984

Model Code Page

64. Powered front axle

8. 11. 1990

6000--8750 644 4

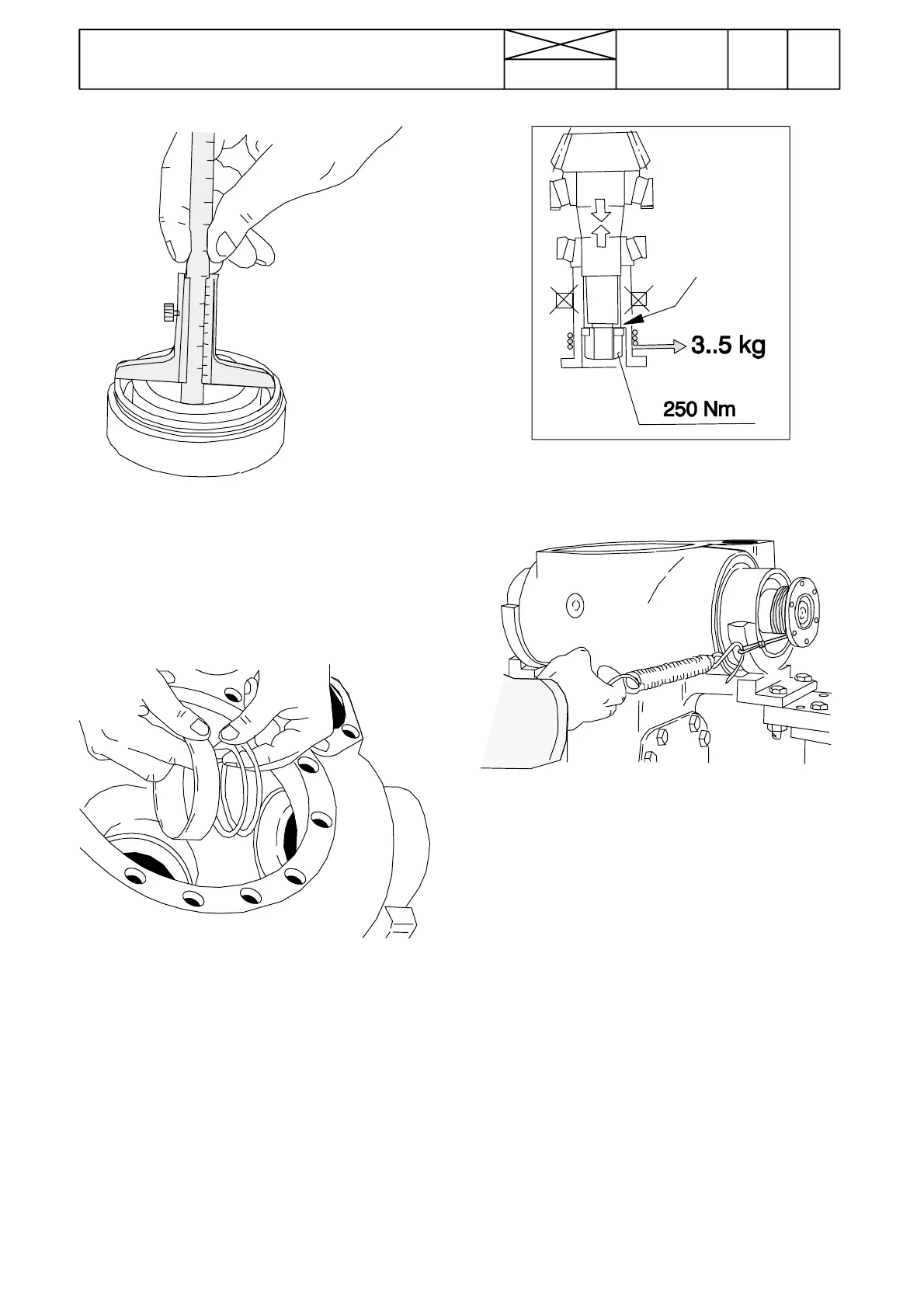

3. Measure the thickness of the inner bearing (largerbearing),

measurement H (e.g. 28,00 mm).

