Do you have a question about the UTICA BOILERS SVB Series and is the answer not in the manual?

This document is the Installation, Operation & Maintenance Manual for the Utica Boilers SVB Series 3 Gas-Fired Hot Water Induced Draft Boilers.

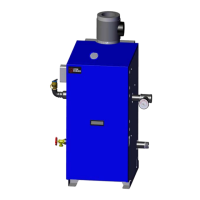

The Utica Boilers SVB Series 3 are gas-fired hot water induced draft boilers designed for residential and commercial heating applications. They are classified as Category I boilers, meaning they operate with a non-positive vent static pressure and with a vent gas temperature that may cause condensation in the vent. The boilers are equipped with an induced draft blower to assist in venting flue gases. They are designed to provide hot water for space heating and can be integrated into various heating systems, including those with zone control valves or refrigeration systems. The control module continuously monitors boiler water temperature and fires or shuts off the burner based on this data, aiming to satisfy the thermostat's call for heat efficiently. A feature is included to save energy by reducing boiler water temperature as the heating load decreases, with an override for external energy management systems or specific applications.

| Brand | UTICA BOILERS |

|---|---|

| Model | SVB Series |

| Category | Boiler |

| Language | English |

Loading...

Loading...