20

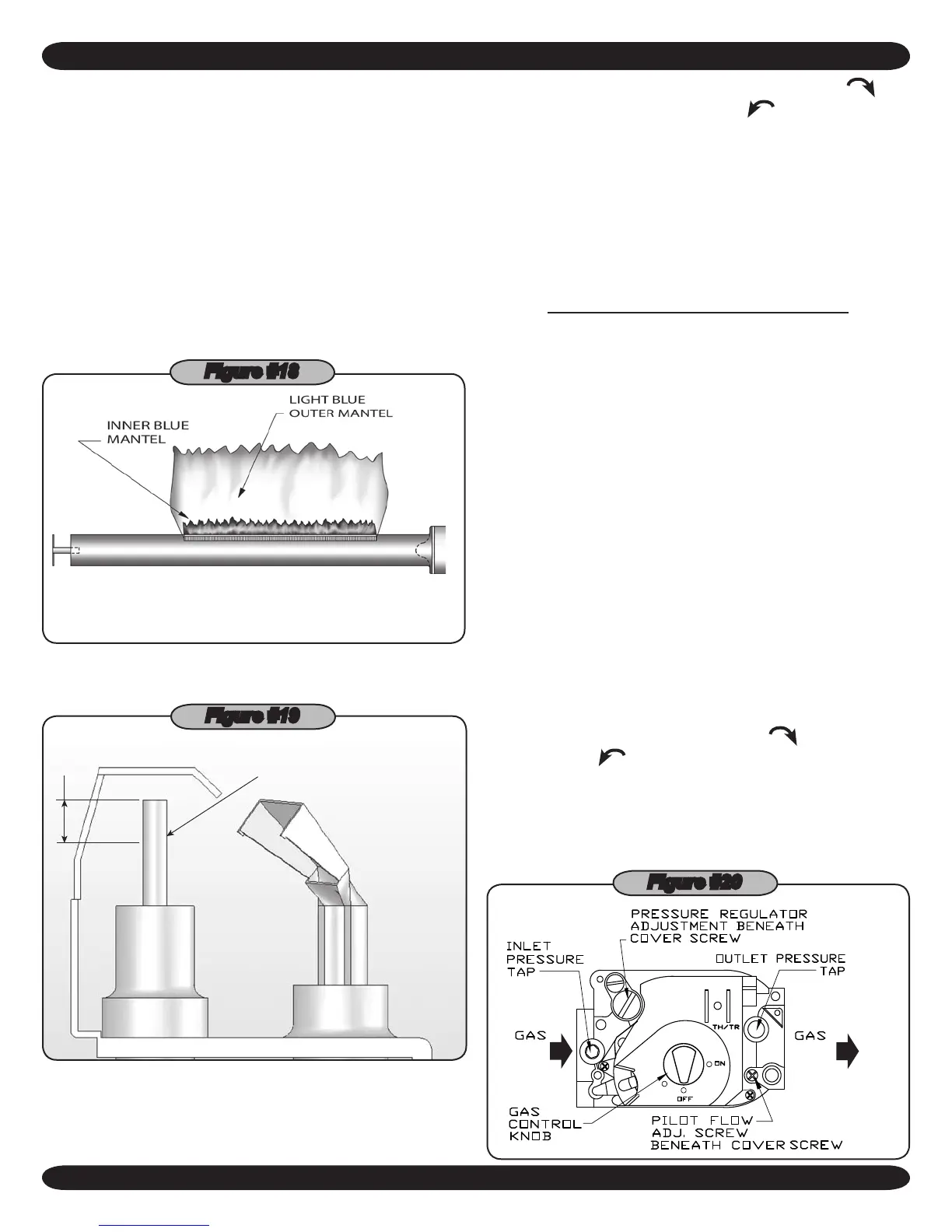

The main burner ame should form a

sharp blue inner mantel with no yellow.

opening twice per year. DO NOT OVER OIL. Follow the

manufacturers instructions attached to the circulator.

When oil cups or holes are not provided, bearings are

either permanently lubricated or water lubricated.

Visually check the main burners and pilot ame at the

12.

start of each heating season and again midway through

the season.

Check the burner throats and burner orices for lint and A.

dust obstructions. See

gure #17

.

The main burner ame should have a well dened in-B.

ner blue mantel with a lighter blue outer mantel. See

gure #18

.