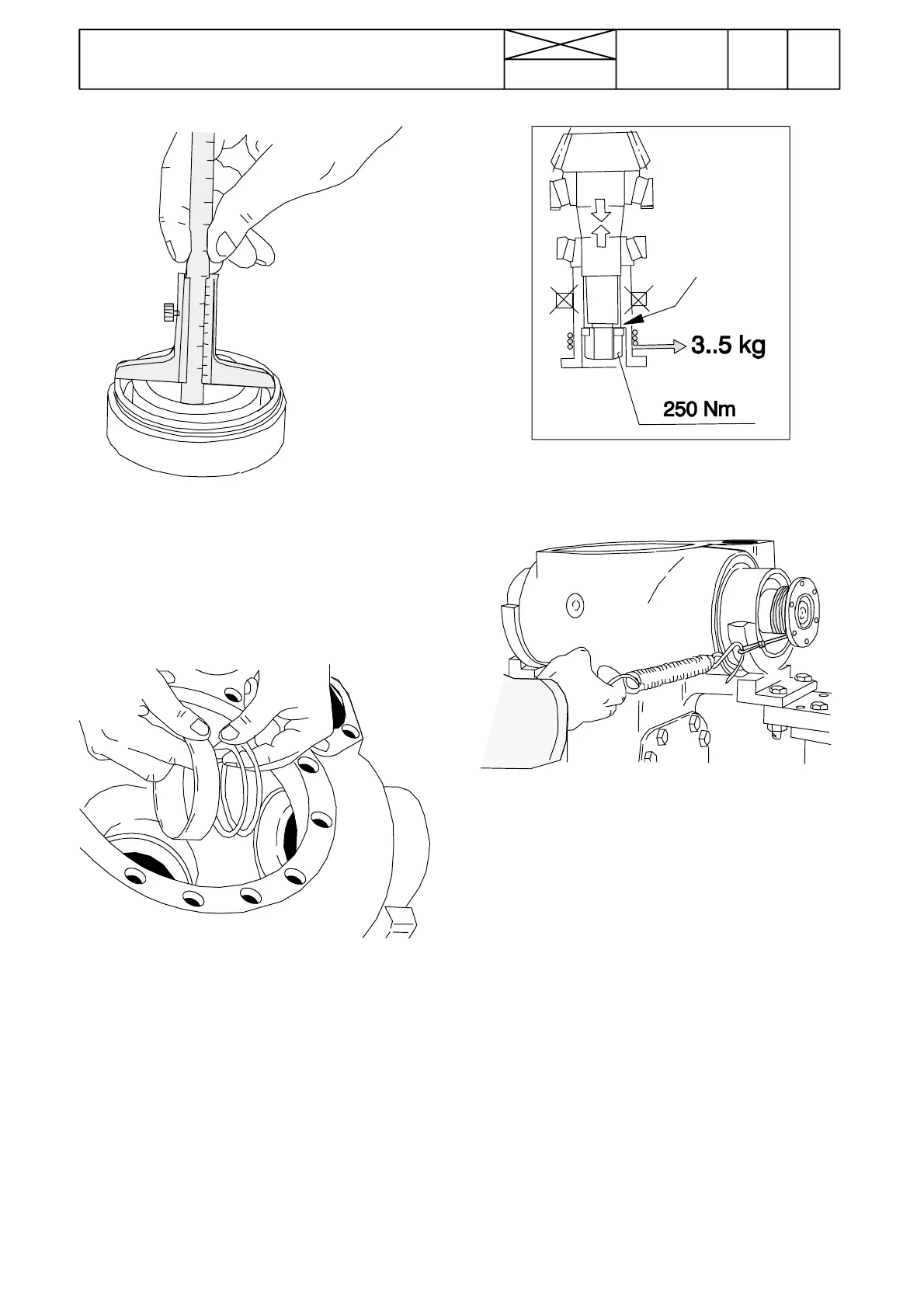

4. Calculate the number of shims required for correct pinion

shaft position:

S = C --- ( H + E ) =136,50---(108,00+28,00)=0,5 mm

5. Put the shims required under the inner bearing outer race

and fit the outer race against the shims. Fit the outer bearing

outer race.

6. Heatthe inner bearing to 80˚Cand fitit ontothe pinion shaft.

Push fully home.

7. Push the pinion shaft into the housing. Heat the outer bear-

ing to 80˚C and push it onto the shaft against the outer race.

Fit the circlip.

8. Fit the drive flange onto the pinion shaft (do not fit the seals

yet) and fit the shims, spacer ring and the nut. Tighten the nut

to 250 Nm.

N.B. Turn the shaft 20---30 revolutions before measuring the

rolling resistance and lubricate the bearings with oil.

s=0,15

0,2

0,5

Figure 6. Adjustment of pinion shaft bearing preload.

9.Useaspringbalance(seefigureabove)tomeasurethe

force needed to rotate the pinion shaft. The rolling resistance

should be 3 --- 5 k g . If the rolling resistance is not correct the

number of shims under the nut must be adjusted.

N.B. If the rolling resistance is too great more shims are re-

quired and vice versa.

10. When rolling resistance is correct the seals can be fitted.

Grease the lips of the seal with universal grease; fit a dust seal

in front of the seal.

N.B. Tool 893600 can be used when fitting the seals.

11. Fit shims, spacer ring and drive flange; tighten the nut to

250 Nm.

Loading...

Loading...