VV

VV

V

aconacon

aconacon

acon Page 43

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

Vacon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

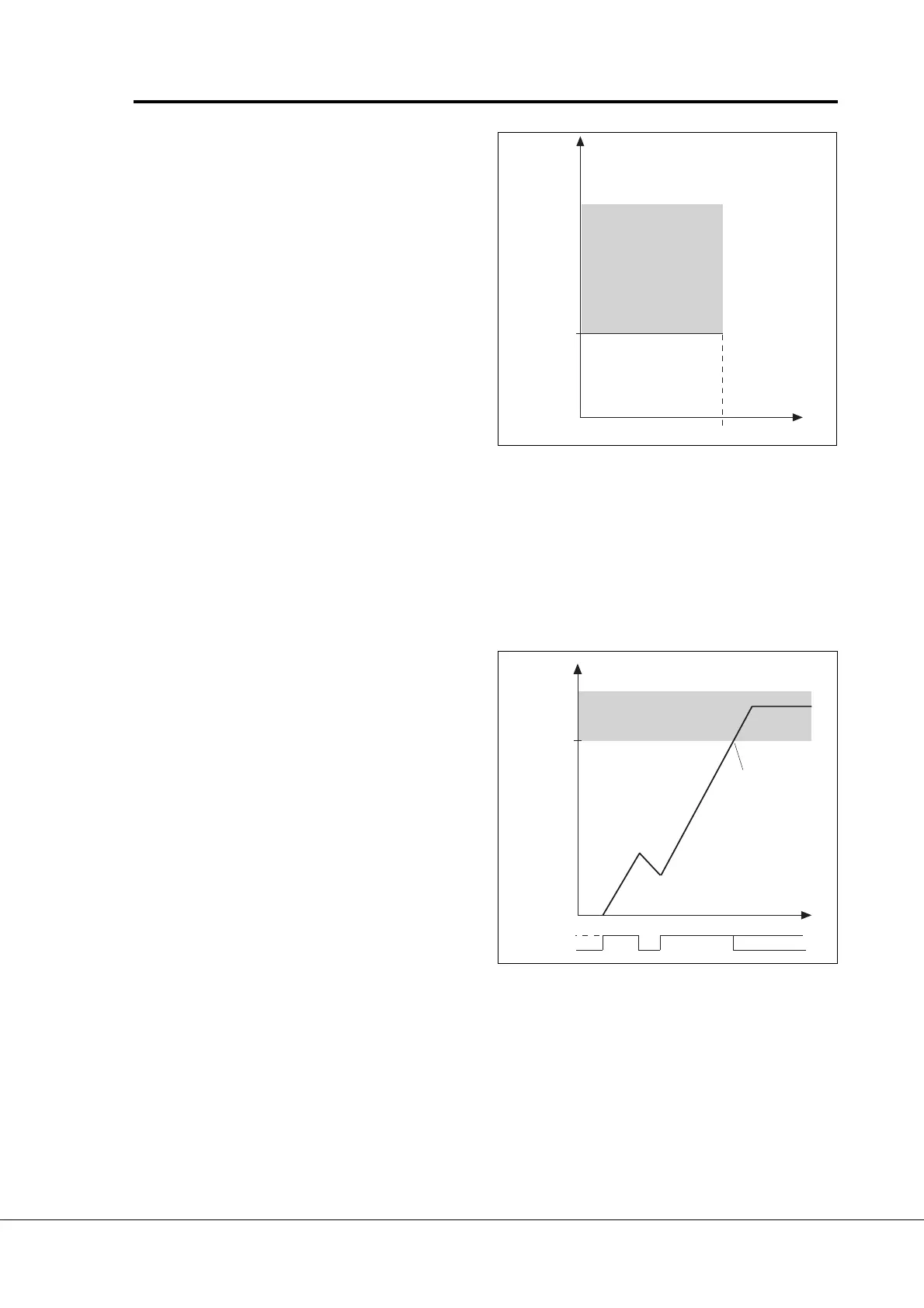

f

I

Par. 7. 11

Par. 7. 13

UMCH7_11

Stall area

Figure 6-28 Setting the stall

characteristics.

