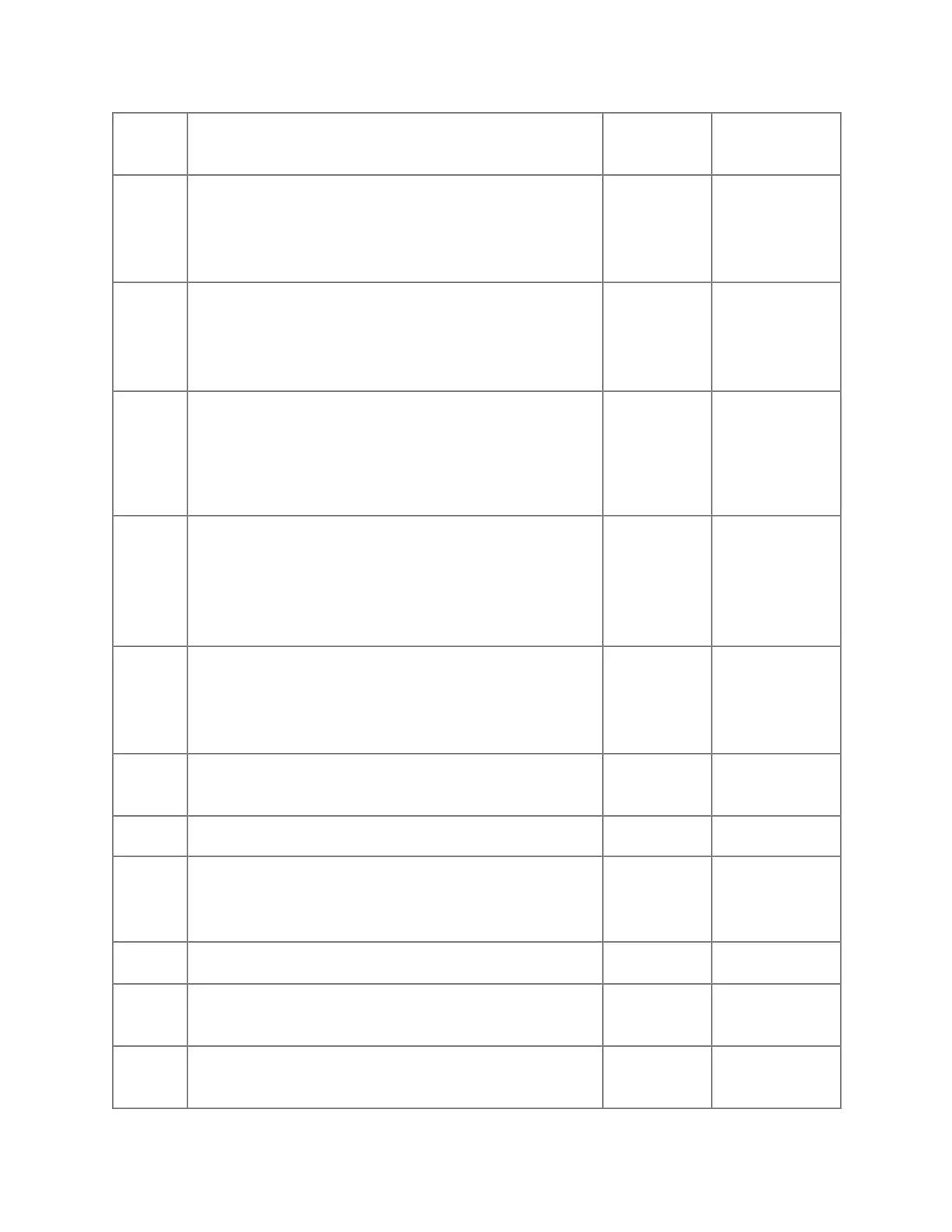

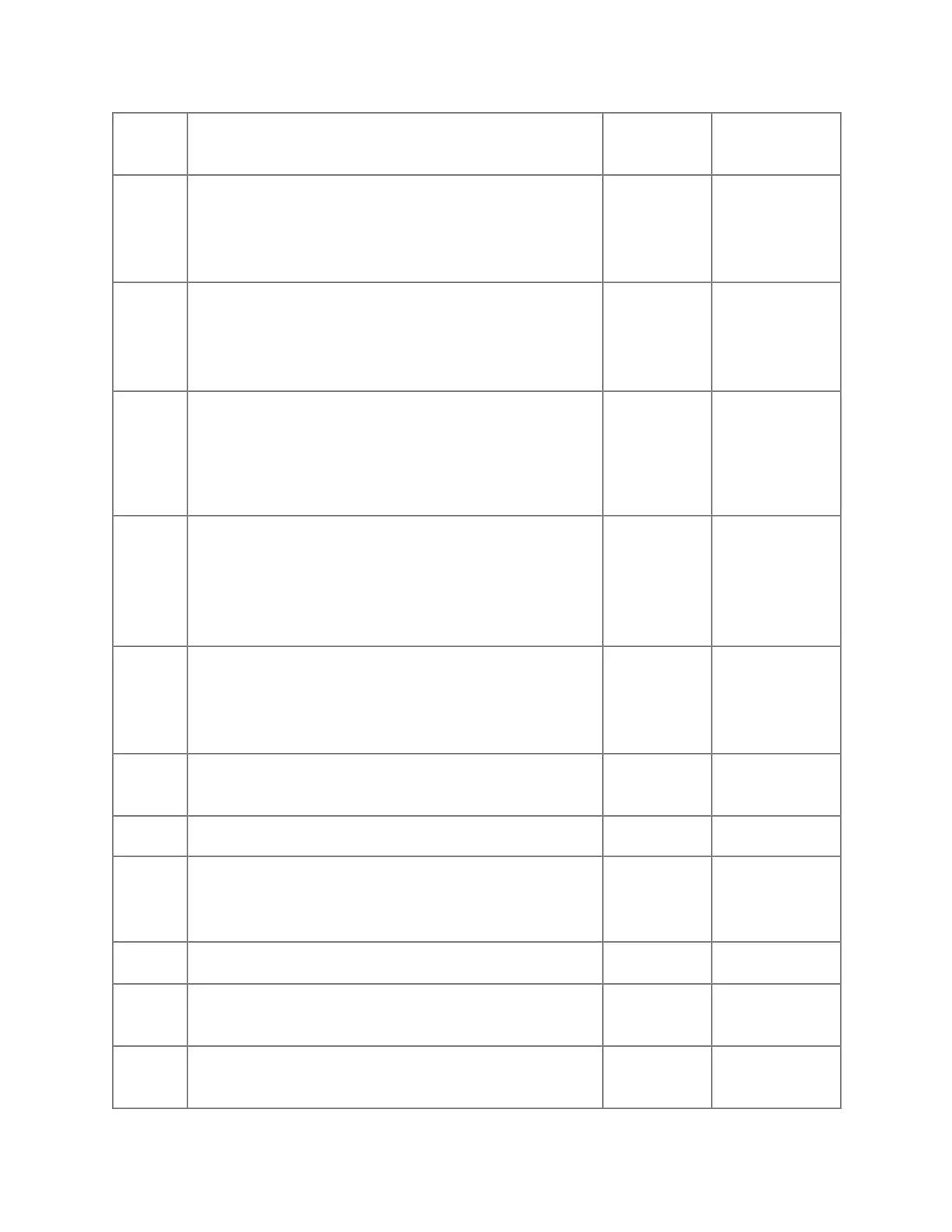

Carry out a general inspection of the boiler for dirt

and dust and clean as necessary.

Visually inspect the complete heat engine for its

general condition and for signs of corrosion, sooting

or other forms of damage. If damage is evident

proceed to column 2.

Measure the gas flow rate during operation with

maximum load (Kap. 5.9.2). If the gas flow rate

complies to the Table 5.1 continue with column 1, if

not proceed to column 2.

Check the gas inlet working pressure (Kap. 5.9.3)

operation with maximum load. If the gas inlet

working pressure complies to the Table 5.2 continue

with column 1, if not proceed to column 2.

Check combustion by measuring CO, CO2and

CO/CO2. If the values are outside the tole rances of

Table 7.1 proceed to maintenance column 2. You

must not proceed with the maintenance if a new

burner door seal kit is not available.

Isolate the boiler from the power mains. Check

whether the electrical plug connections and the

other electrical connections are fitted tightly and

correct them if necessary.

Close the gas isolator cock and the service valves.

Remove the compact thermal module.

Check the integrity of all combustion circuit seals,

especially the burner door seal. If there are any

damages repair them before proceeding.

Clean the heat exchanger.

Check whether the burner is dirty and clean it if

necessary.

Check the condensate siphon in the boiler, clean

and fill if necessary.

Loading...

Loading...