44

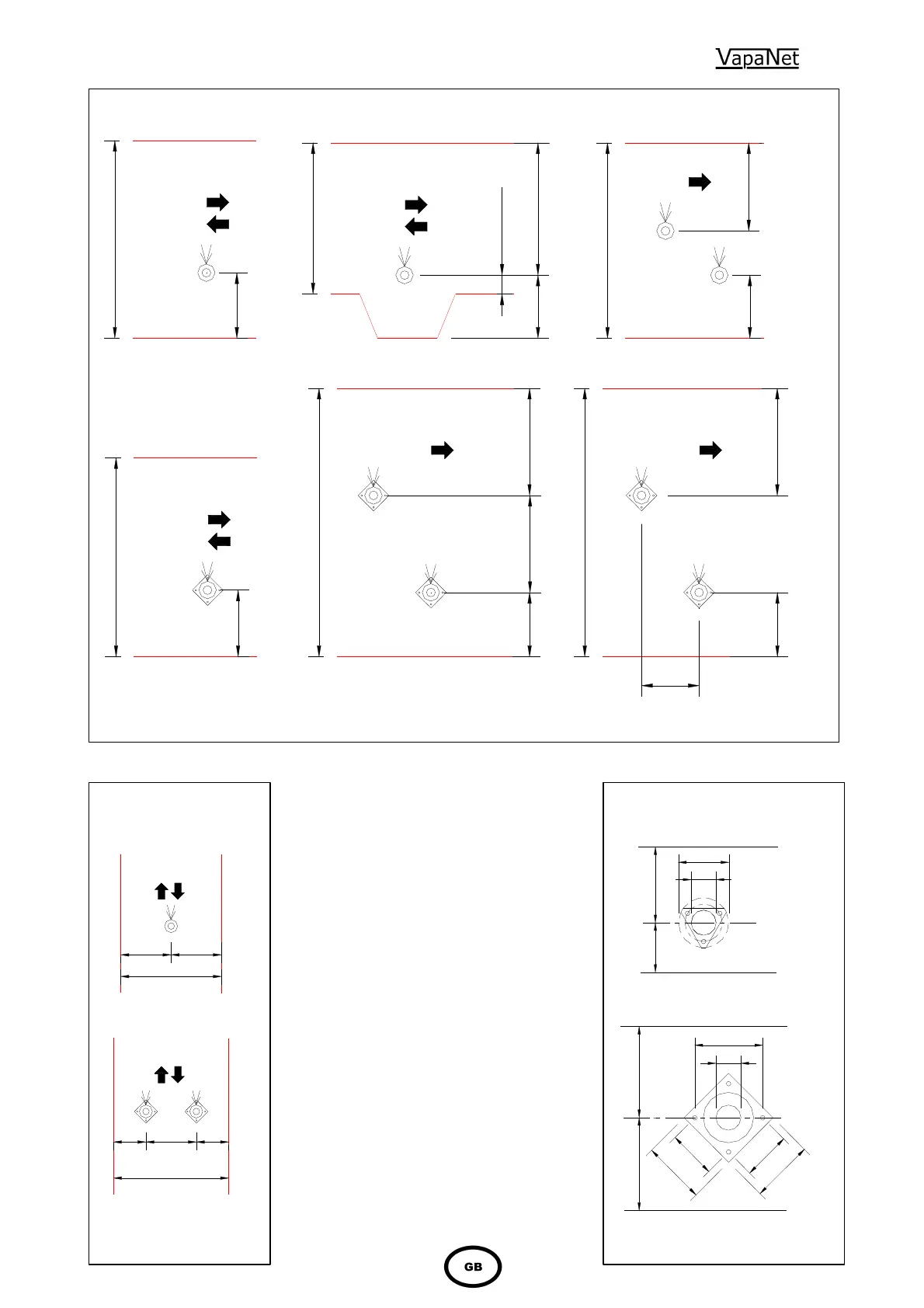

33% H

H > 300

H < 300

80 200 min

30 min

25%H

H > 350

50% H

80 min. 200 min.

33% H

H > 375

H > 600

20% H

40% H

40% H

30% H 60% H

H > 400 < 600

250 min.120 min.

200

35 Ø 1 Steam Pipe 35 Ø 1 Steam Pipe 35 Ø 2 Steam Pipes

54 Ø 1 Steam Pipe 54 Ø 2 Steam Pipes 54 Ø 2 Steam Pipes

Fig 2

Fig 4

50% W 50% W

W > 200

W > 200

25% 25%50%

35 Ø or 54 Ø

1 Steam Pipe

2 Steam Pipes

35 Ø or 54 Ø

Fig 3

shows the versatility of the steam

pipe / steam hose steam delivery system. It

also indicates where and how condensate

traps / condensate separators should be

used. If the steam pipe slopes such that the

steam connection is lower than the far end of

the pipe, this indicates that a reverse slope

steam pipe is required. This is fitted with a

drain point to allow condensate to be taken

away to a convenient drain.