7. 127. 12

7. 127. 12

7. 12

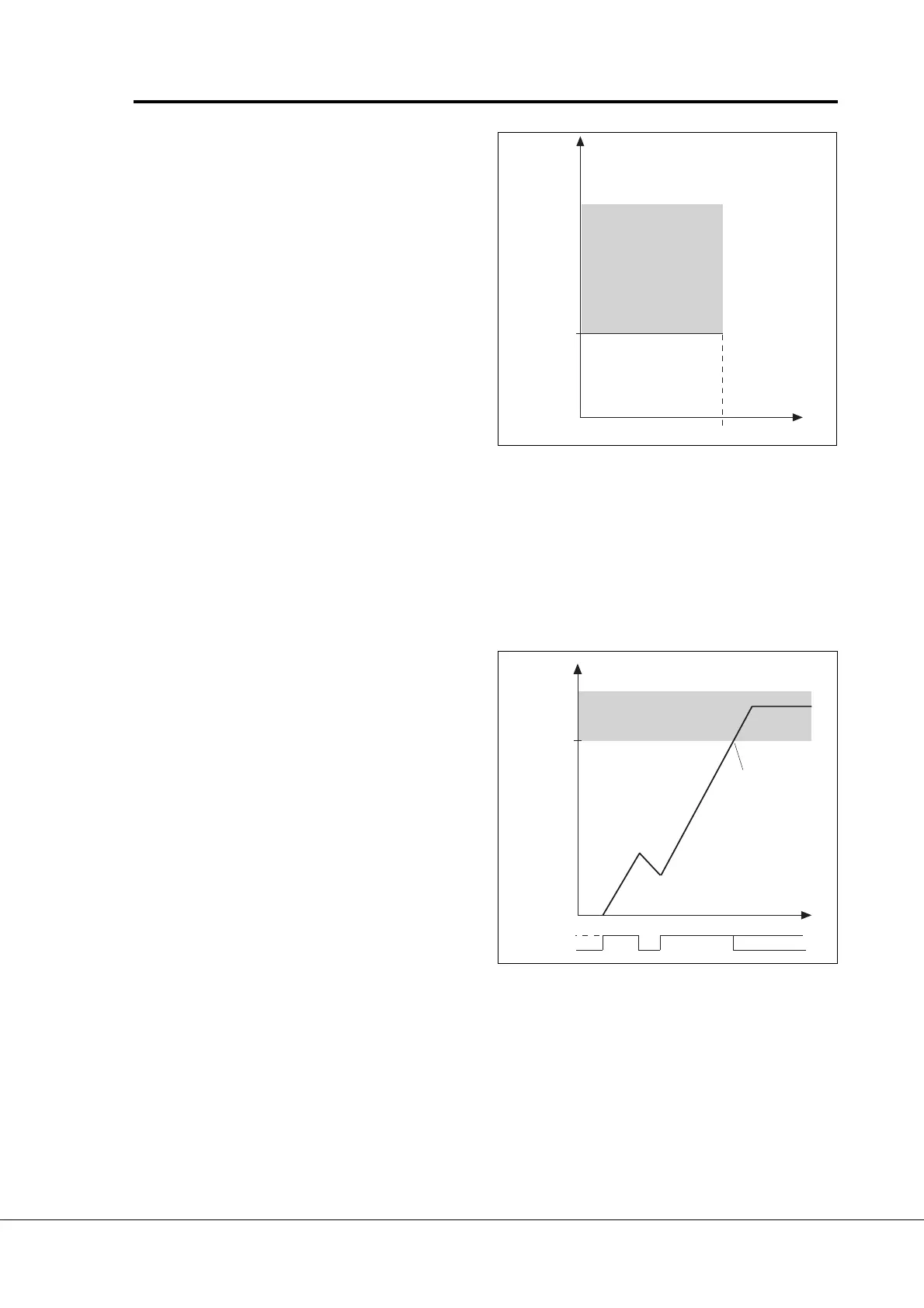

Stall timeStall time

Stall timeStall time

Stall time

The time can be set between 2.0—120 s.

This is the maximum allowed time for a stall stage. There is an internal up/down

counter to count the stall time. Refer to figure 6-29.

If the stall time counter value goes above this limit the protection will cause a trip

(refer to parameter 7

..

..

. 10).

Par. 7. 12

UMCH7_12

Trip area

Time

Stall time counter

Stall

No stall

Trip/warning

par. 7. 10

Parameters 7. 14— 7. 17, Underload protectionParameters 7. 14— 7. 17, Underload protection

Parameters 7. 14— 7. 17, Underload protectionParameters 7. 14— 7. 17, Underload protection

Parameters 7. 14— 7. 17, Underload protection

GeneralGeneral

GeneralGeneral

General

The purpose of motor underload protection is to ensure that there is load on the motor when the

drive is running. If the motor loses its load there might be a problem in the process, e.g. a broken

belt or dry pump.

Motor underload protection can be adjusted by

setting the underload curve with parameters

7

. .

. .

. 15 and 7

..

..

. 16. The underload curve is a squared

curve set between zero frequency and the field

weakening point. The protection is not active below

5Hz (the underload counter value is stopped). Refer

to figure 6-30.

7. 17. 1

7. 17. 1

7. 1

11

11

1

Stall current limitStall current limit

Stall current limitStall current limit

Stall current limit

The current can be set to 0.0—

200% x I

nMotor

.

In a stall stage the current has to

be above this limit. Refer to figure

6-28. The value is set as a

percentage of the motor's name

plate data, parameter 1

. .

. .

. 13,

motor's nominal current. If

parameter 1

..

..

.13 is adjusted, this

parameter is automatically

restored to the default value.

7. 137. 13

7. 137. 13

7. 13

Maximum stall frequencyMaximum stall frequency

Maximum stall frequencyMaximum stall frequency

Maximum stall frequency

The frequency can be set between

1—f

max

(par. 1

..

..

. 2).

In a stall state, the output

frequency has to be smaller than

this limit. Refer to figure 6-28.

Figure 6-29 Counting the stall time.

Loading...

Loading...