15

7) Close the unsealing valve (place the valve handle perpendicular to the valve).

8) Start degassing the chamber according to point 7. “Operating manual.” of this manual.

9) Control the amount of material accumulating in the cold trap.

10) If a large amount of material has accumulated inside the cold trap:

a. Close the cold trap valves: vacuum pump connecting valve and vacuum chamber connecting valve (place the valve

handles perpendicular to the valves).

b. Turn off the vacuum pump.

c. Open the unsealing valve (place the valve handle parallel to the valve). Allow the pressure inside the cold trap to

equilibrate with the ambient pressure.

d. Take out the inner tank using cold resistant gloves.

e. Remove any excess deposition material.

ATTENTION! The deposition material should be removed very carefully due to its very low temperature.

f. Place cleaned inner tank back into the outer tank.

g. Close the unsealing valve.

h. Open the vacuum pump connecting valve (place the valve handle parallel to the valve).

i. Start the vacuum pump. Lower the pressure inside the cold trap.

j. Open the vacuum chamber connecting valve (place the valve handle parallel to the valve).

k. Continue the degassing process.

l.

Clean the vacuum cold trap again if necessary (go back to point 10) a.).

11) When the degassing process is complete, close the vacuum chamber connecting valve and the vacuum pump connecting

valve (place the valves handles perpendicular to the valves).

12) Disconnect the vacuum pump and the vacuum chamber from the cold trap if needed.

13) Open the unsealing valve (place the valve handle parallel to the valve). Allow the pressure in the cold trap to equilibrate

with the ambient pressure.

14) Handle the remaining cooling agent following its safety instructions.

15) Clean the cold trap.

Be very careful when operating the cold trap. Especially when cleaning the cold trap from cold deposition

material.

The vacuum cold trap is very cold when the cooling agent is inside. Risk of frostbite in case of direct

contact with cold trap elements.

Use cold resistant gloves.

Do not touch the device if not necessary.

Always follow all cooling agent instructions and warnings.

The inner tank lid must not be pressed down by other objects nor have limited free lift.

A large amount of accumulated deposition material can block the airflow from the vacuum chamber to the vacuum pump. If

that happens, clean the vacuum cold trap according to point 10) of the instruction above.

Accumulated material, when reaches the ambient temperature and pressure, most often turns into liquid (e.g. water,

ethanol). When this happens, cleaning the cold trap is easier. Be very careful when cleaning cold trap before material turns into

liquid. The material is then very cold and there is a high risk of frostbite.

1) Place degassing material in the additional container into the chamber.

