BDR-620

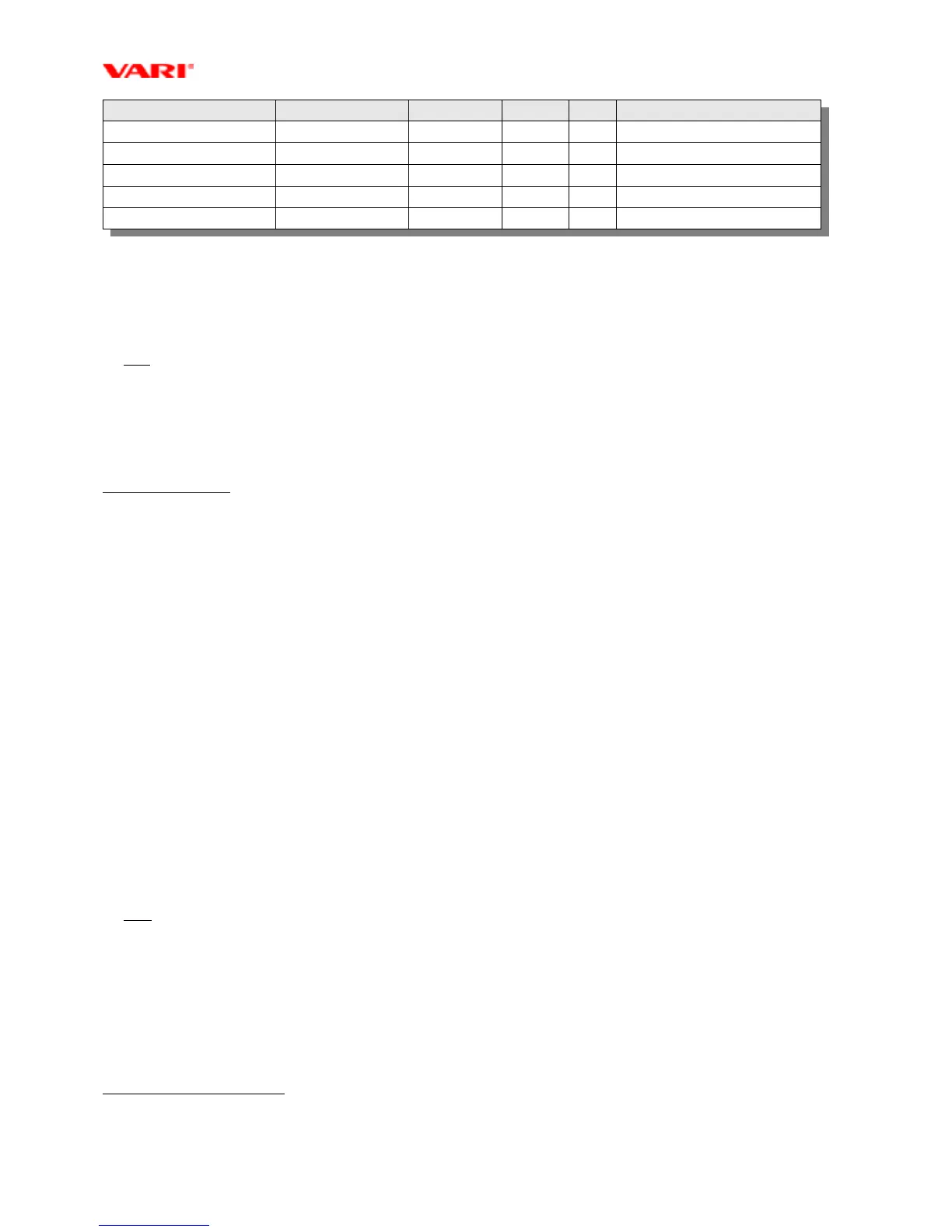

Lubricating point – description Seasonal interval After the season Lubricant Picture Note

Bowden cables min 2x (5 drops) yes oil Pict.9 Cable entrance into cable housing

Disc drive pulley casing every 10 hours (2 drops) yes oil/grease Pict.6 After nut and washer dismounting.

