19

1

2

4

5

6

7

8

9

10

11

12

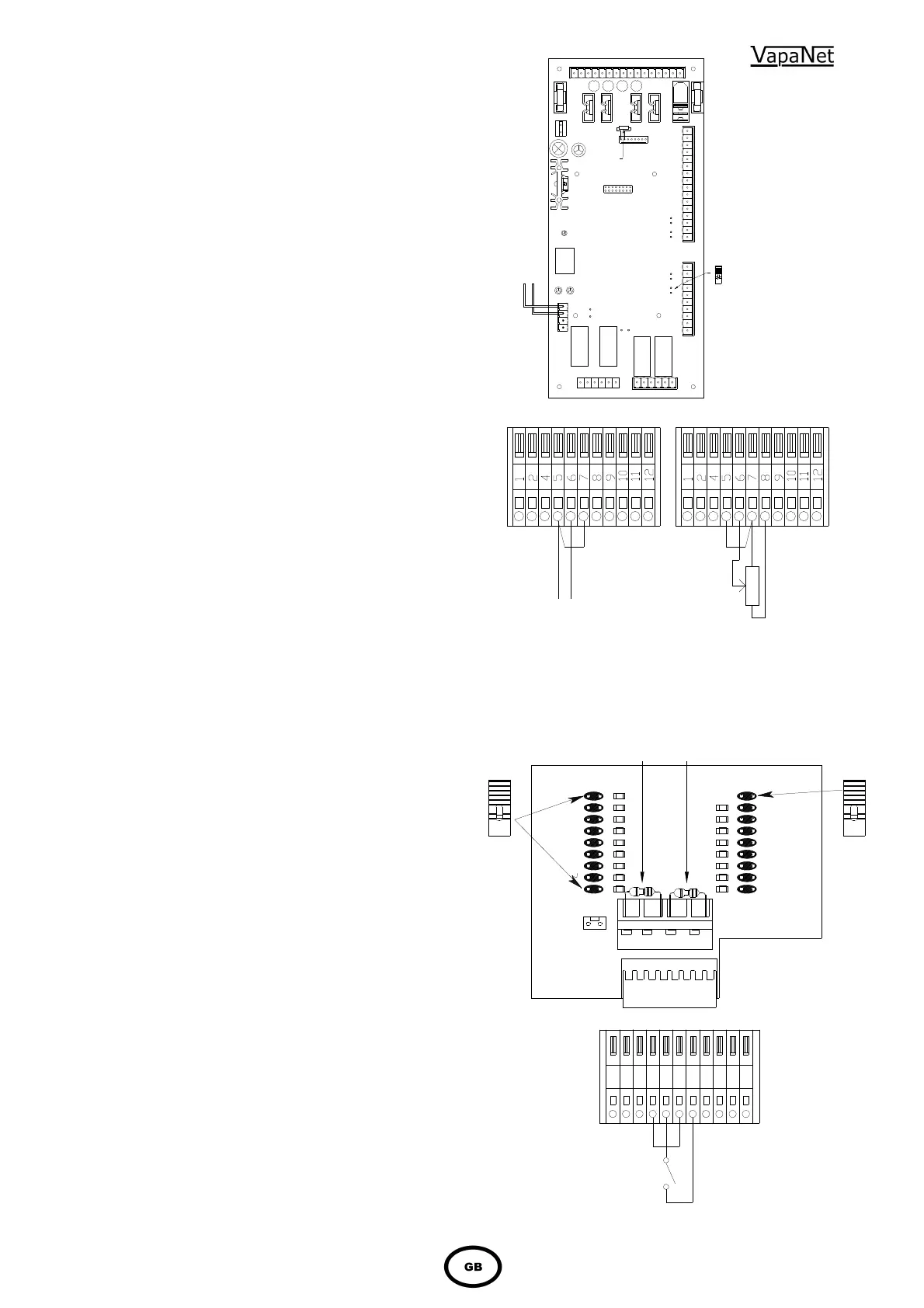

HYGROSTAT WITH VOLT FREE CONTACTS (max.

RESISTANCE OF EXTERNAL CONNECTION 100

Ohms.