Figure 2 shows recommendations on how to

space one or more steam pipes in a

horizontal duct.

Figure 3 shows recommendations on how

steam pipes should be spaced in a vertical

duct

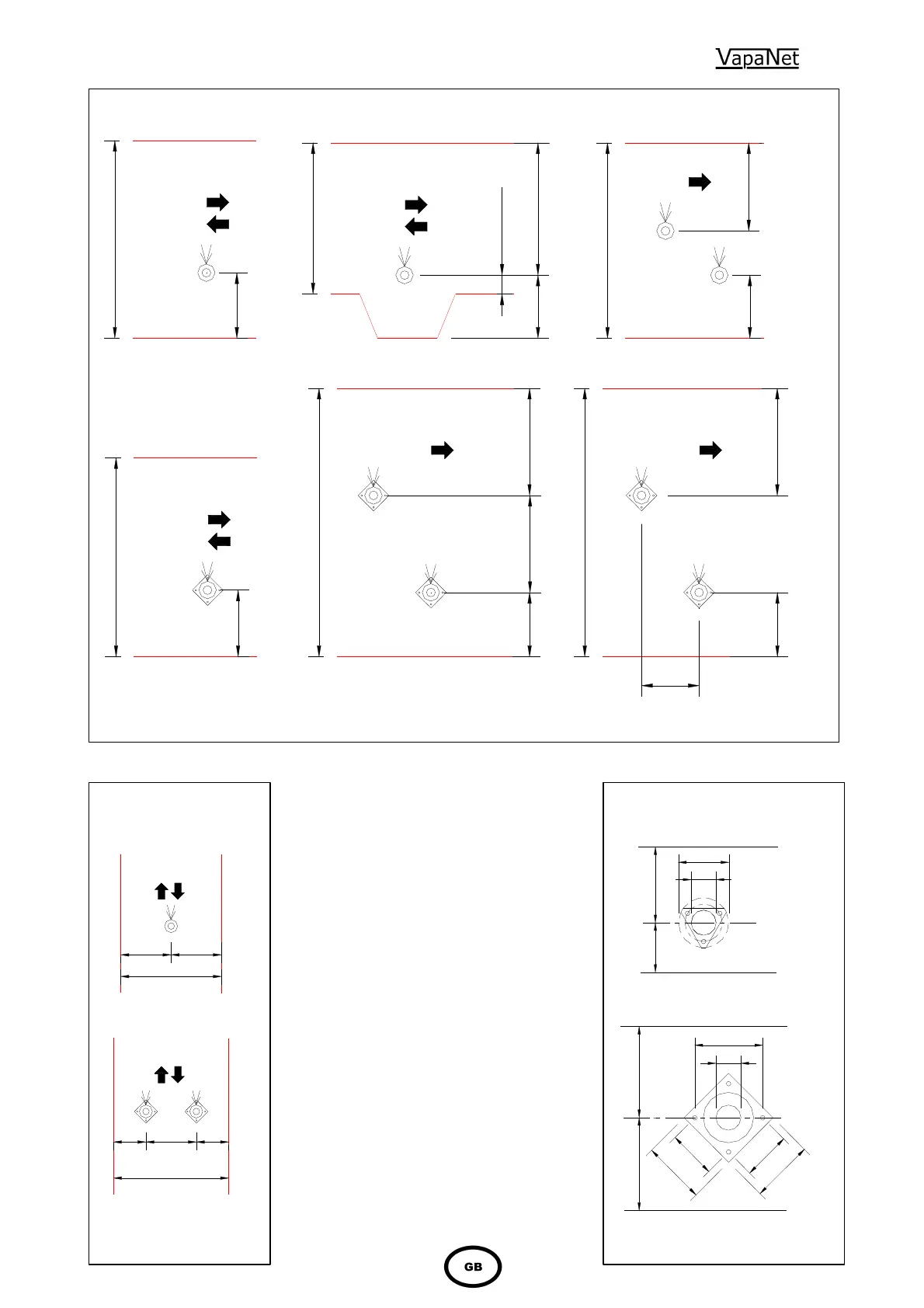

Figure 4 shows mounting details for 35 and

54 Ø steam pipes

NB. The duct should be clear of obstructions,

transformations and bends until the steam

has been absorbed into the airflow. A guide

to calculating this distance is available from

Vapac – Part Number 0411047.

October 02

65

80

1

2

0

120

150

150

170 PCD

150

min 80

min 120

min 200

min 250

DUCT MOUNTING DETAIL

For 35 Ø Steam Pipe

For 54 Ø Steam Pipe

DUCT MOUNTING DETAIL

3 x 5.0 Ø

Fixing

holes on

120 PCD.

170 PCD.

holes on

Fixing

4 x 6.4 Ø

Loading...

Loading...