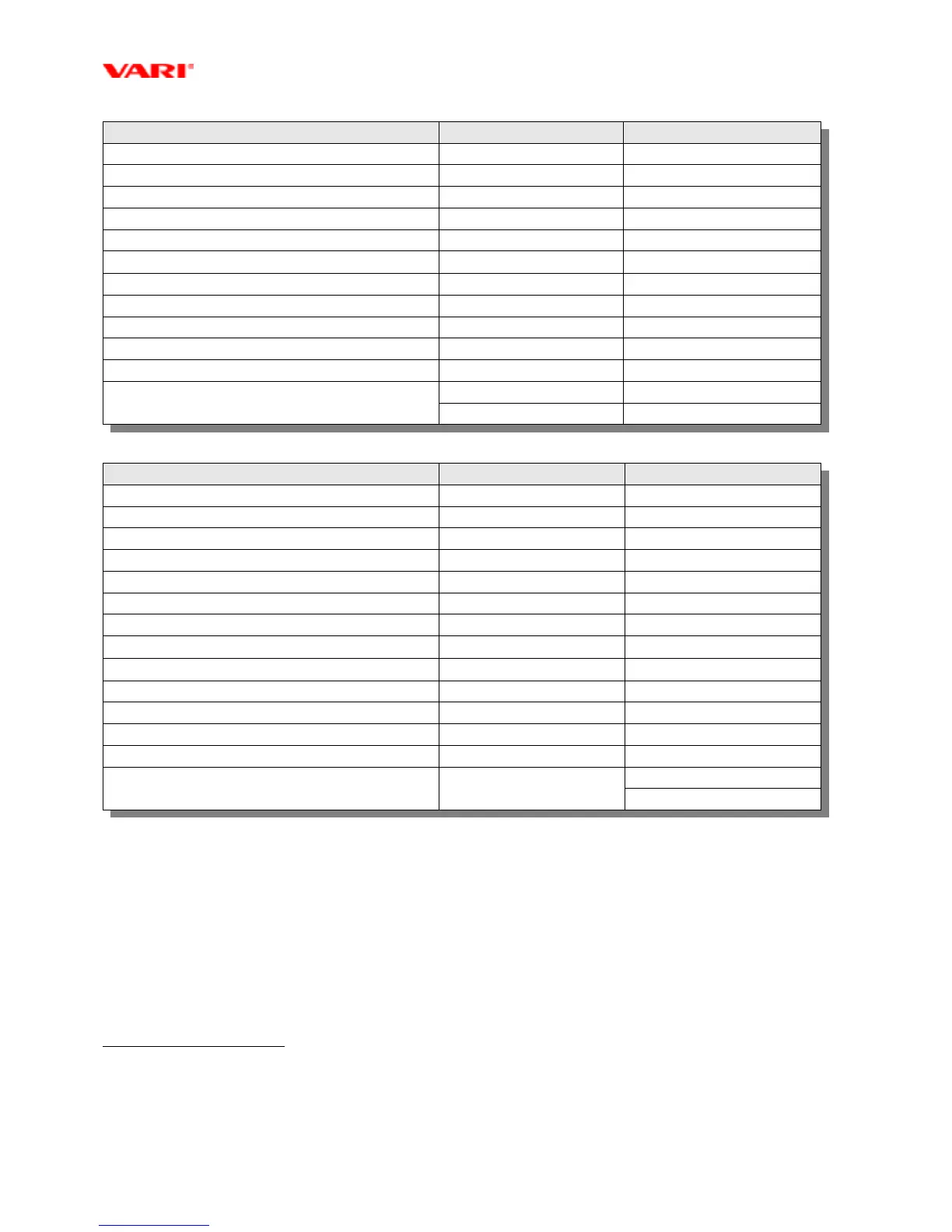

BDR-620

2.3.1.1 Technical information

BDR-620D Unit Value

Length mm 1730

Width (including the side screen) mm 795

Height mm 1191

Weight kg 61

Maximum cutting width cm 62,2

Safe climbing ability

∠

10°

Cutting disk revolutions

40

min

-1

1964

Maximum blade circumferential velocity m.s

-1

64

Travelling speed km.h

-1

2,5 - 3,4

Area capacity

41

m

2

.h

-1

1555-2114

Gearbox oil capacity l (litre) 0,025

Gearbox oil quality

API GL-4 (GL-5)

SAE 90 (80W-90)

