SVD48V series servo driver manual (PC software)

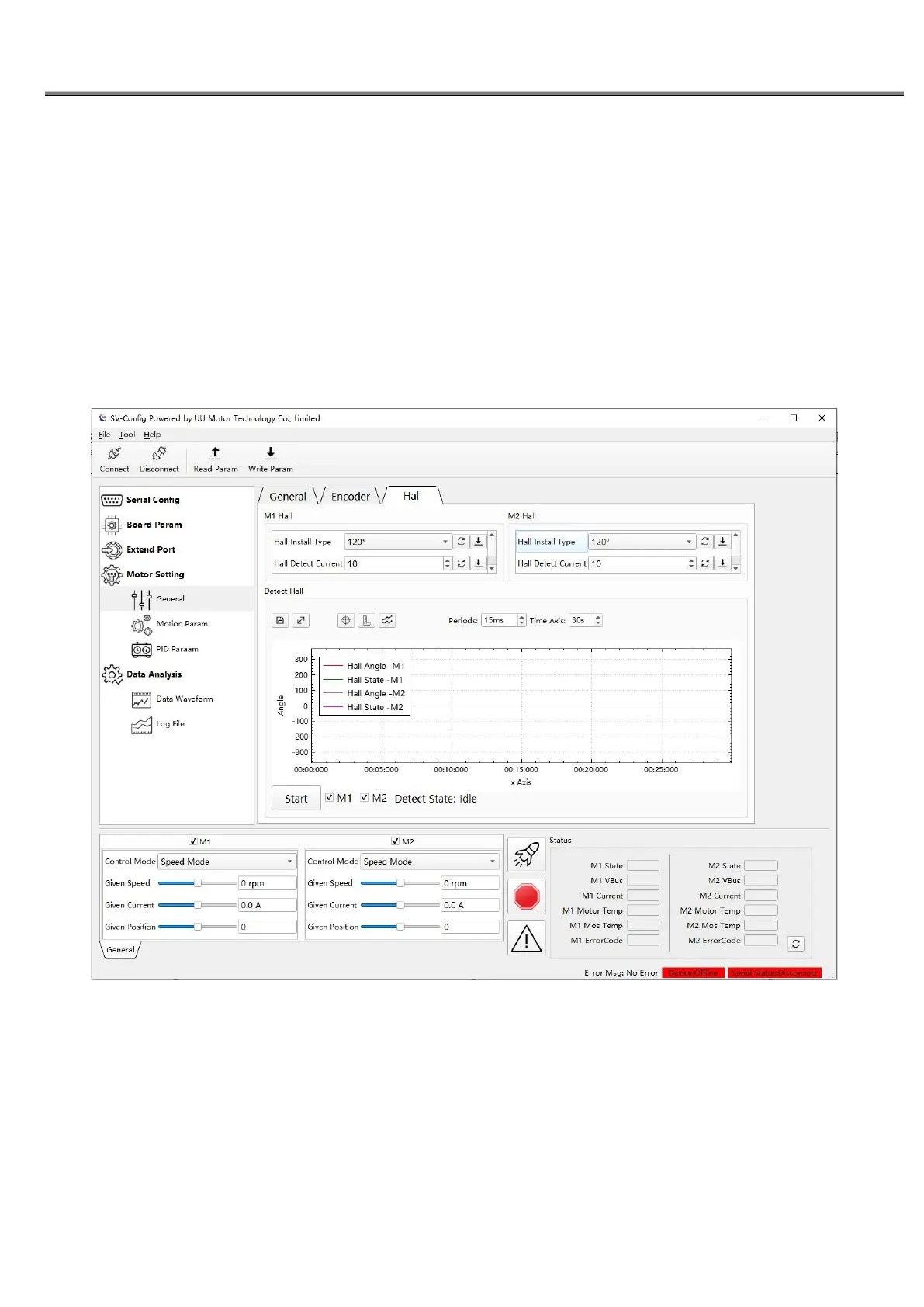

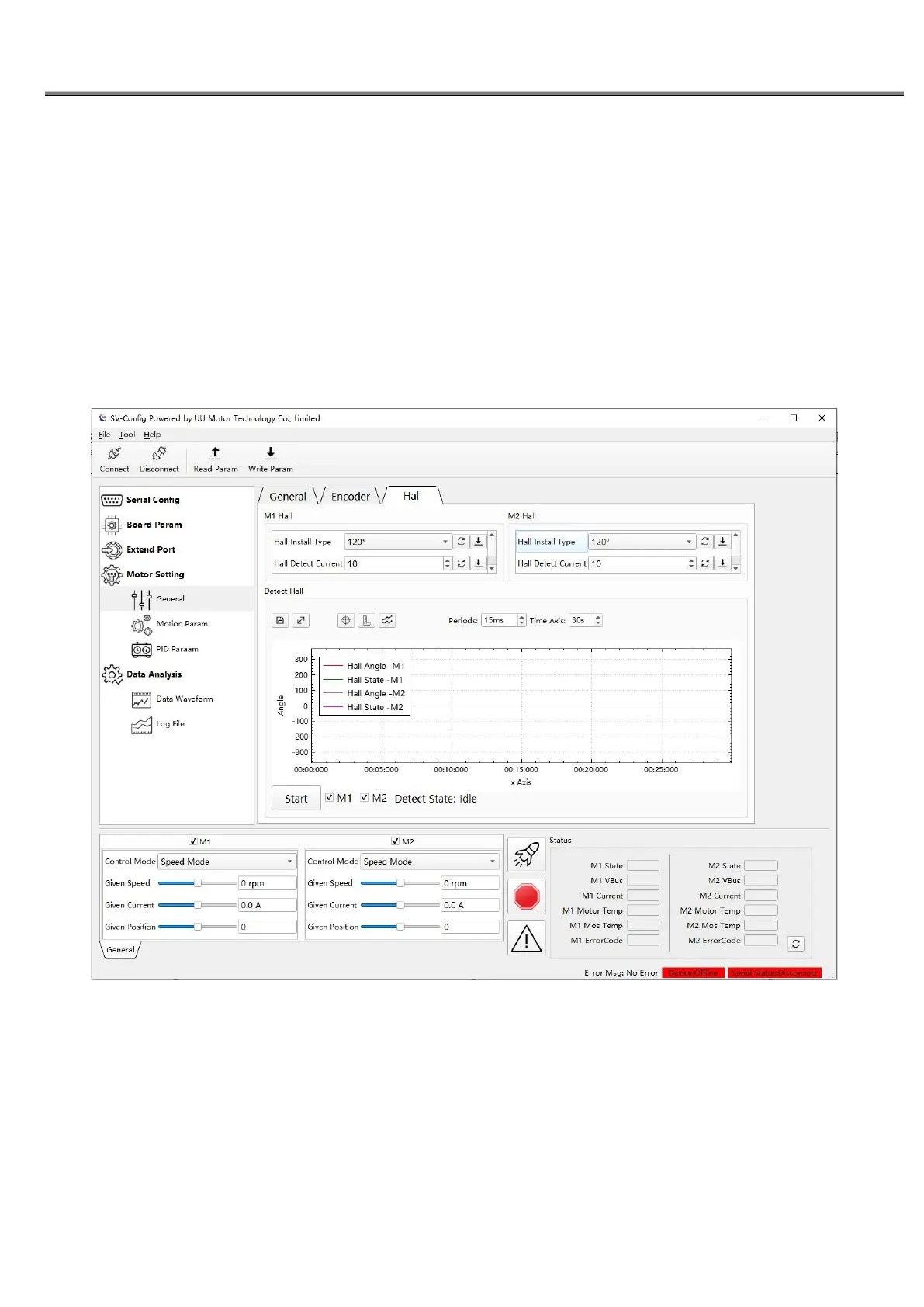

4.3.2.3. Motor Hall Sensor Parameters

There is a M1 and M2 tick option below, and the calibration will only be performed when the tick is on. Hall sensors

parameters are automatically saved after calibration.

Hall Sensor Calibration Process:

1. Calibration can only be performed after all parameters are set.

2.

Select the Hall mounting type.

3. Set the size of the calibration current, based on whether the motor rotates evenly.

4. Click the Start button and wait for the calibration to succeed.

Hall sensors need to be re-calibrated in the following situations:

1. Change the wire sequence of the three-phase wires of the motor.

2. Replace with new motor.

3. When the motor rotates in the opposite direction, modify the direction in the general parameters, write it to the

driver, and then re-calibrate.

Loading...

Loading...