204 Heavy Duty Combination Brake Lathe

OPERATION (continued)

RECONDITIONING DRUMS

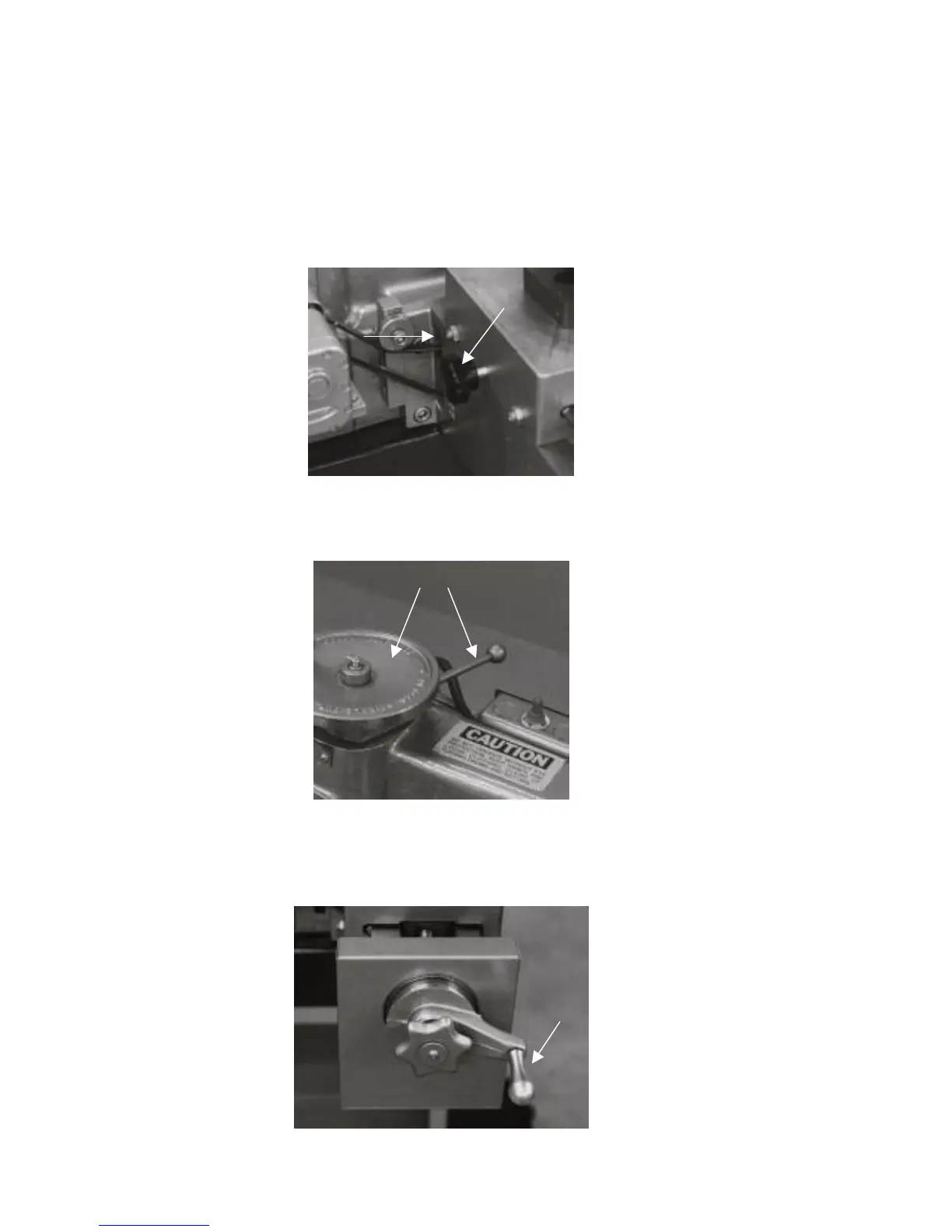

1. The knob (Figure 8B) should be loosened when turning drums to insure spindle will

move out during operation. This screw must be tightened when cutting rotors.

2. This knob (Figure 9) should be tightened when doing drums and slide is in position.

Loosen when cutting rotors.