Tab. 3: Technical information for BDR-620DEngine information

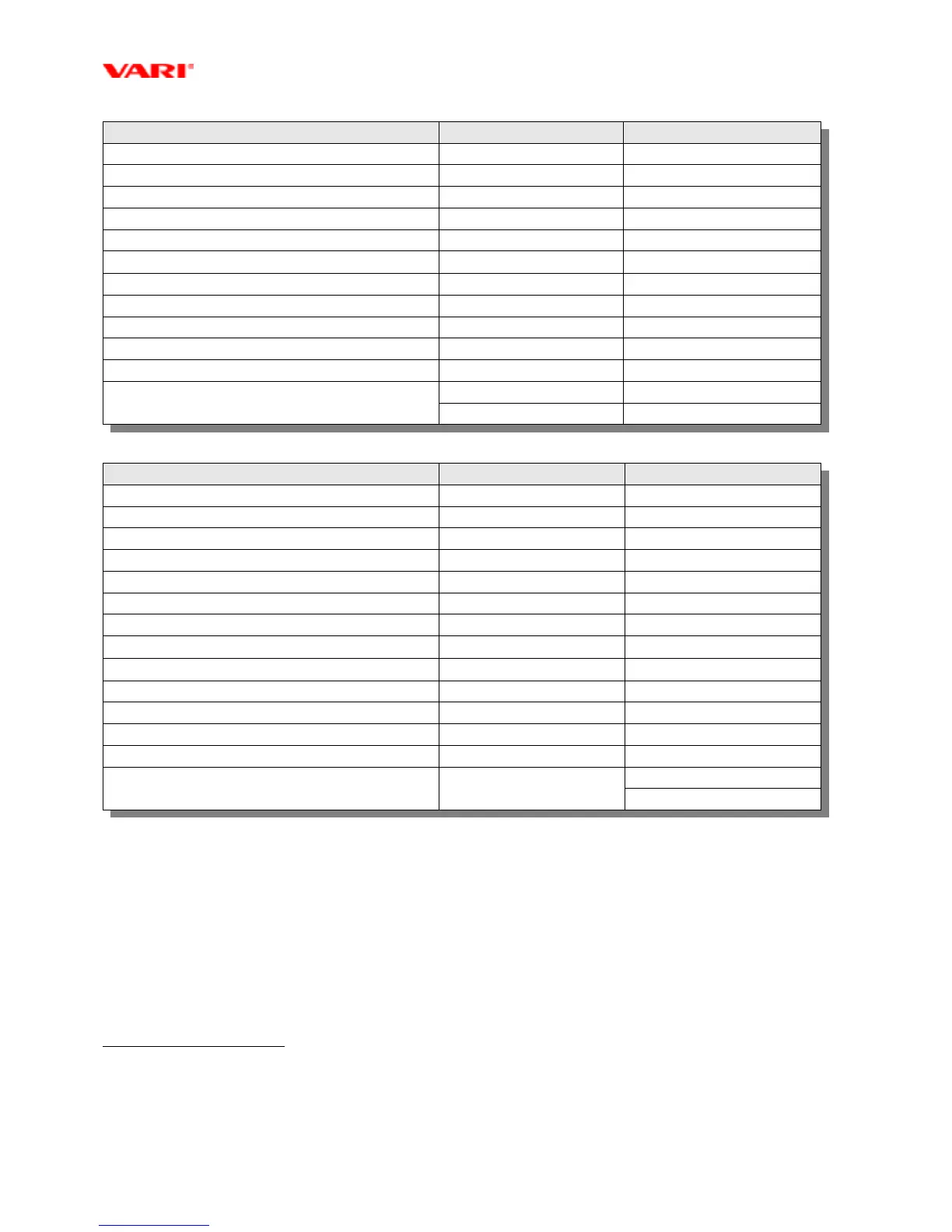

Engine Unit Value

Type - HONDA GCV-190

Engine displacement cm

3

187

Bore x stroke mm 69 x 50

Max. power/at rpm (HP)

42

kW/min

-1

(HP) 3,8/3600 (5,1)

Max. torque/at rpm

43

N.m/min

-1

11,3/2500

Maximum (set) engine rpm min

-1

3200 ± 100

Fuel consumption l (litre) 1,3 per 3000 rpm

Maximum engine tilt (long period)

∠

20°

Maximum engine tilt (short period

44

)

∠

30°

Fuel tank volume

45

l (litre) 0,91

Fuel (unleaded) petrol okt.č. 91-95

Engine oil filling l (litre) 0,55

Oil quality SAE 15W-40

Ignition plug -

NKG BPR6ES

BRISK LR15YC

Tab. 4: Engine technical information

2.3.2 Description of the machine and its parts

Drum mower BDR-620 (Pict.2) is built on a steel frame, to which all important parts of the machine are attached. All controls (1,2 and 4) are placed

on the handlebars. Handlebars are attached to the frame with a bolted connection (3) and their height is adjustable into 3 positions. Handles (12) secure a

firm grip and machine handling during work. On the left side of the handlebars, there is the wheel drive clutch lever (2) which controls the movement of

the machine in forward direction. On the right side, there is lever (1) of the disc drive clutch for turning the cutting disk drive on (off). Both control levers

return to their original position when the handlebars are released in a critical situation and disconnect the engine power transfer. The cutting disk is

equipped with an automatic brake

46

which stops the disk. Engine speed is controlled with an accelerator lever (4). The wheel drive is controlled by

worm-gear unit with a belt clutch which provides fluent power transfer onto the wheels (15) (the machine does not start with a jump). The gearbox and

clutch are covered by a plastic gearbox cover (16). There is the cutting disk (7) with four steel blades (8) in the front part. The attendant is protected

against flying parts of the cut stand by plastic cover (10 and 9). A detachable side screen (6), which is attached with a bolted connection (5), controls the

line spacing.

40 Actual rpm. of the disc when not cutting, including belt transmission losses.

41 Square meters cut per min./hour will vary, depending on the type of the stand.

42 Measured according to new Society of Automotive Engineers (SAE) J1349 standard

43 Measured according to new Society of Automotive Engineers (SAE) J1349 standard

44 Short period – up to 1 minute.

45 Measured according to new Society of Automotive Engineers (SAE) J1349 standard

46 The automatic break is an active protective feature that supports the machine’s safety.

20

Loading...

Loading...