HBW

TRANSMISSION

A

WARNING:

The

position

of

the

cover

plate

under-

neath

the

actuating

lever

is

factory-adjusted

to

ensure

equal

shift

lever

travel

from

neutral

position

to

A

and

B.

If

this

side

shift

cover

is

removed

or

in

any

way

tam-

pered

with,

the

transmission

warranty

will

be

void.

Authorized

Hurth

personnel

only

may

adjust

or

remove

this

cover.

NOTE:

When installing the gearbox, make cenain that shifting

is

not impeded by restricted movability

of

the Bowden cable

or

rod linkage,

by

unsuirabl:..,-'

positioned guide sheaves, too

small a bending radius, etc.

A shift cable attachment is pro-

vided with each transmission

MAINTENANCE

Transmission

Fluid

To ensure trouble-free operation

of

the gearbox, only use

Automatic Transmission Fluid (ATF). (Dexron

II

or

III).

Capacity

Add the fluid quantity for the proper model transmission to

the gearbox. After filling, check the fluid level with the dip-

stick. Adjust level as needed. Install the dipstick with the

sealing washer. operate unit, check fluid, check for leaks.

Transmission

Fluid

Quantity

HBW50

0.29

Quarts

(0

..

30

Liters)

HBW

100

0.33

Quarts

(0.35

Liters)

HBW

150

0.59

Quarts

(0.56

Liters)

HBW

150V

1.10

Quarts

(1.05

Liters)

HBW

250

1.84

Quarts

(1.75

Liters)

Fluid

Change

Change the fluid for the first time after about

50

hours

of

operation, then every

250

operating hours or at least once a

year or when you

change

engine

oiL

When changing the

fluid, also check the gearbox cooling device and clean or

replace

it

as necessary.

NOTE:

When changing the fluid. take care

flot

to lose the

drain plug sealing

H'Qsher.

The drain plug will leak without

rhis

sealing washel:

31

Checking

the

Bowden

Cable

or

Rod

Linkage

The Bowden cable or rod linkage should be checked at regu-

lar intervals. Check the neutral position

of

the operating lever

(on the control console) and the actuating lever (on the gear-

box). The minimum lever travel from the neutral position

to

the operating positions (0 - A = 0 - B) should be 35mm for

the outer and 30mm for the inner pivot point. Make certain

that

these minimum values arc safely reached. Check

the

cable or rod linkage for easy movahility and proper attach-

ment.

Propeller

Shaft

Alignment

The engine's transmission must be exactly aligned with the

propeller shaft. Misalignment will create excessive shaft and

bearing

wear

and can cause the transmission'5 rear seal

to

leak fluid.

The shaft/transmission coupling alignment should be checked

periodically and always when the boat

is

being recommis-

sioned after winter storage.

Lay-up/Winterize

If

the transmission

is

not used for periods

of

more than one

year,

it

should he completely filled with transmission fluid to

prevent corrosion.

Protect the input shaft and the output

flange

by

means

of

an

anticorrosive coating,

as

required.

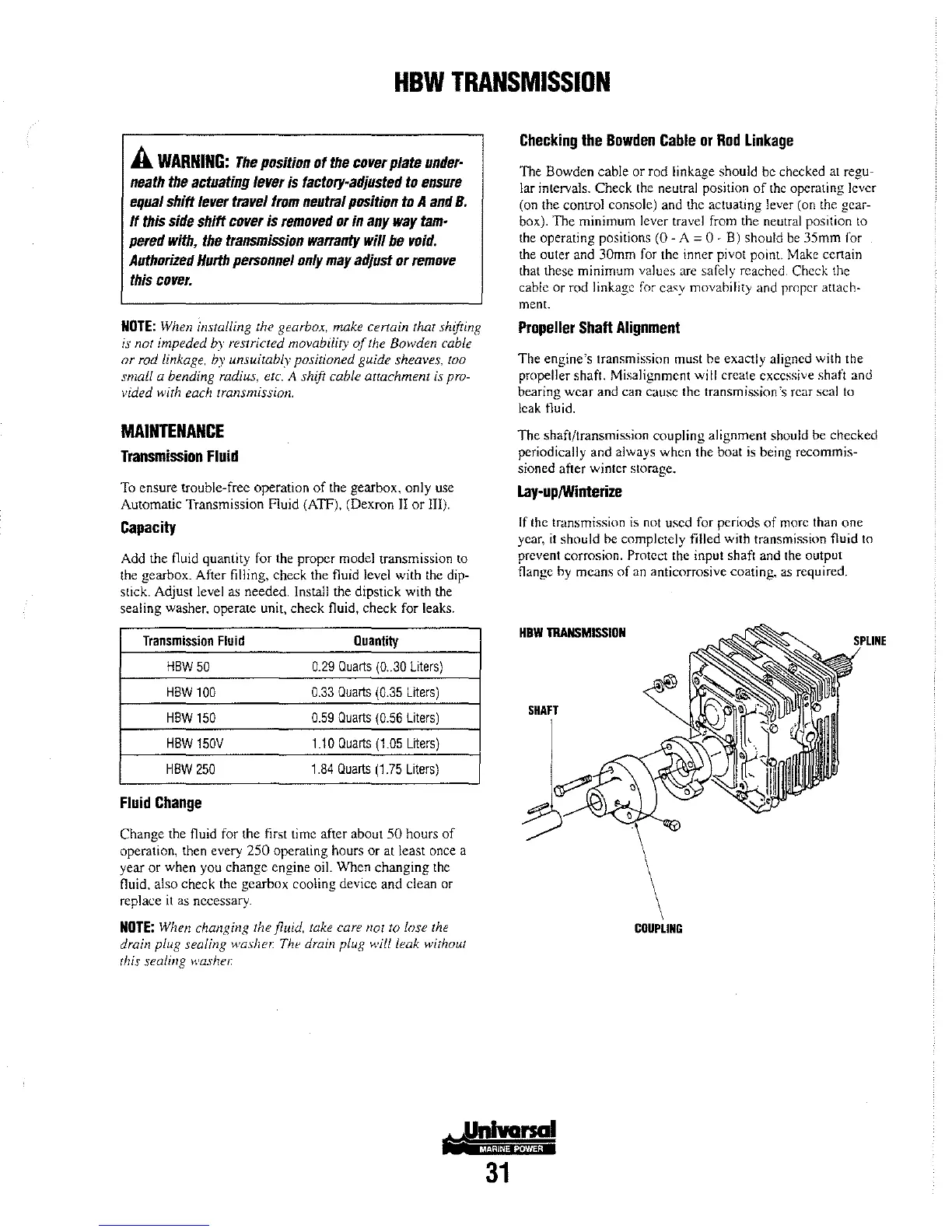

HBW

TRANSMISSION

SHAFT

COUPLING

Loading...

Loading...