d) Fill the hub inside with new grease (e.g. for water pumps) lubricating at the same time

also the flange with balls and free wheel surfaces.

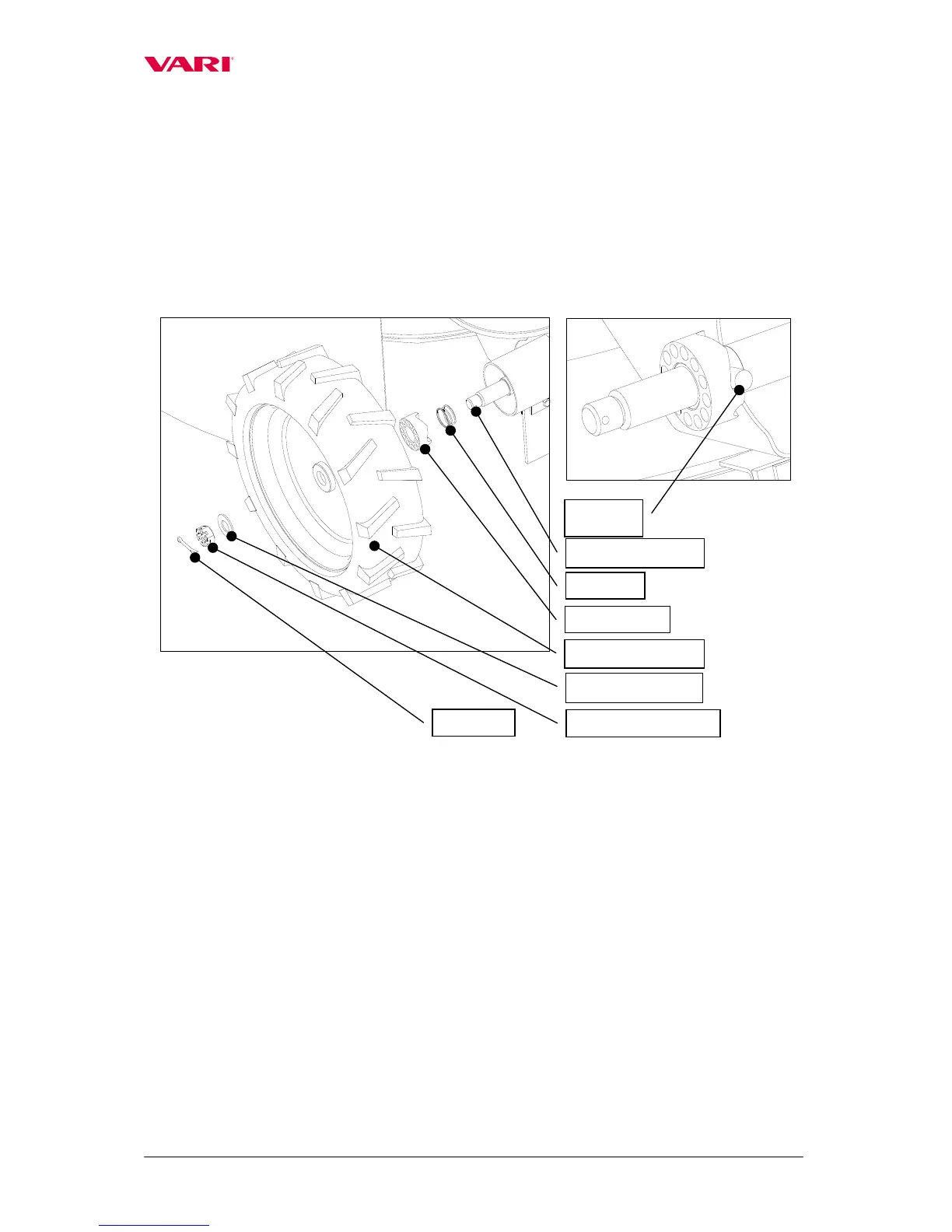

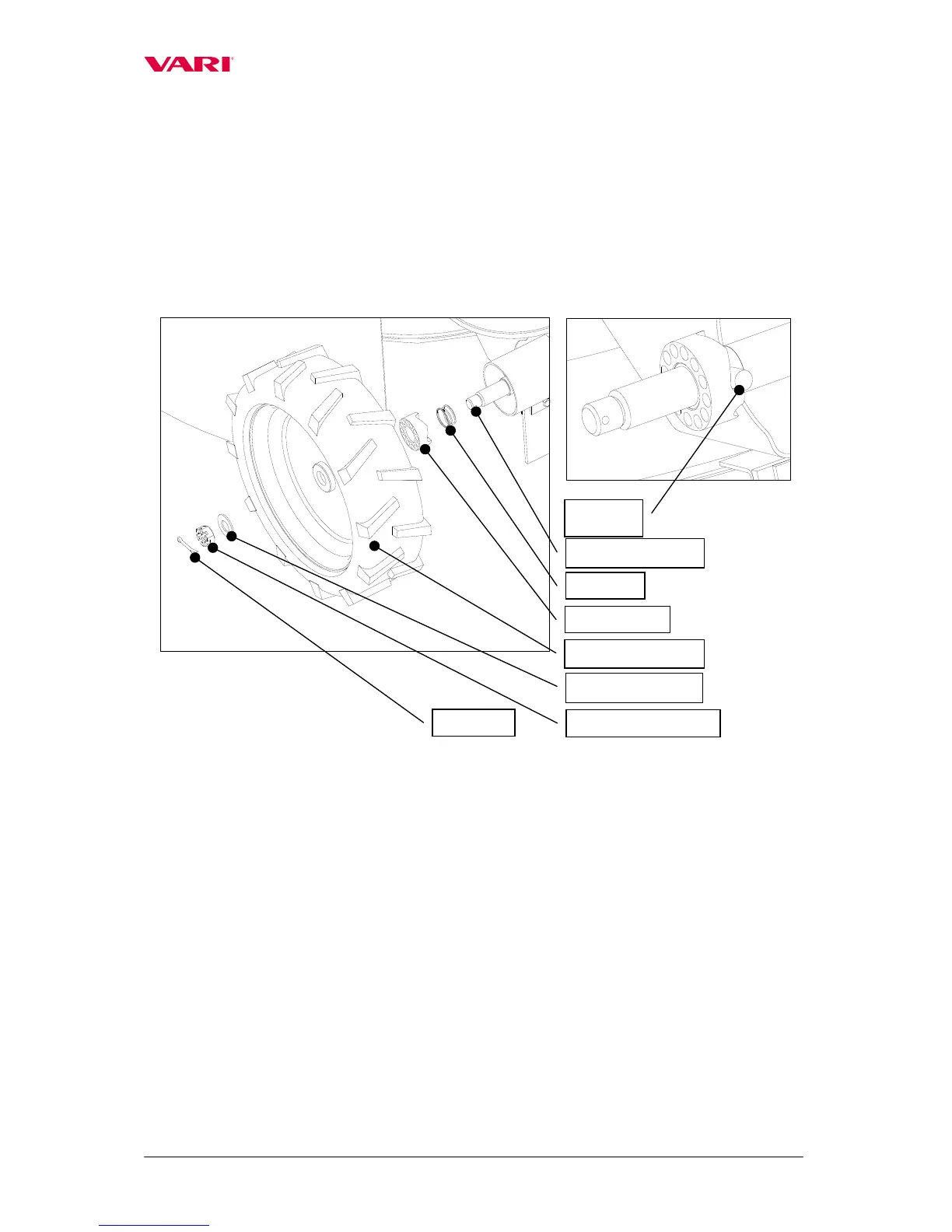

e) Slide the free wheel on the wheel axis. The pin driven into the wheel axis must lean

against the inclined surface on the free wheel (see Fig. 9). Put the wheel onto the axis,

screw the nut to the stop; then release it by one split pin groove and secure the connection

with a new split pin. The wheel must freely turn with no great axial clearance.

f) Check of correct free wheel assembly: Press the machine travel gear clutch lever, turn the

driving wheel by hand in the direction of forward travel. The free wheel must be clicking.

7.9 Machine storage

Prior to any longer storage, clean the machine from all dirt, debris and plant residues.

Repair damages on painted machine parts.

When putting the machine out of operation for a longer time, it is advisable:

a) to conserve knives on the mowing disk;

b) to drain petrol from the engine fuel tank and from the carburetter (more

instructions see guidelines for engine operation).

Prevent access of unauthorized persons to the machine. Protect the machine from

weather impacts but don’t use air-tight protection due to a possibly increased corrosion under

it.

7.10 Disposal of packaging and machine after service life

expiration

After unpacking the machine, you are obliged to provide for the disposal of packaging

with the use of secondary raw-materials according to Waste Law No. 185/2001 Gaz. (as

amended) and with respect to the decrees of local town or municipal authorities.

Loading...

Loading...