12

3 General requirements

Instructions for installation and servicing ecoMAX12

3.5 Boiler location

The location chosen for the boiler must permit the provi-

sion of a satisfactory flue termination. The location must

also provide adequate space for servicing and air circu-

lation around the boiler. The boiler may be installed in

any room, although particular attention is drawn to the

requirements of BS7671 (IEE Regulations), the electrical

provisions of the Building Standards (Scotland)

Regula–tions, and in IE the current edition of IS813 and

the current ETCI rules, in respect of the installation of a

boiler in a room containing a bath or shower.

Note:

Where a room sealed boiler is installed in a room

containing a bath or shower, any electrical

switch or boiler control utilising mains electricity

should be so situated that it cannot be touched

by a person using the bath or shower.

Where the installation of the boiler will be in an unusual

location, special procedures may be necessary and BS

5546 and BS 6798 give detailed guidance on this aspect.

The boiler must be mounted on a flat, vertical wall, which

must be sufficiently robust to take the weight of the boi-

ler. The boiler may be installed on a combustible wall,

subject to the requirements of the Local Authorities and

Building Regulations.

A compartment used to enclose the boiler must be desi-

gned and constructed specifically for this purpose. (An

existing cupboard or compartment may be used provi-

ded that it is modified for the purpose). Details of essen-

tial features of cupboard/compartment design including

airing cupboard installations are given in BS 6798. If the

boiler is to be fitted in a timber framed building, it should

be fitted in accordance with Institute of Gas Engineers

Publication IGE/UP/7/1998 ”Guide for Gas Installation in

Timber Framed Housing”.

3.6 Gas supply

The gas supplier should ensure the availability of an

ade–quate supply of gas. A gas meter may only be

connected to the service pipe by the supplier of gas or

their contrac–tor. An existing meter should be checked to

ensure that it is capable of passing the rate of gas supp-

ly required.

Installation pipes should be fitted in accordance with

BS 6891. In IE the current edition of IS 813. Pipework

from the meter to the boiler must be of an adequate

size. Do not use pipes of a smaller size than the boiler

gas connection (15 mm). The complete installation must

be tested for soundness and purged as described in

BS 6891.

