19

The following procedure should be followed to clean and

8.

check the boiler ue passageways:

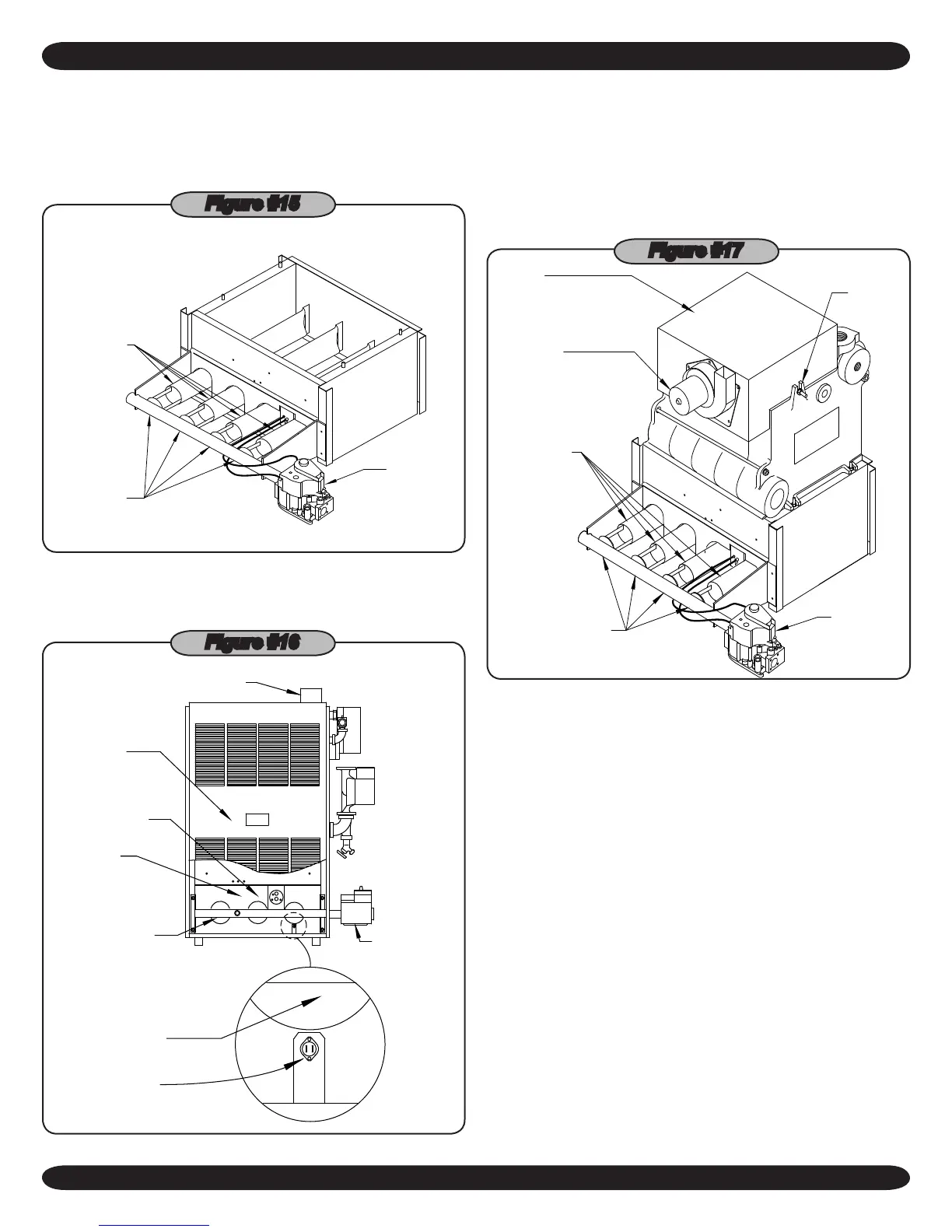

Remove the burners from the combustion chamber by A.

raising the burners up from the manifold orices and

pulling toward the front of the boiler. See

gure #15

.

Figure #15

Disconnect the vent pipe from the vent adapter.B.

Remove the top jacket panel. See C.

Figure #16

.

