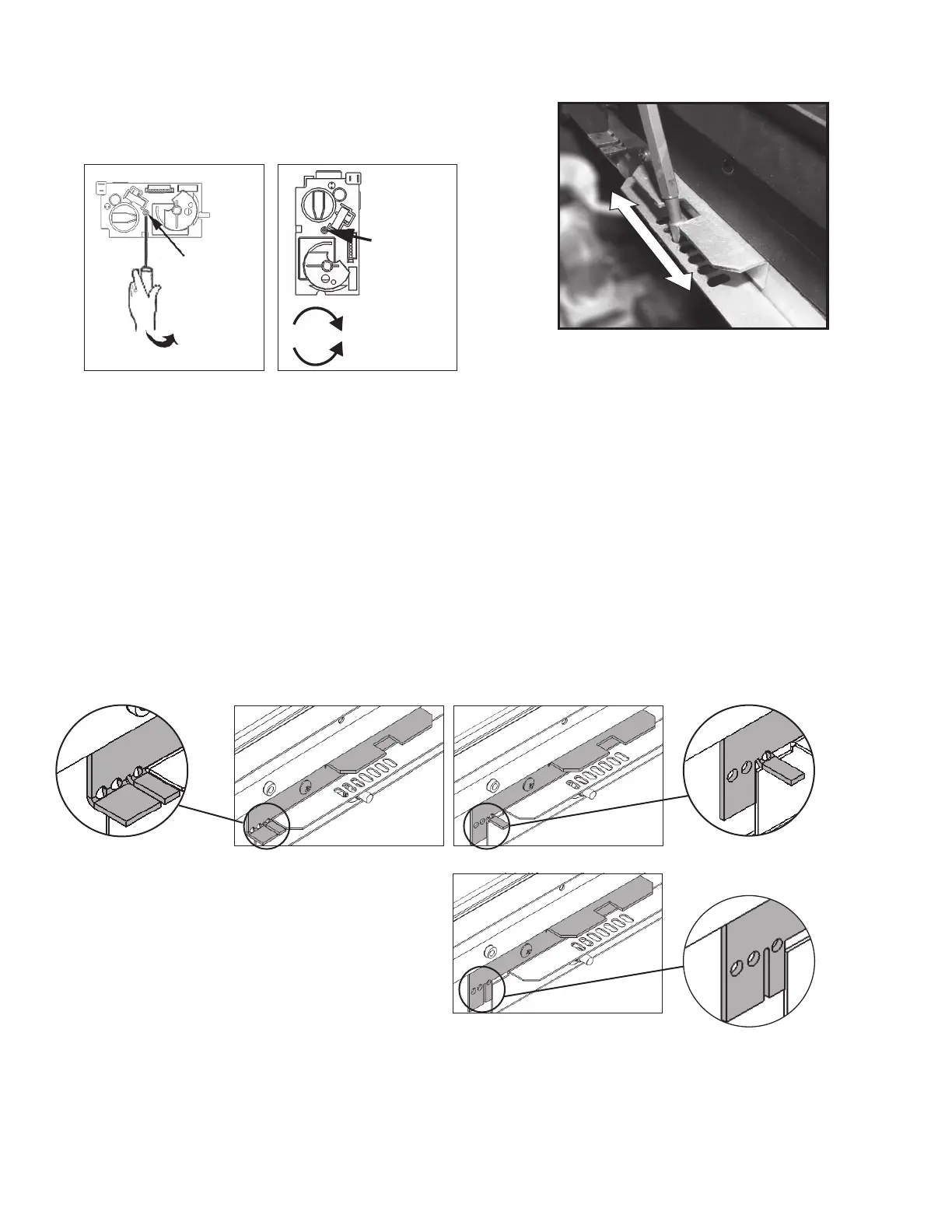

4. Adjust the pressure adjustment screw using a small

jeweller’s size fl at blade screwdriver—as shown

below—while the appliance is running at full input

to produce the manifold pressure, as per

Specifi cations table on page 1.

5. Check all the fi ttings for leaks.

6. Turn off the appliance, remove the manometer and

tighten the test tapping screw.