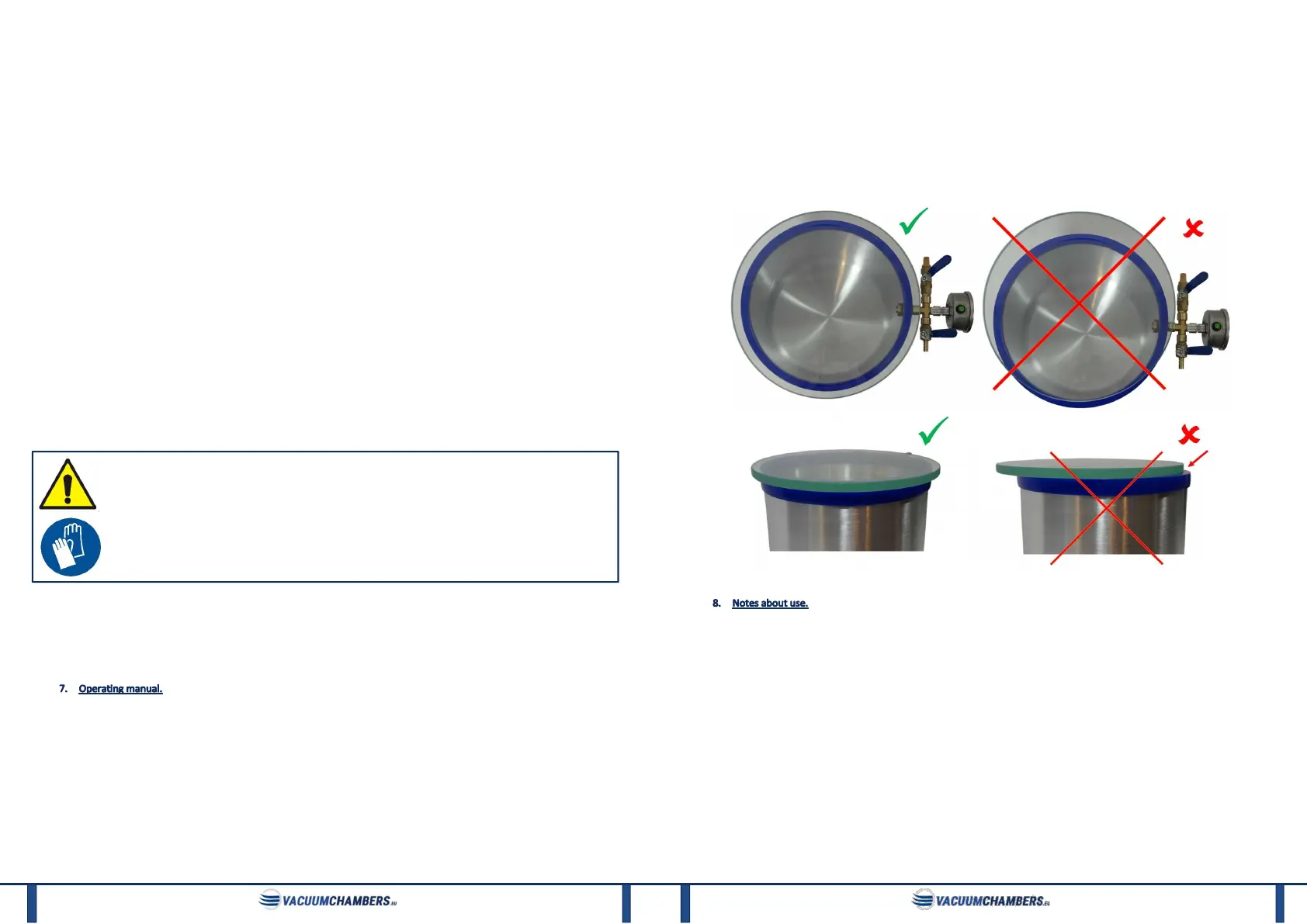

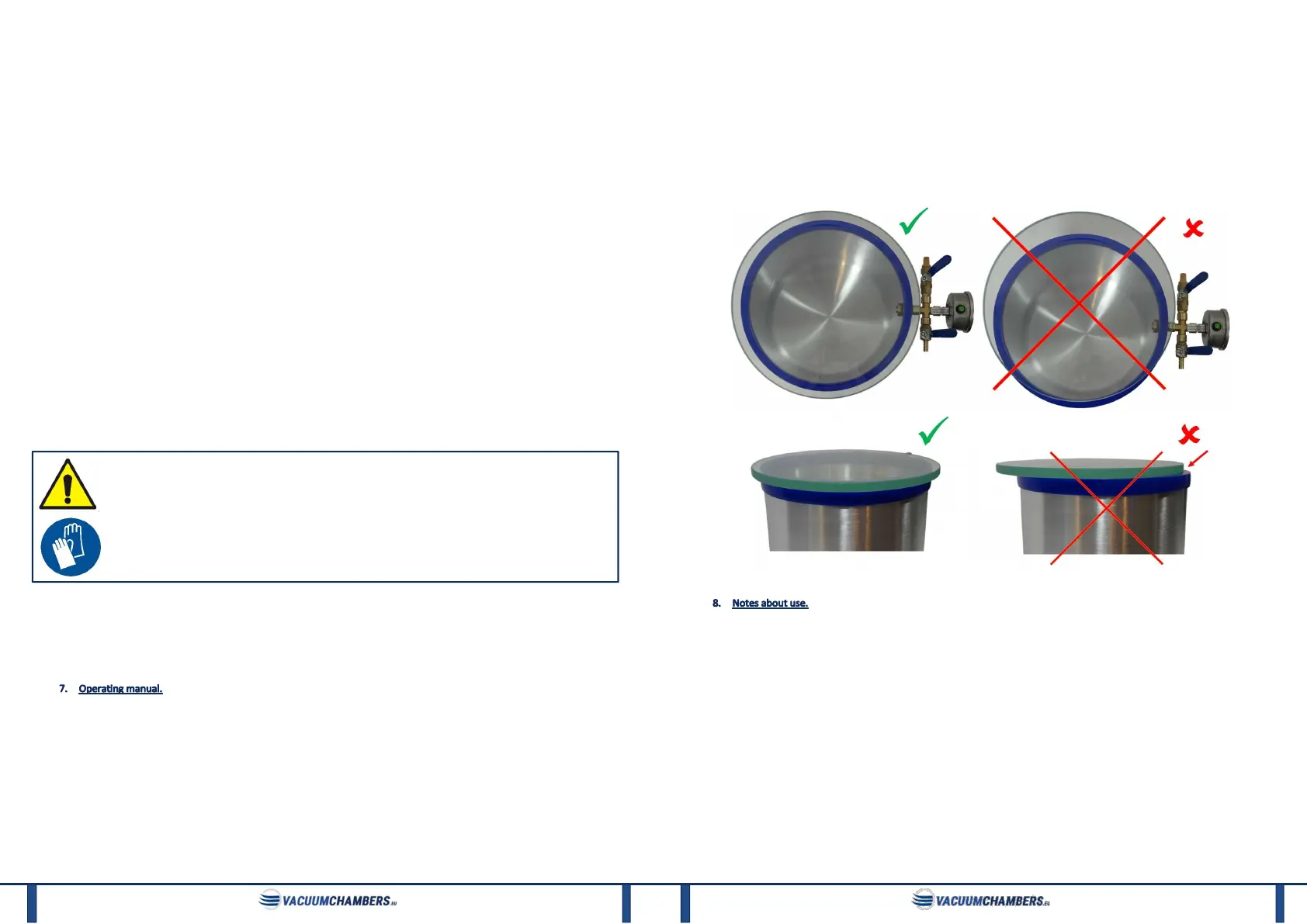

2) Place the lid on the chamber. Make sure it’s placed centrally on the tank - exactly as shown in photo 20 on the left.

The chamber must not be used if the lid is shifted to the side, as shown in photo 20 on the right. If the lid is in the wrong

position, it is necessary to correct lid position before starting to use the chamber.

For a metal lid with clamps (chamber with a stirrer mechanism), place the lid on the tank following paragraph "4C. Stirrer

mechanism.” of this manual.

3) Close the inlet air valve (set valve handle perpendicular to the valve).

4) Close the exhaust air valve (set valve handle parallel to the valve).

5) Turn on the vacuum pump.

6) In the first phase of the suction it may be necessary to press the lid down to the tank until the increasing vacuum in the

chamber is noticed.

16

7) During degassing, casting products significantly increase their volume, note that opening the inlet air valve prevents the

degassing products from spilling out when a too small container is used. The operator should control the process and react

according to the increase in volume of the product. So that the product does not get into the lid of the chamber and

contaminate the connections there.

8) Degassing should continue until the degassing material stops increasing its volume and rapidly drops and reduces its

volume. The material will have a homogeneous, clear appearance.

9) Before turning off the pump, close the exhaust air valve.

10) Turn off the vacuum pump.

11) Slowly open the inlet air valve to balance pressure inside a chamber. After this step, the lid can be removed.