3.7 Flue system

3.7.1 Standard 100mm flue system

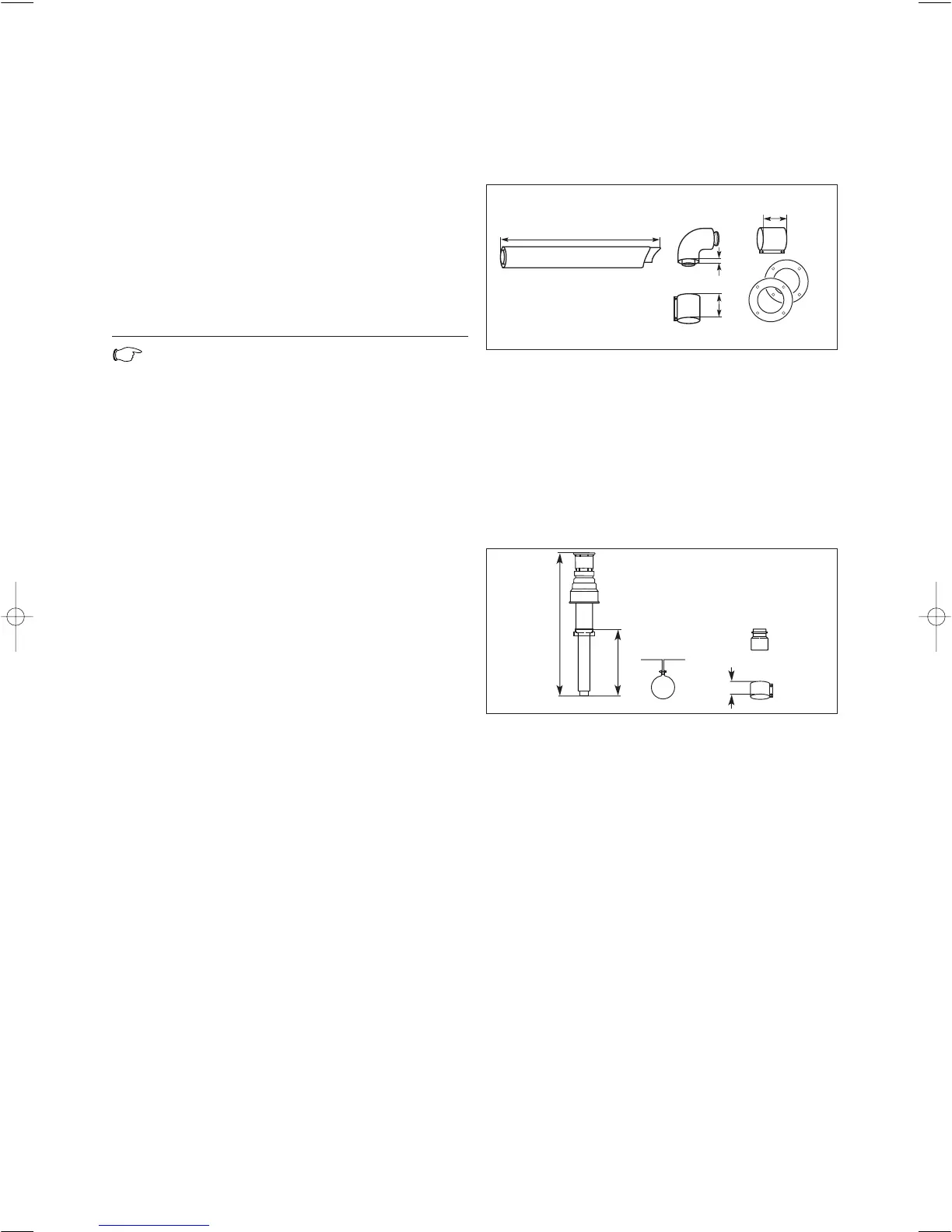

Fig. 3.3 Art.–No. 303 930

The standard 100 mm flue system (Art. No. 303 930) is

suitable for installations up to 740 mm measured from

the centre of the boiler flue outlet to the outside face of

the wall.

Flue extensions are available to extend this length up to

8 m for ecoMAX 828/2, 613/2, 618/2 and 622/2, 7 m for

ecoMAX 824/2 and 4 m for ecoMAX 635, 835. Both 90°

bends and 45° elbows are also available to increase sit-

ing flexibility.

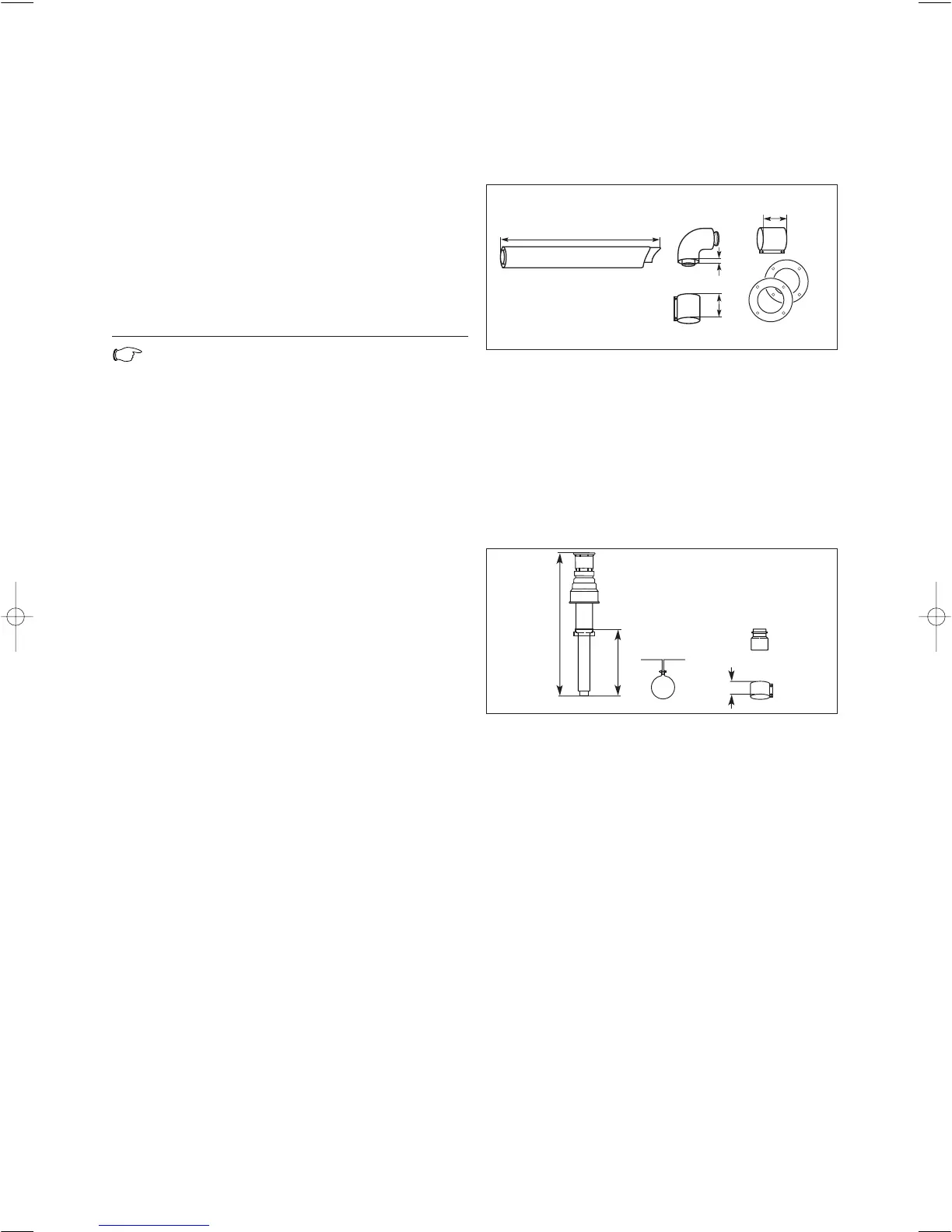

Fig. 3.4 Art.–No. 303 900

3.7.2 Optional 125 mm flue system

A concentric flue system of 125 mm outside diameter is

available and can be used to achieve flue lengths up to

13 m for ecoMAX 613/2, 25 m for ecoMAX 618/2, 824/2,

30 m for ecoMAX 622/2 and 828/2 and 21 m for ecoMAX

635, 835. A vertical flue system is also available. Refer

to flue system installation instructions for full details.

Loading...

Loading...