204 Heavy Duty Combination Brake Lathe

OPERATION (continued)

CHATTER CONTROL

1. Brake drums are dish or bell shaped and have a tendency to chatter. This can result

in a wavy or chatter finish accompanied by excessive noise. THE VIBRATION

DAMPENER BELT MUST BE USED AT ALL TIMES to prevent chatter. Securely

wrap belt around the outside of the drum or use proper “O” ring type on outside of a

rotor.

2. Dull, broken chipped or improper tool bits will cause chatter. ALWAYS use tool bits

supplied by the original manufacturer as they are designed to do a specific job.

3. A loose carbide tip on the tool holder will cause chatter. Make sure screw holding

carbide tip grips tip firmly.

4. A dirty uneven surface will crack the carbide tip and/or chatter.

TOOL BITS

1. This lathe is supplied with replaceable type throw-away carbide tips, part no. 804-

8665-62 (Figure 6) for the drum cutters and part no. 804-8665-61 for the rotor

cutters, (Figure 7).

Figure 6 Figure 7

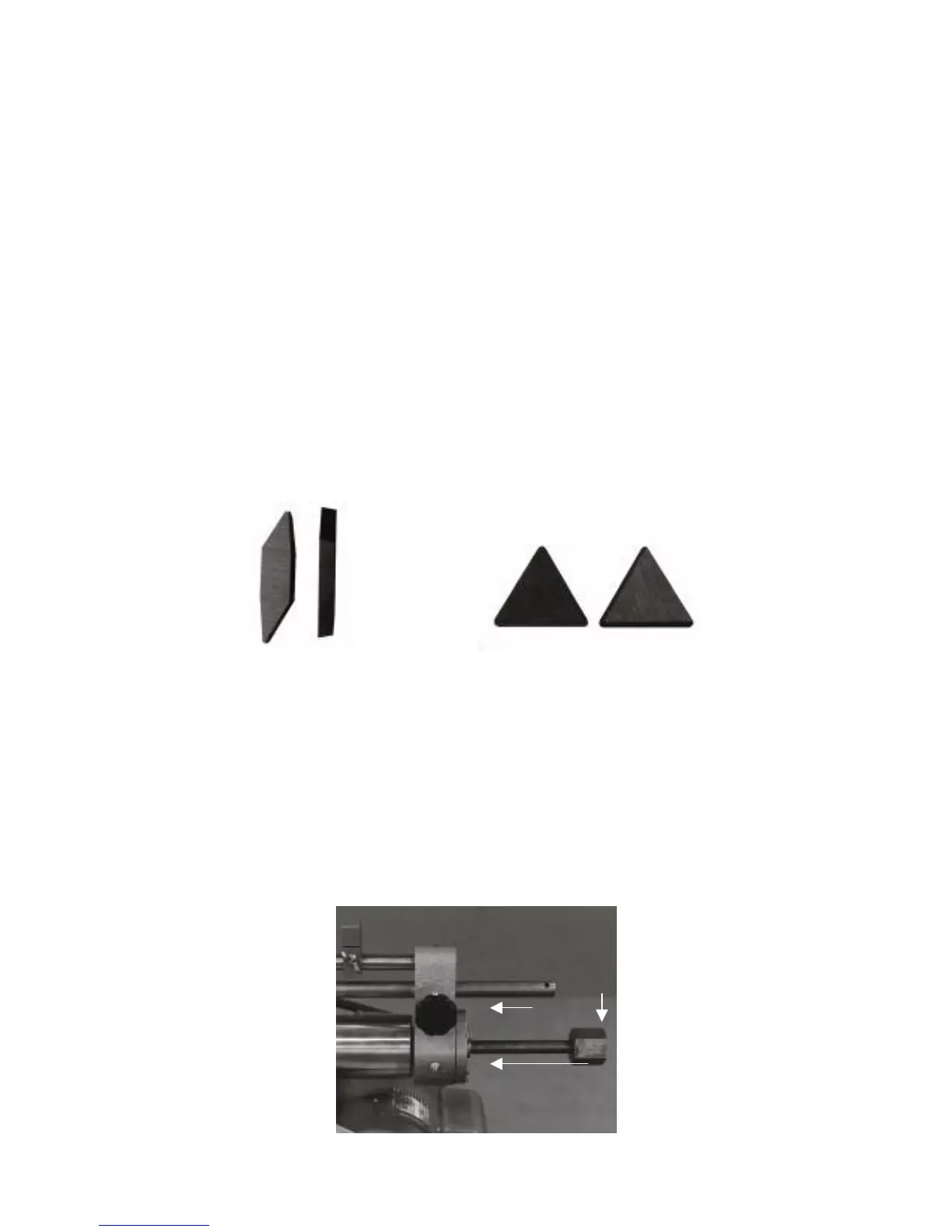

INSTALLATION OF ARBOR

1. Select correct size mandrel for the work to be done, either a 1" diameter for work that

is 150 pounds or less or the heavy-duty 2" mandrel for work 150 to 500 pounds.

2. Slide mandrel into spindle taper.

IMPORTANT: Both mandrel and spindle tapers must be clean or else mandrel will

run out and taper may be damaged. Align pin in mandrel with slot in main spindle.

Screw in draw bar (Figure 8A), and lock tightly. DO NOT tighten excessively. Driver

pin will prevent arbor from slipping. Remove mandrel easily (Mandrel has non-

locking taper) by loosening nut then tapping lightly into the draw bar.

Loading...

Loading...