10. Lever off the small domed cap covering the

manifold pressure setting screw, on front face of

valve cover by using a screwdriver or similar.

11. Refi t the module to the appliance.

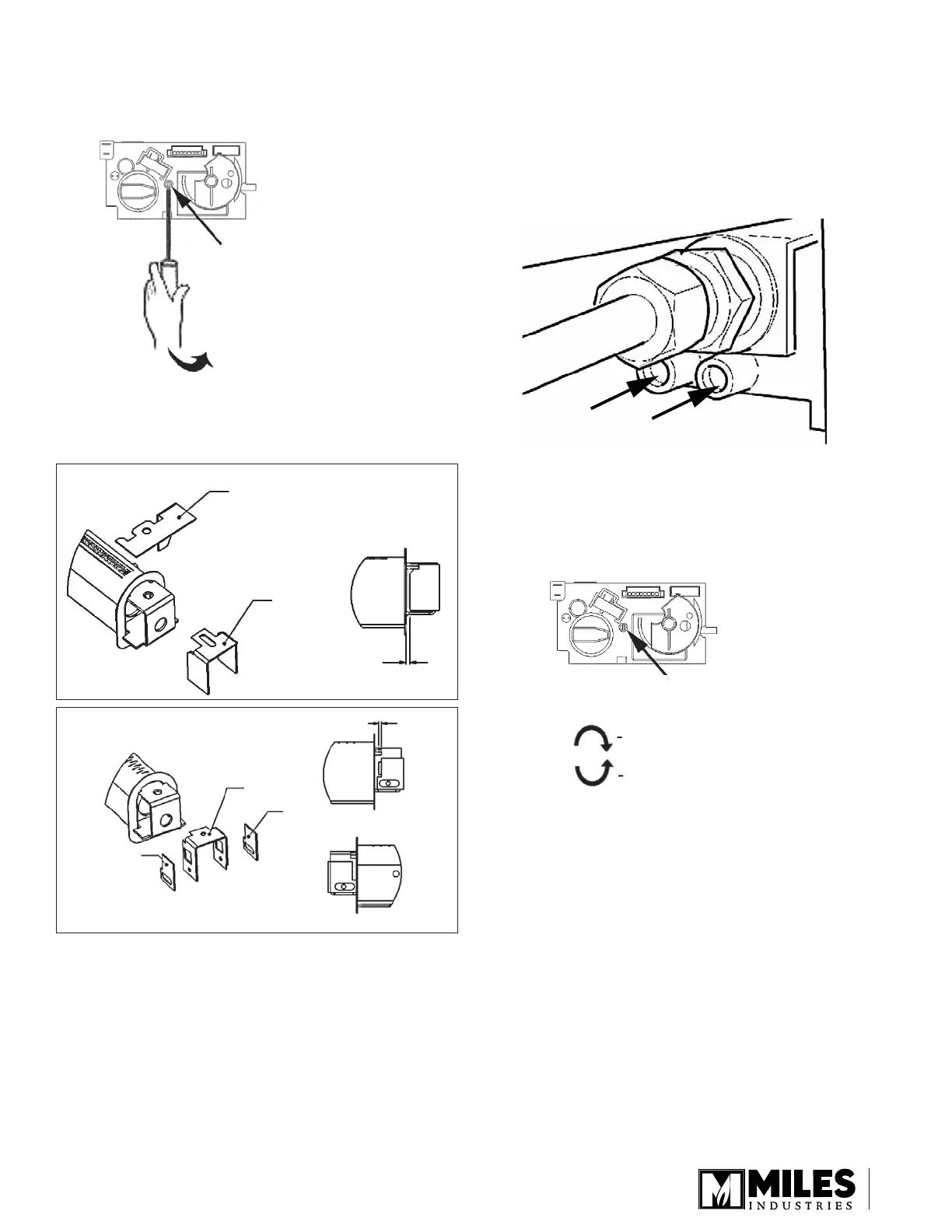

12. Fit the aeration shutter for the gas set as per

diagram.

