ENGINE

COOLING

CIRCUIT

Changing

the

Raw

Water

Impeller

1. Close the raw water intake,

2. Remove the inlet and outlet

rx>rt

hoses from the pump,

noting the port location and positioning.

3. Remove the pump assembly and its gasket from the

engine.

4. Remove the three hex head

screws

that hold the housing

to the cover.

5. Tap

the

housing/cover assembly on its side to loosen and

separate the cover from its housing.

6. Remove the cover and its

O-ring and remove

the

impeller

gasket and plate.

7. Remove the retaining ring (circ1ip) and

pry

out the

impeller. Take care not to lose the key

off

the shaft's key-

way.

ACAUTION:

If

any

of

the

vanes

have

broken

off

the

impeller

they

must

be

found

to

prevent

blockage

in

the

cooling

circuit.

They

often

can

be

found

in

the

heat

exchanger.

8. Replace the gasket, impeller, and O-ring.

9. Apply a film

of

petroleum jelly

or

silicone

to

the inner

surface

of

the impeller housing.

NOTE:

Just coat the surface, do not over apply.

10. Install the

cover

housing

over

impeller.

11. Install the three hex

screws

and tighten.

15

12. Mount the pump to the engine taking care thai the end

seal and gasket are

in

place.

Do

not tighten the pump

mounting screws, just finger tight.

13.

Rca<;semhlc the hose connections and open the raw

water

intake.

14.

Start the engine

in

idle, this will allow the

pump

to align

itself with its drive shaft.

15.

Stop

the engine and tighten the

pump

assembly mount-

ing screws.

16.

Start and run the engine, check for leaks and check for a

norrnal operating temperature.

NOTE:

Should a failure occur with the pumps internal parts

(seals and bearings)

it

may be more cost efficient

to

purchase

a new pump. The price

of

individual parts would almost

match the price

of

a new pump.

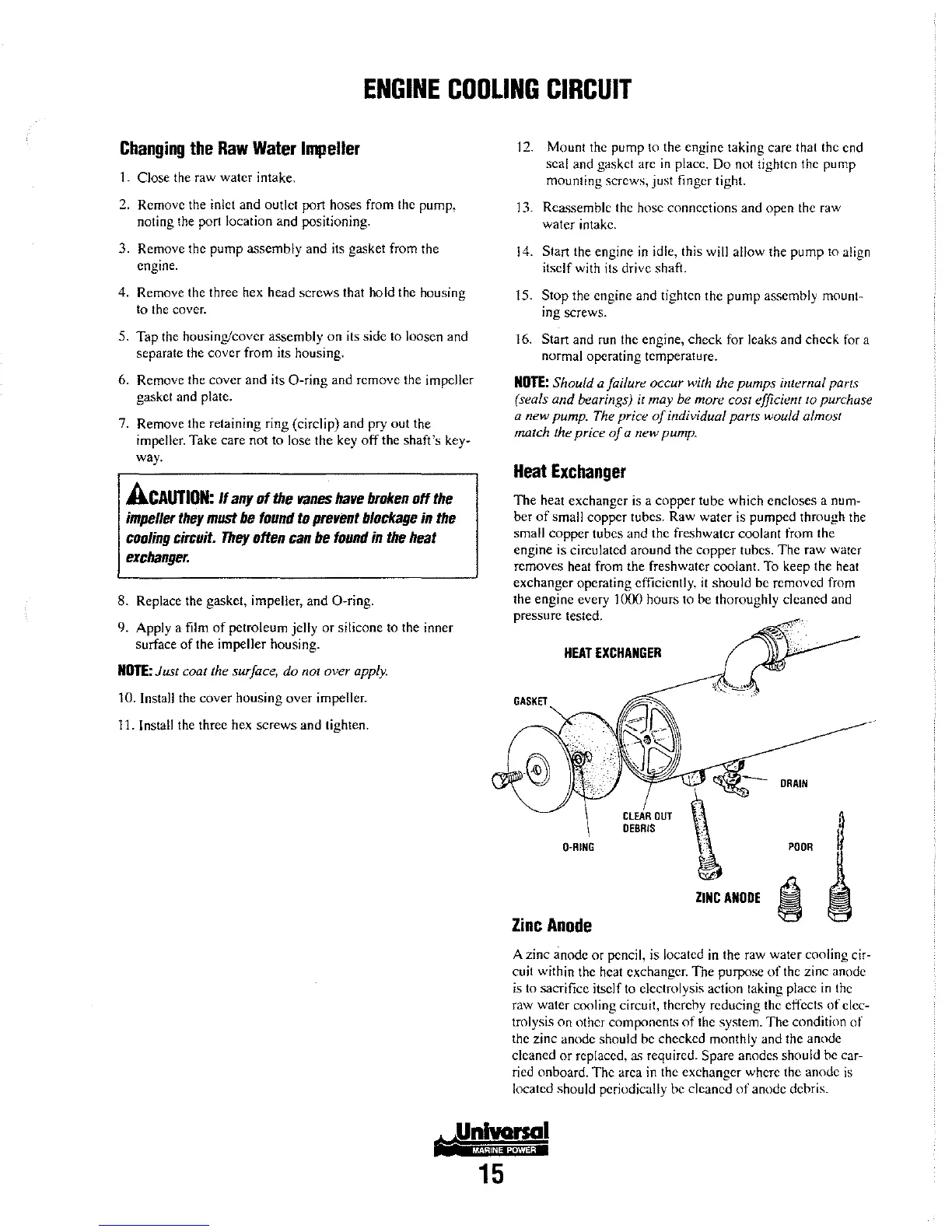

Heat

Exchanger

The

heat exchanger is a copper

tUhe

which encloses a num-

ber

of

small copper tubes. Raw water is pumped through the

small

copper

tubes and the freshwater coolant from the

engine is circulated around the

copper

tubes.

The

raw water

removes heat from the freshwater coolant. To keep the heat

exchanger operating efficiently,

it

should be removed from

the engine every 1000 hours to be thoroughly cleaned and

pressure tested.

HEAT

EXCHANGER

O-RING

Zinc

Anode

CLEAR

OUT

DEBRIS

DRAIN

POOR

ZINC

ANODE

i

A zinc anode

or

pencil, is located

in

the raw water cooling cir-

cuit within the heat

exchanger.

The

purpose

of

the zinc anode

is

to sacrifice itself to electrolysis action taking place

in

the

raw water cooling circuit, therehy reducing the effects

of

elec-

trolysis

on

other components

of

the system.

The

condition

of

the zinc anode should be checked monthly and the anode

cleaned

or

replaced,

a<;

required. Spare anodes should he car-

ried onboard.

The

area in the exchanger where the anode

is

located should periodically he cleaned

of

anode dehris.

Loading...

Loading...