COMBUSTION

BURNER

(REMOVED)

BURNERS

GAS

VENT PIPE

CHAMBER

DOOR

VA LVE

ADAPTER

ROLL-OUT SAFETY

BURNER

SWITCH

JACKET

FRONT

PANEL

Figure #16

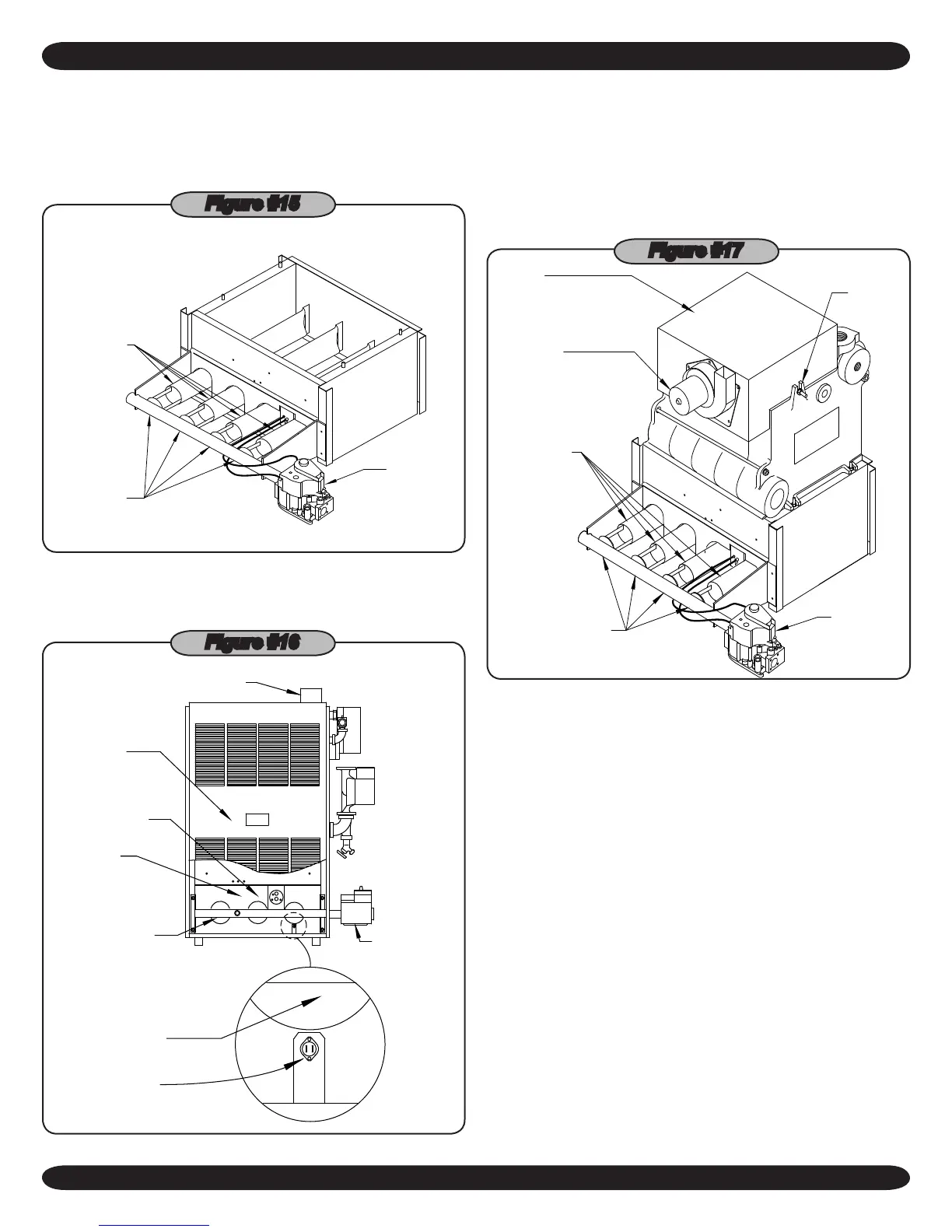

Disconnect the white compression tting from the pres-D.

sure switch.

Disconnect venter wires from relay.E.

Remove the ue collector and venter from the boiler F.

castings by loosening the hold-down bolts located on

each side of the collector. See

gure #17

.

BURNERS

ORIFICES

GAS VALVE

HOLD DOWN

BOLT

FLUE

COLLECTOR

VENTER

ASSEMBLY

A1795

Figure #17

Visually inspect the venter assembly for any unusual G.

wear or dirt build up. Clean with vacuum if necessary.

Place a sheet of heavy paper or similar material over H.

the bottom of the combustion chamber and brush down

the ue passageways. The soot and scale will collect

on the paper and is easily removed with the paper.

Vacuum out base and ueways and reassemble the I.

boiler in reverse order.

Seal ue collector and vent adapter with high tempera-J.

ture silicone. (+400°)

Start boiler to ensure proper operating condition.K.

Keep the area around the boiler clean and free of com-

9.

bustible materials such as gasoline, paints, paint thinner

and other such ammable vapors and liquids.

The free ow of combustion and ventilating air to the

10.

boiler and boiler room must not be restricted or blocked.

Some circulators require periodic servicing. These circula-

11.

tors usually have oil cups or openings at each end of

the motor and one for the shaft bearing. Put about one

teaspoon of SAE 20 or 30 non-detergent motor oil in each

GENERAL INSTRUCTION FOR SEASONAL START UP AND MAINTENANCE

Loading...

Loading...