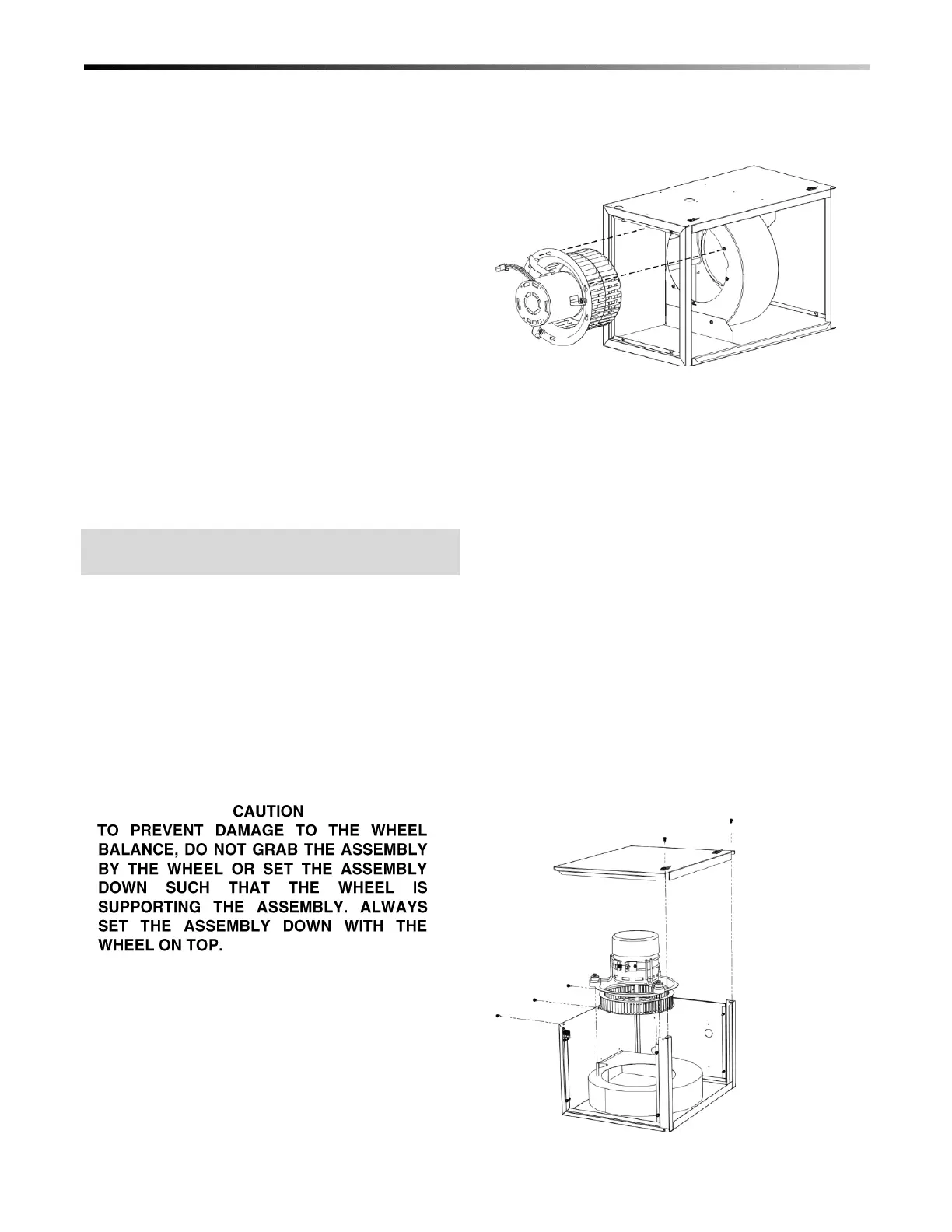

Maintenance (1218). To remove the M1218 blower

assembly, loosen and remove the five (5) screws

securing the top blower module plate. Remove the

three (3) nuts, lock washers, and flat washers securing

the blower assembly to the blower wheel housing.

Carefully lift the motor, wheel, inlet ring, and motor

mounting ring off the threaded pins attached to the

blower wheel housing.

If the wheel is to be changed, it may simply be removed

from the motor shaft by loosening the motor set screw

and pulling the blower wheel off the motor shaft. If the

motor is to be changed, first the blower wheel must be

removed as mentioned above, and then loosen the

screw in the motor belly band holding the motor in

place.

To re-install the motorized blower assembly back into

the blower housing, follow the steps mentioned above

in reverse order. It is not necessary to remove the

door panels to remove the motor.

Figure 35. Removal of M1218 Motorized Blower

Assembly

Loading...

Loading...