62 Installation and maintenance instructions 0020244997_07

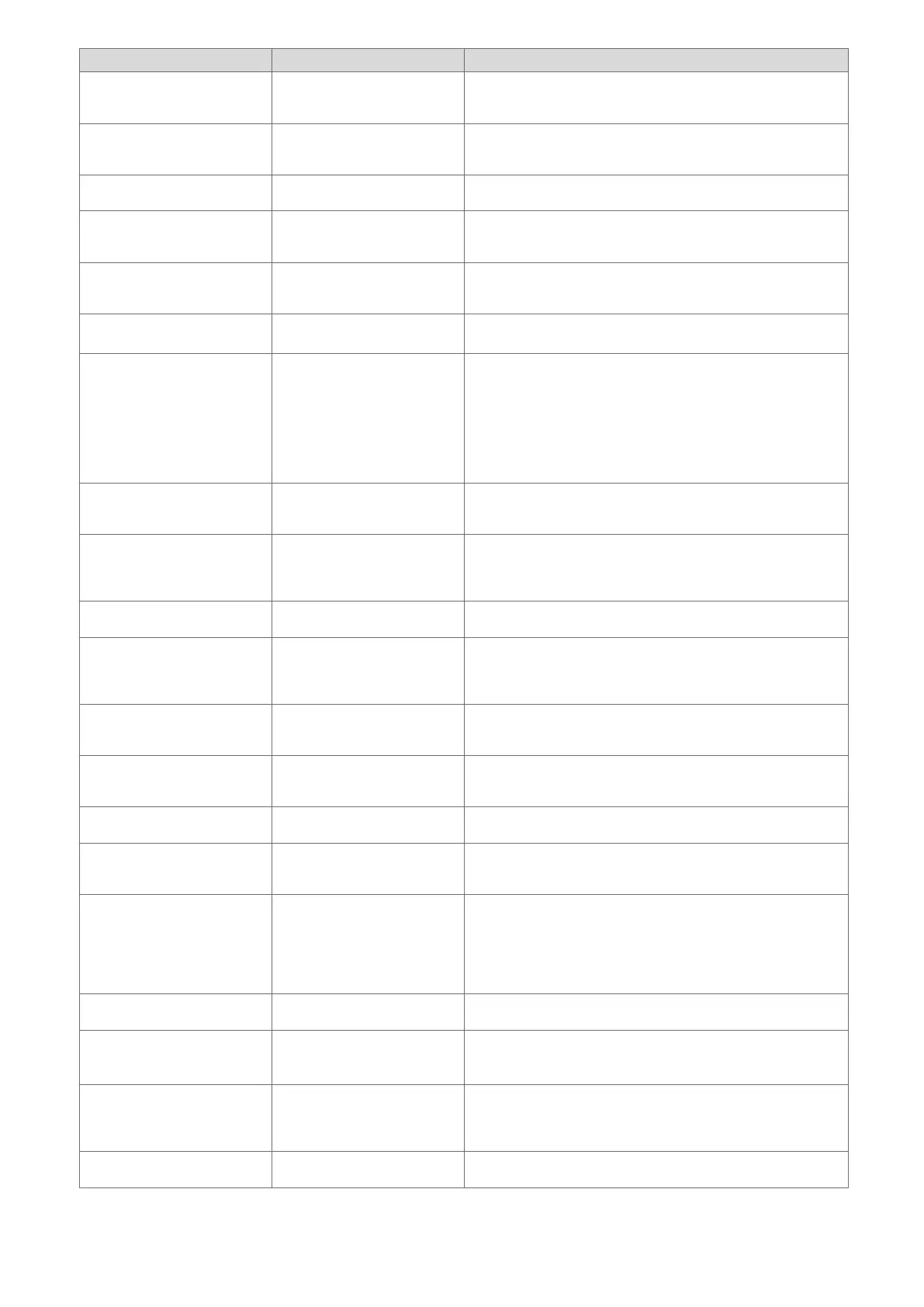

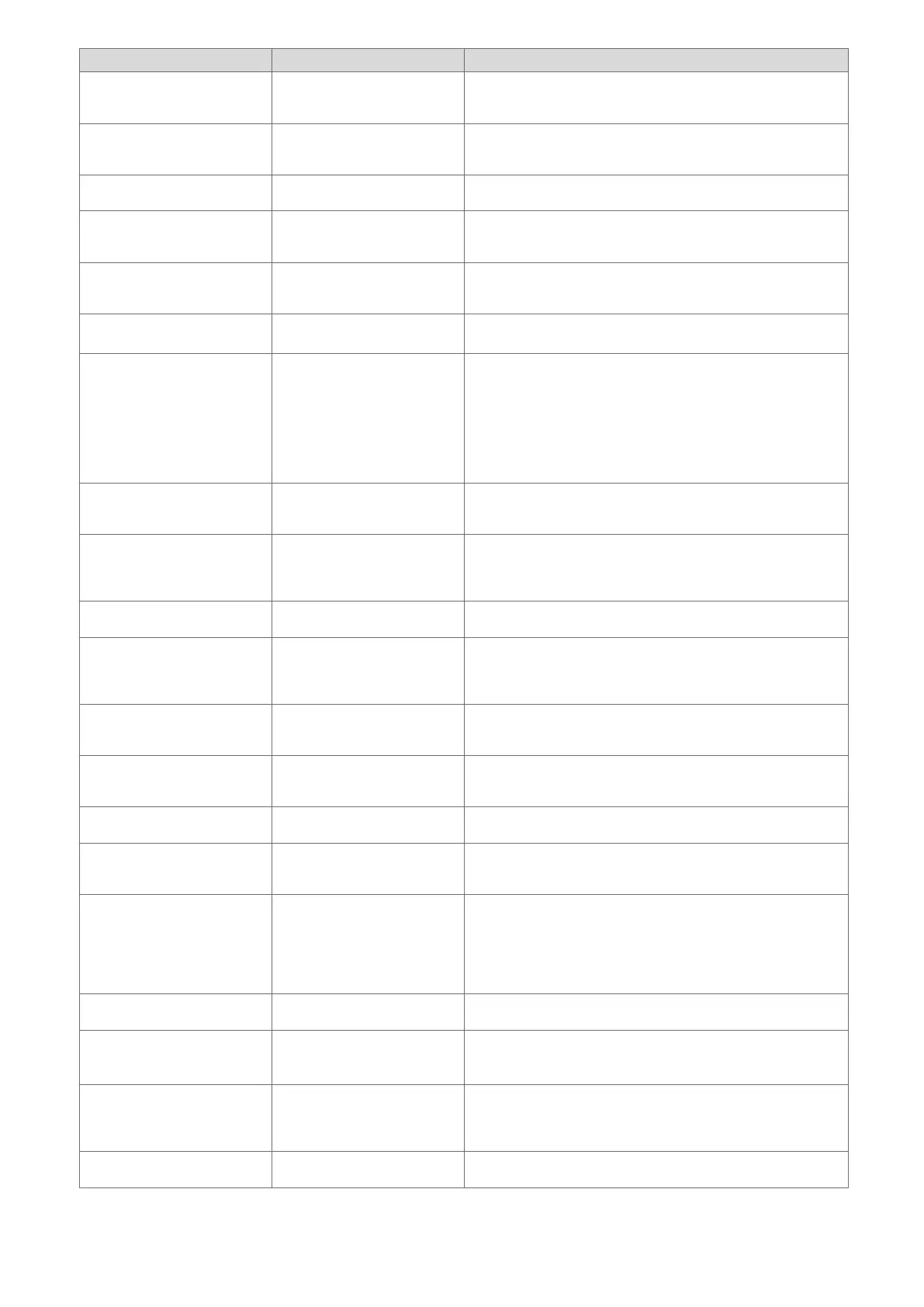

Code/meaning Possible cause Measure

F.68 Fault: Flame signal un-

stable

Flame monitor reports an un-

stable flame signal

▶ Check: Air ratio, gas flow pressure, condensate route (block-

age), gas injector, ionisation flow (cable, electrode), flue gas

recirculation.

F.70 Fault: Invalid Device Spe-

cific Number

Incorrect/missing Device

Specific Number or

incorrect/missing coding resistor

▶ If the display and PCB have been replaced, change the Device

Specific Number under D.93.