Supply

pressure

test tapping

Manifold

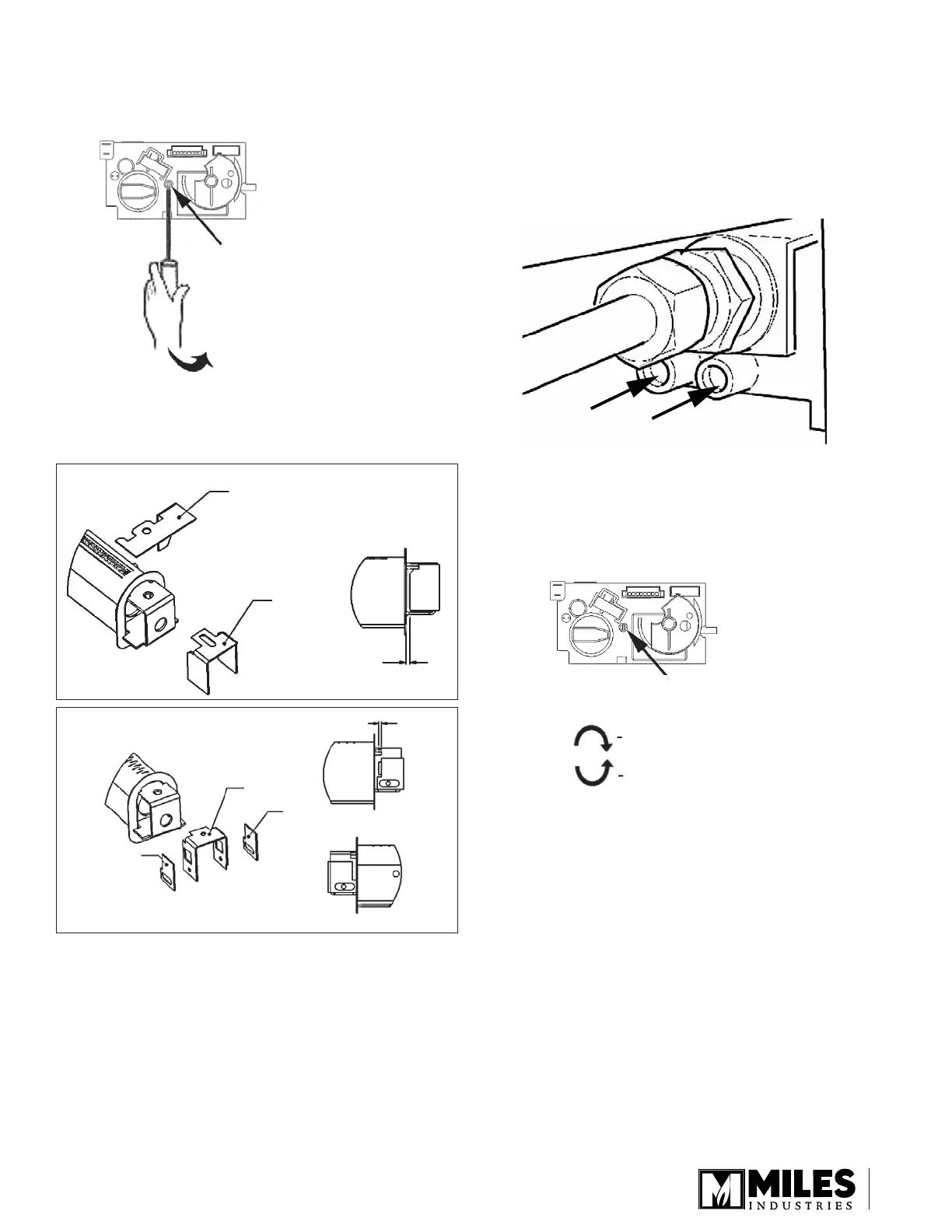

pressure

test tapping

Front Face of Control Valve

Pry o

Plastic Cap

Front Face of Control Valve

Pressure Adjustment Screw

behind Cap

Increases Pressure

Decreases Pressure

13. Turn on gas supply and check for leaks using

soap solution. The minimum and maximum gas

supply pressure are indicated on page 1 and can be

verifi ed using the inlet supply pressure test tapping.

14. Using a small straight blade screwdriver, back off

the plug screw within the manifold pressure test

tapping. Fit a manometer to the manifold pressure

test tapping.

15. Light the appliance and turn up to full fi re. Check

for leaks downstream of the valve. Adjust the

manifold pressure setting screw according to

specifi cations indicated on page 1.

16. Turn appliance off. Remove the manometer and

tighten the test tapping screw. Refi t the domed plug.

17. Fit the data conversion label and signed conversion

label close to the rating plate. Fit the control

conversion label near the controls.

18. Re-install all ceramics, check that the appliance

operates correctly. Refer to main instructions.

Designed and Manufactured by / for

Miles Industries Ltd.

190 – 2255 Dollarton Highway, North Vancouver, B.C., CANADA V7H 3B1

Tel. 604-984-3496 Fax 604-984-0246

www.valorfi replaces.com

Because our policy is one of constant development and improvement, details may vary slightly from those given in this publication.

3000371

530LPG

530NG

320B293

3000220

3000220

4000682

3 mm AERATION GAP

2 mm AERATION GAP

0 mm AERATION GAP

3

Loading...

Loading...