Figure #18

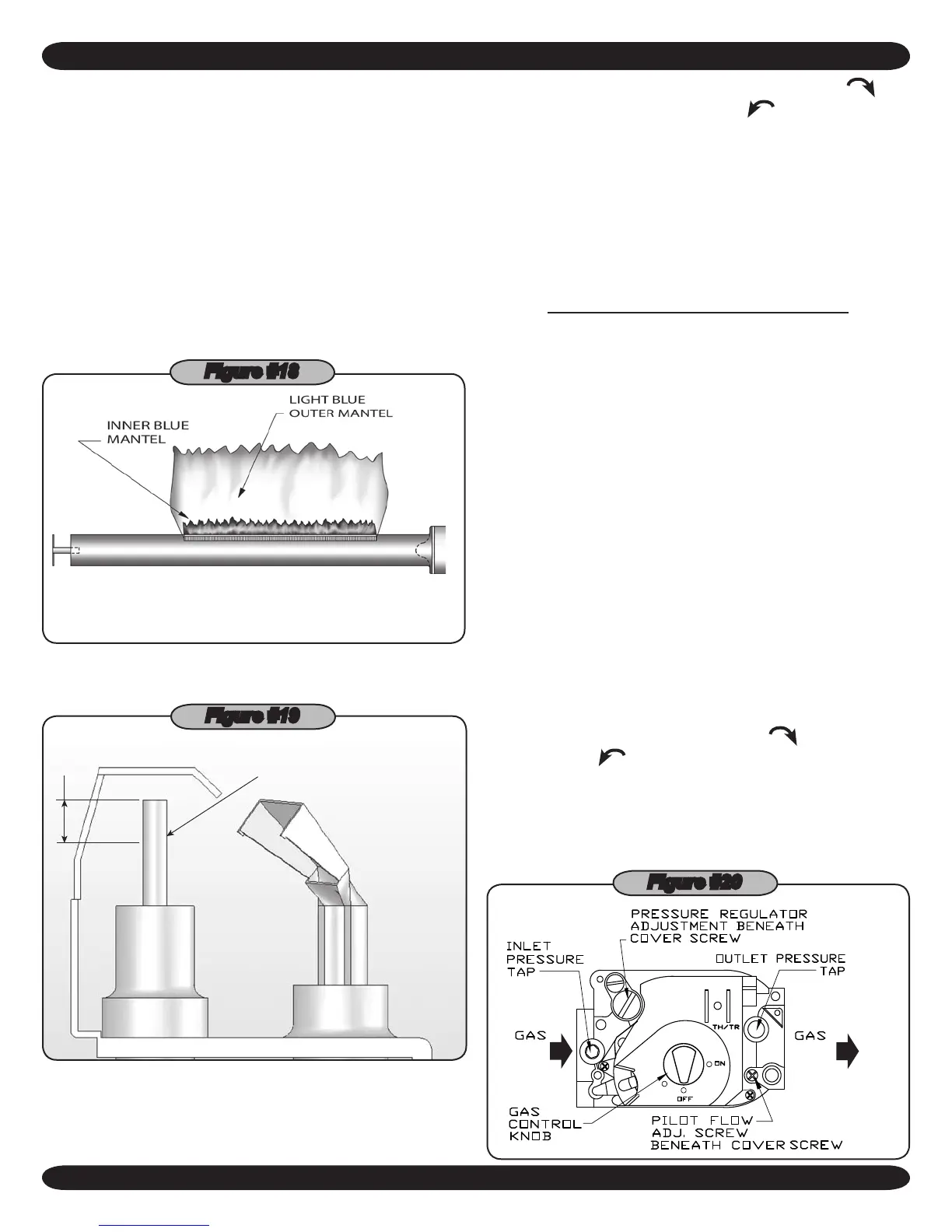

The pilot ame should envelop ⅜ to ½ inch of the tip of C.

the pilot sensing device. See

gure #19

.

IGNITION ELECTRODE

3/8” TO 1/2”

IN FLAME

Figure #19

Adjusting the pilot ame:

13.

Remove the pilot adjustment cover screw.A.

GENERAL INSTRUCTION FOR SEASONAL START UP AND MAINTENANCE

Turn inner screw (adjustment screw) clockwiseB. to

decrease and counterclockwise to increase the

pilot ame, see gure #20.

After adjustment, be sure to replace cover screw to C.

prevent possible gas leakage.

The main burners and the pilot burner should be D.

checked for signs of corrosion or scale build up.

Clean main burners and pilot burner with a steel bristle E.

brush.

CHECK GAS INPUT RATE TO BOILER

Maximum permissible gas supply pressure must not be

1.

higher and minimum supply pressure must not be lower

than what is specied on the rating plate.

To check for proper ow of natural gas to boiler using the

2.

gas meter, proceed as follows:

Turn off the gas supply to all other appliances, except A.

the boiler.

With the boiler operating, determine the ow of gas B.

through the meter for two minutes and multiply by 30 to

get the hourly rate (in cubic feet).

Divide the input rate shown on the rating plate by the C.

heating value of the gas as obtained from the local gas

company. This will determine the number of cubic feet

of gas required per hour.

If minor adjustment is necessary, adjust the pressure D.

regulator on the combination gas control. Increase or

decrease manifold pressure to obtain gas input required

as described on the rating plate. To increase, turn the

regulator adjusting screw clockwise

or counter-

clockwise

to decrease pressure, see Figure #20.

The manifold pressures are taken at the outlet side of

the gas valve.

Relight all the other appliances turned off in step "a." E.

above. Be sure all pilot burners are operating.

Figure #20

Loading...

Loading...