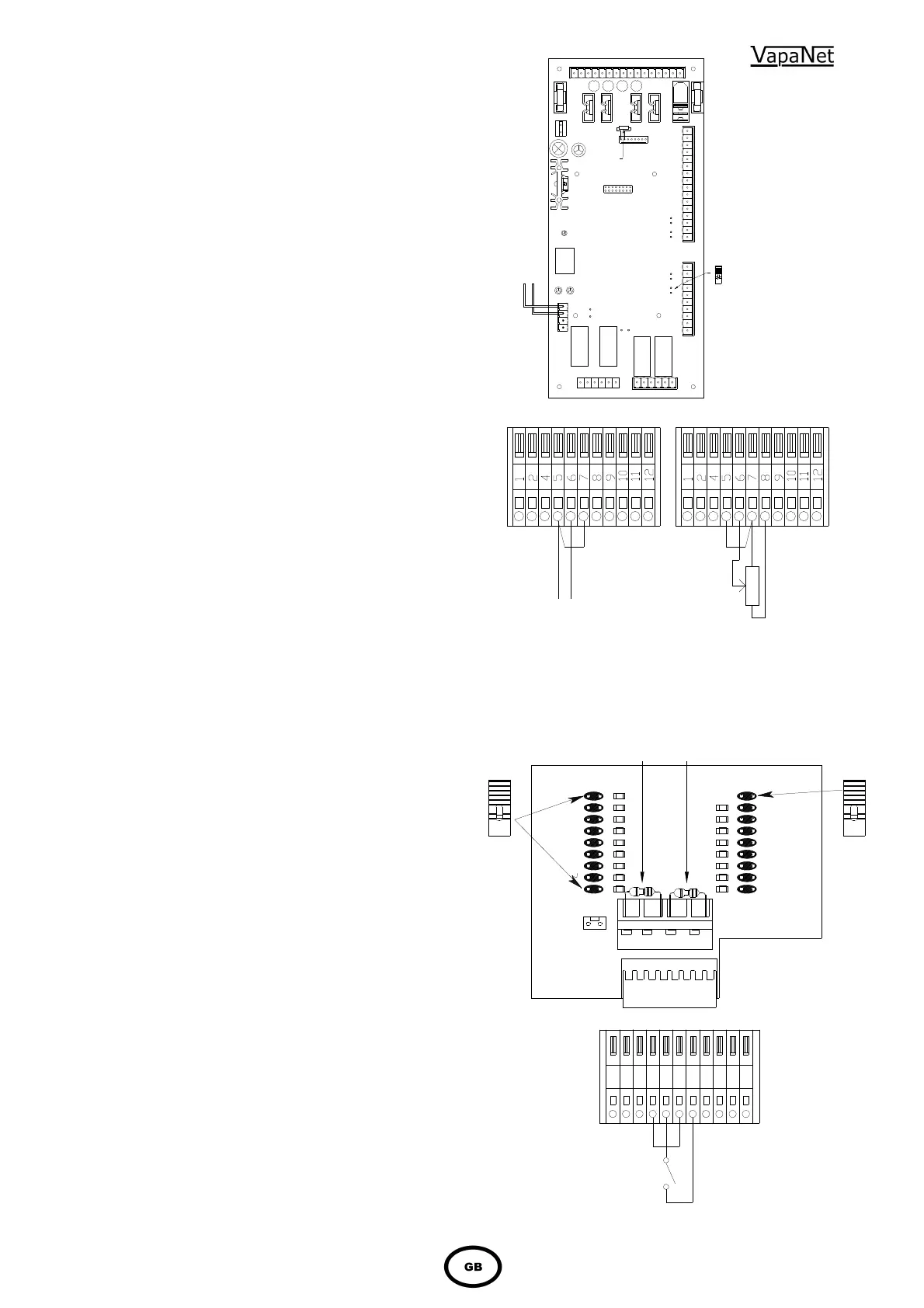

1.6 Control Circuit Connections

1.6.1 Control Circuit Wiring

Use a dedicated, earthed metal conduit for both the

control signal cable and the security circuit cables,

sharing the same conduit if practicable.

Use screened cable for all control and security circuit

connections to minimise risk of electrical interference.

The screen should be grounded at the VAPANET end

only. See detail on page 7. NB. The control signal

should be connected to ground at the PCB by

connecting either terminal 5 or 6 to terminal 7 –

I

mportant note if the controller output is

referenced to ground, then the “leg” which is

ground must be the one linked to terminal 7.

1.6.2 Proportional Control

The VAPANET Electrode Boiler (LExxP) models can

all be operated by either a potentiometric signal, a

lonworks network signal or by one of 6 standard

proprietary DC analogue signals.

Input signal:

Potentiometric control

0-5V

0-10V

0-20V

(Actually 0-18V – not phase cut)

2-10V

1-18V

4-20mA

(Ensure jumper J1 is in place)

Network

(Slave unit – demand generated by

Master)

Response:

8-100%

1.6.3 Control Signal Selection

Selection of the control signals is done a part of the

initial set-up procedure using the keypad display. For

confirmation that the signal has been selected, view

the information window. If the unit has not got a

keypad then this is done on the configuration board

1150634 mounted on the main control board 1150630

using the jumpers provided. The top right hand link

should be made indicating that the unit is an

“Electrode boiler” and the appropriate left hand link

representing the actual site control signal should be

linked using the jumper plugs provided

1.6.4 On/Off Control

Vapanet models can be operated by a single

step humidistat which has Volt-free contacts –

select control option Pot.

DC 0 - 20 4 – 20 Ma POTENTIOMETRIC

VOLTAGE CURRENT CONTROL

CONTROL CONTROL min. 135 Ohms

Max. 10,000 Ohms

NOTE :- FOR CURRENT INPUT ONLY JUMPER J1 ON THE

1150630 CONTROL BOARD MUST BE LINKED.

Jumper J1

should be

fitted if

control

signal is

4 – 20 mA

Vapac PART No. 1150630

16

CR6

1

NetCR7

J6

CR5

1

6

6

10

CR3

16

J1

J2

J3

1

F2

CR1

1

F1

CR2

J4

18

CR4

1

16

J5

CR2

configuration

resistor

CSP

CR2

J1

Vapac part no. 1150634

Electro

boiler

Pot high

Pot medium

Pot low

Softened

De-iron

De-min

0-5v

0-10v

2-10v

1-18v

0-20v

4-20mA

pot

Full o/p

or slave

Network

J2

UCP1UCP2

Loading...

Loading...