ALTERNATOR/REGULATOR TEST PROCEDURE

General

It

is desirable to test the charging system (alternator and voltage regulator) in the vehicle using the

vehicle wiring harness and electrical loads that are a permanent part of the system. In-vehicle

testing will then provide the technician with

an

operational test of the charging system

as

well

as

the major components of the electrical system.

Preliminary Checks & Tests

Before starting the

actual electrical test procedure, the charging system, battery and wiring should

be

checked to eliminate possible problem areas. The following procedure is recommended:

1.

Check the condition and adjustment of belts.

A.

If the alternator fan can

be

moved by pushing on a fan blade with your finger, the belts

should

be

adjusted.

B.

Replace any worn or glazed belts.

2.

Check

to

see that all terminals, connectors and plugs are clean and tight.

A.

Loose or corroded connections cause high resistance and this could cause

overcharging, undercharging or damage to the charging system.

B.

Badly corroded battery cables could prevent the battery from reaching a fully charged

condition.

3.

Check battery condition and change if necessary. A low or discharged battery may cause

false or misleading readings

on

the in-vehicle tests.

Test Equipment Requirements

The

Alternator and Regulator tests outlined require electrical test equipment to measure voltage

only;

however, most commercial test equipment incorporates several testing devices in a single

unit.

DC

VOLTMETER: 0-20 Volt Scale

BATTERY

TEST

EQUIP.:

Any commercial type, Hydrometer with temperature correction scale.

Storage

Battery

The

vehicle storage battery circuit represents a continuous although variable electrical load to the

alternator. If the circuit,

pOSition

or negative, is opened or broken while the alternator is charging,

the

loss of the battery will result

in

the charging voltage rising to unsafe levels.

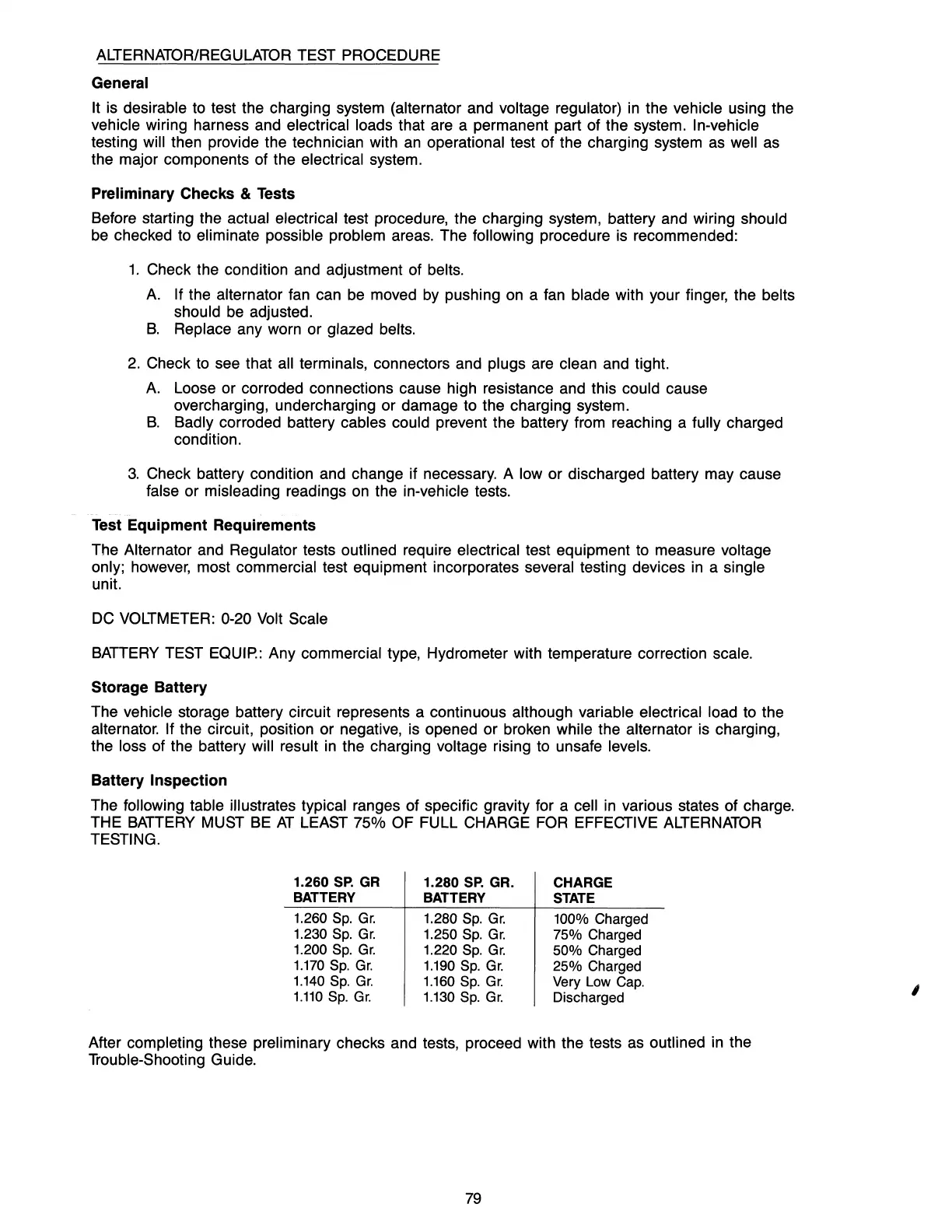

Battery Inspection

The following table illustrates typical ranges of specific gravity for a cell in various states of charge.

THE

BATTERY

MUST

BE

AT

LEAST 75% OF FULL CHARGE

FOR

EFFECTIVE

ALTERNATOR

TESTING.

1.260

SP.

GR

1.280

SP.

GR.

CHARGE

BATTERY

BATTERY

STATE

1.260 Sp.

Gr.

1.280

Sp.

Gr.

100% Charged

1.230

Sp.

Gr.

1.250

Sp.

Gr.

75%

Charged

1.200

Sp.

Gr.

1.220

Sp.

Gr.

50%

Charged

1.170

Sp.

Gr.

1.190

Sp.

Gr.

25%

Charged

1.140

Sp.

Gr.

1.160

Sp.

Gr.

Very Low Cap.

1.110

Sp.

Gr.

1.130 Sp.

Gr.

Discharged

After completing these preliminary checks and tests, proceed with the tests

as

outlined in the

Trouble-Shooting Guide.

79

I

Loading...

Loading...