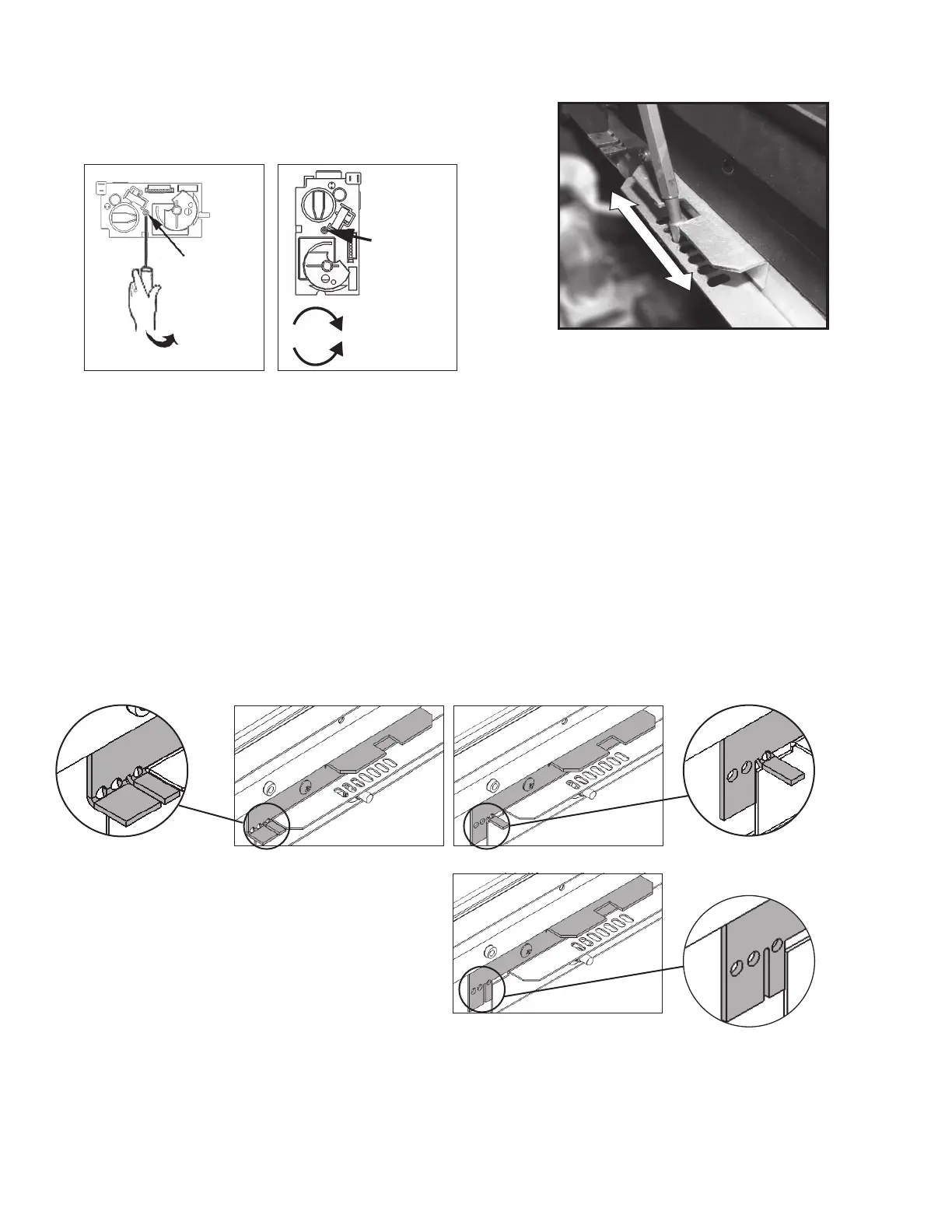

Adjust the air shutter

The air shutter lever is located in front of the fi rebox

behind the appliance front panel.

1. Tabs beside the lever must be repositioned accord-

ing to the gas used. With a screwdriver blade, bend

the tab pushing up or down according to the gas

used, as indicated below (these diagrams show the

aeration adjust in the fully closed position).

Front Face of Control Valve

Pry o

Plastic Cap

Front Face of

Control Valve

Pressure

adjustment

screw behind

plastic cap

Increases pressure

Decreases pressure

2. Adjust the shutter using a screwdriver as a lever to

slide the shutter left or right.

Complete the installation of the fi replace

Complete the installation of the fi replace following the

guidelines of the installation instructions supplied with

the appliance.

Fit the conversion labels

1. Fit the conversion label with new specifi cations

over the corresponding specifi cations on the data

plate located at under the short window on the card

marked Lighting/Operation Instructions.

2. Fit the label “This appliance was converted on... by...”

near the data label fi tted in 1.

3. Fit the label “This control has been converted...” on the

side of the appliance near the valve.

Closed

Open

Set air shutter

with a screwdriver

Designed and Manufactured by / for

Miles Industries Ltd.

190 – 2255 Dollarton Highway, North Vancouver, B.C., CANADA V7H 3B1

Tel. 604-984-3496 Fax 604-984-0246

www.valorfi replaces.com

Because our policy is one of constant development and improvement, details may vary slightly from those given in this publication.

LX1 and LX2 natural gas:

both tabs up

LX1 propane gas:

small tab up

LX2 propane gas:

both tabs down

4

Loading...

Loading...