Wheel drive clutch pulley every 10 hours (2 drops) yes oil/grease Pict.7 Contact area with frame.

Cam every 10 hours (2 drops) yes oil Pict.8

Bolted connections - yes grease - Handlebars and side screen attachment

Tab. 5: Lubricating intervals

2.5.3 Work blades service and exchange

Seek authorised service in case you lack appropriate manual skills.

If the work blades are deteriorated or damaged and causing cutter vibrations, it is necessary to renew or exchange the blades

52

.

Note: he manufacturer bears no responsibility for damages caused by/on the cutter in case of a botched-up blades repair or when original parts are not

used. A sign identifying the manufacturer is imprinted in the blade and it is used as a proof of a genuine part.

The cutter must be secured from unexpected spontaneous movement and stand on a safe pad to allow adequate access to the blade.

Pay special attention when dismounting the blades. The cutting blades are sharp. Protect your hands with work gloves.

The engine must be off and the end of the spark plug cable must be taken off!

Proceedings (at the Pict . 5 ):

1) Hold the upper disc (1) so that it does not spin and use tubular wrench n.16 to dismount the bolted connection (3,4,5,6) of the blade. First

unscrew the nut (6), than the bolt.

2) Take the blade (2) and its parts out of the cutting disc. Align the blades and sharpen them. The blade slope should hold 30º angle with the

bottom blade level.

3) Check all blade parts for visible marks of damage. In case of damage, exchange the part with a new one.

4) Tighten the blade seating back. Tighten the bolt (3) firmly

53

. Secure the bolt from loosening with a nut (6).

If some of the blades are bended or deteriorated you must exchange all cutting disc blades!

2.5.4 Belt transmission – automatic brake

The cutter is equipped with modern belts that do not require special care. It is only necessary to control them regularly and exchange them should you

see cracks or breaks on their surface. It is necessary to check on the tightening pulleys setting after the first 5 hours of operation, as the belt is being run-

in. It is necessary to check the tightening pulleys function during the running-up, in order to prevent belt damage caused by insufficient tension when the

belt extends. It is also important to check the function of the automatic disc brake during the running-up.

The correct belt transmission function is easy to check:

a) Turn on the wheel drive and let the cutter deal with a 10 cm terrain obstacle – e.g. a kerb.

b) The engine stalls when you press the wheel drive clutch quickly. The belt already starts to grip (the disc starts spinning) in just 1/3

step of the wheel drive clutch lever.

If you had problems with at least one of these, the tightening pulleys need adjustment.

2.5.4.1 Tightening pulleys adjustment

Seek authorised service in case you lack appropriate manual skills.

First: Dismantle the top plastic cover, so that you can see both belts (Pict.10) securing the forward movement of the machine. Try again to overcome

terrain irregularities and visually check belt slipping.

1) If the belt slipping occurs on the right side of the cutter, tighten it by unscrewing the bolt (3) at the cable

54

terminal in the direction of

the arrow (away from the frame) for approximately 1mm, and repeat the visual check as in a). Continue tightening until condition a) is met and

at the same time the cutter start moving forward while wheel drive clutch lever is loose. If the bolt (3) cannot be unscrewed any further, screw

it in completely against the direction of the arrow and hook the spring at the end of the cable into a further opening in the pulley arm. Repeat

tightening the belt until condition a) is met.

2) If there is belt slipping between the engine and gearbox, dtighten it with the tightening pulley (4). Loosen the pulley by loosening the

nut placed below the pulley. Use an appropriate tool (e.g. steel hook) to tighten the pulley in the direction of the arrow and tighten the nut while

the pulley is stretched. Then check the right function of the wheel drive.

In case the tightening pulleys cannot be adjusted to prevent belt slipping, it is necessary to exchange the belt.

52 The blades are double-sided; they can be turned around if necessary. The blades must never be damaged.

53 Insufficient bolt tightening usually destroys the hardened washer around which the blades spin.

54 You may also use the bolt attached to handlebar rail on the other side of the cable. In this case, screw the bolt in the direction away from the rail.

24

Loading...

Loading...