Figure 9

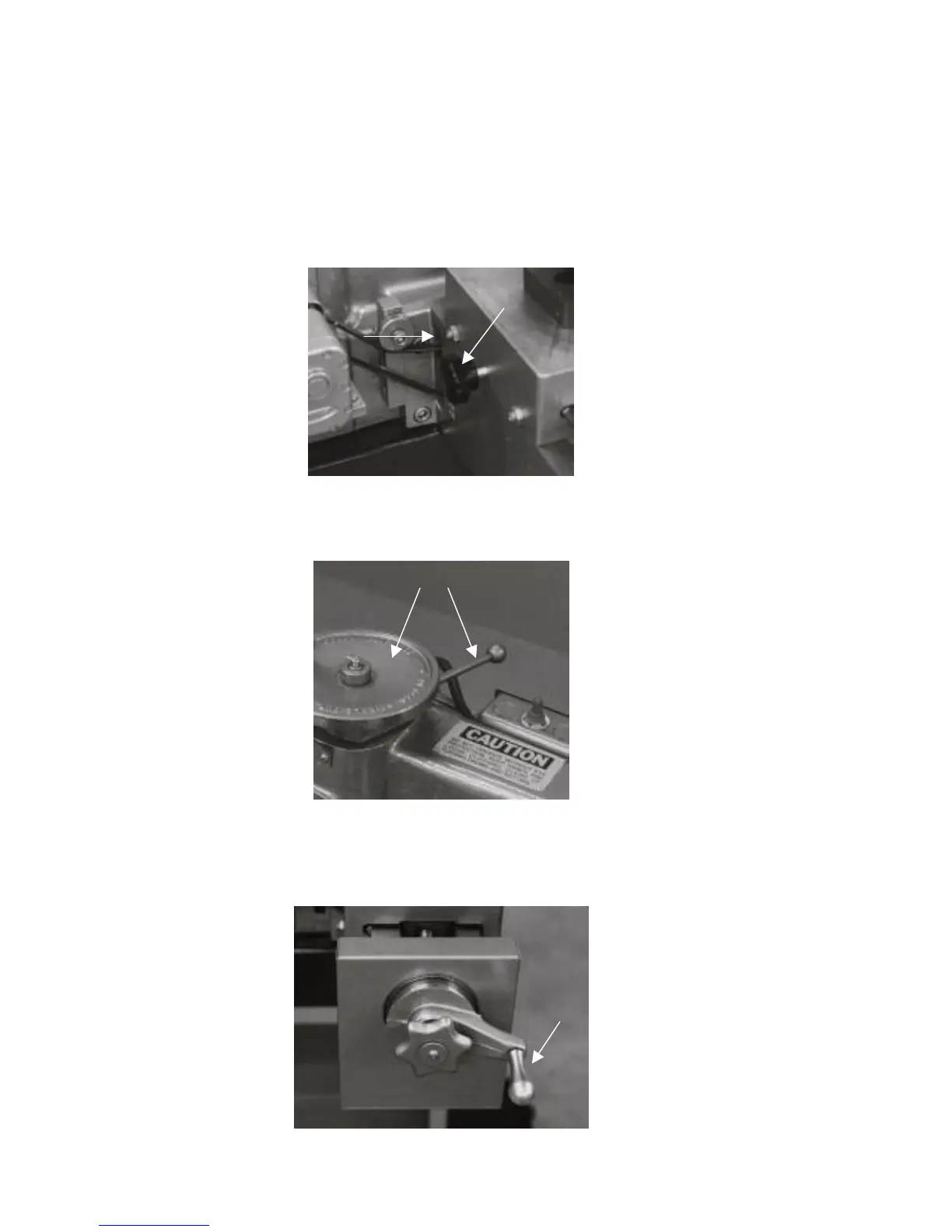

3. To engage feed of main spindle push lever (Figure 10A), to the right of handwheel

(Figure 10B), is the main control to move the main spindle “in” or “out”.

Figure 10

4. Crank (Figure 11) is used for moving the tool bit into the brake drum on the 204S.

This crank is graduated into thousandths and is direct reading. Example: If crank is

moved out .030", drum will be enlarged .030".

Figure 11

Van Norman 14. 888-855-1789

Loading...

Loading...