F.71 Fault: Flow temperature

sensor

Flow temperature sensor re-

turns implausible values

▶ Check: Flow temperature sensor (correct thermal connection).

F.72 Fault: Flow/return temper-

ature sensor

Temperature difference

between flow and return

temperature sensor is too great

▶ Check: Flow temperature sensor/return temperature sensor

(function, correct thermal connection).

F.73 Fault: Water press. sensor

(signal too weak)

Water pressure sensor reports

that the water pressure is too

low

▶ Check: Water pressure, earth connection, cable, plug, water

pressure sensor (short circuit to GDN).

F.74 Fault: Water press. sensor

(signal too strong)

Water pressure too high 1. Drain water.

2. Check the water pressure sensor.

F.75 Fault: Pump/ water short-

age

Insufficient pressure jump de-

tected when starting the pump

1. Check: Water pressure sensor, heating pump (blockage),

heating circuit (air, sufficient water volume), adjustable by-

pass, external expansion vessel (must be connected at the

return). Activate check programme P.0.

2. If a low loss header or heating pipes with a diameter greater

than 1 1/2 inch are installed, replace the 3/4-inch seal in

the heating flow with a screen. If required, install the F.75

service set.

F.77 Fault: Flue non-ret.

valve/condens. pump

No flue non-return flap feed-

back; condensate pump over-

flow

▶ Check: Cable to VR40 accessory, flue non-return flap (wiring,

feedback switch), condensate pump, bridge from the surface-

mounted thermostat, 2 in 7 multi-functional module (bridge).

F.78 Interruption: DHW outlet

sensor at ext. control

UK link box is connected

without the domestic hot water

temperature sensor being

bridged

1. Check: Accessory (configuration/electrical connection).

2. The unit displays a fault, but the unit has not malfunctioned.

F.80 Fault: actoSTOR inlet

sensor

Inlet temperature sensor defect-

ive or not connected

▶ Check (only in conjunction with F.91): NTC sensor, plug, cable

harness, PCB.

F.81 Fault: cylinder charging

pump

Cylinder is not fully charged

after specified time

▶ Check (only in conjunction with F.91): Cylinder charging

sensor, cylinder sensor, impeller sensor/limiter, prioritising

diverter valve, pump, actoSTOR pump (air), cable harness,

secondary heat exchanger (blockage).

F.82 Fault: Ext. current anode External current anode defect-

ive or not connected

▶ Check: Cable harness, external current anode. If the external

current anode is not installed: Plug edge connector X43 with a

bridge into the PCB.

F.83 Fault: NTC temp. gradient Temperature difference

between flow and return

temperature sensor is too small

▶ Check: Flow/return temperature sensor (function, correct

thermal connection), sufficient water volume.

F.84 Fault: NTC temp. diff. im-

plausible

Temperature difference is im-

plausible

▶ Check: Flow/return temperature sensor (correct thermal con-

nection, sensors are inverted).

F.85 Fault: NTCs fitted incor-

rectly

Flow/return temperat-

ure sensors returning

incorrect/implausible values

▶

Check: Flow/return temperature sensor (correct thermal con-

nection).

F.90 Fault: Communication Communication with actoSTOR

interrupted

1. Check: Plug, check cable harness to the actoSTOR module

(PEBus).

2. If the product is to be operated without an actoSTOR:

Set D.092=0, if required, plug edge connector X31 into

the BMU, if required plug edge connector X1 into the

actoSTOR.

F.91 Fault: actoSTOR sensor Sensor on the actoSTOR is

defective

▶ Check: Plug, cable harness, sensor.

F.92 Fault: Incorrect gas type The coding resistor on the PCB

does not match the gas group

that is entered

1. Check: Coding resistor.

2. Carry out the gas family check again and enter the correct

gas group.

F.93 Fault: Check gas route Combustion quality outside the

permitted range

▶ Check: Gas injector (suitable for the gas group), flue gas re-

circulation, gas group, internal pressure measuring point in the

Venturi (blockage). Do not use any lubricants on the O-ring in

the Venturi.

F.94 Fault: Vortex and differen-

tial pressure

Sensors return implausible val-

ues.

▶ Check: Cable harness, plug, sensors.

Loading...

Loading...