12) The process above can be repeated for the filled forms to obtain the best results.

Photo 20: Correct (left) and incorrect (right) positioning of the lid on the chamber.

Proper work of the vacuum chamber can only be guaranteed by using a vacuum pump which allows achieving a vacuum of

at least 0.1mbar (10Pa). It is recommended to use vacuum pumps tested and recommended by VacuumChambers.eu.

Before starting work, make sure that the oil level in the pump is suitable. The pump can’t work without oil (possible pump

seizure) or with its excessive amount (possible oil splashing at the pump outlet).

In case of using the vacuum pumps without the protection against oil return (such as a one-way solenoid valve or

mechanical valve), disconnect the pump from the chamber after reaching the required vacuum. Remember to close the

exhaust air valve first. All VacuumChambers.eu pumps are equipped with a one-way valve.

When operating vacuum pumps that do not come from the VacuumChambers.eu offer, please refer to the operating

instructions supplied with the pump by the manufacturer.

Casting products placed in the chamber should be placed in an additional container that is large enough to avoid the spillage

inside of the chamber.

The vacuum gauge with removed green stopper plug shouldn’t be rotated downwards as it can cause glycerine leaking.

The chamber lid should only be taken off after the pressure in the chamber is equilibrated with the atmospheric pressure. In

the case of a very strong lid suction, waggle the lid from side to side, while gently holding the gasket with the other hand.

Raising the lid quickly can cause ripping off the gasket. Especially in the case of new silicone gaskets, there may be an

Loading...

Loading...